Your wheels are the engine of your bike, and the tire system you choose is the critical interface between that power and the road. For riders investing in performance carbon racing bike wheels, the decision between Clincher, Tubeless, and Tubular tire systems is fundamental. Each has distinct advantages, trade-offs, and philosophies. This guide cuts through the confusion to help you select the perfect system for your riding style, goals, and willingness to tinker.

1. Clincher: The Proven, Accessible Standard

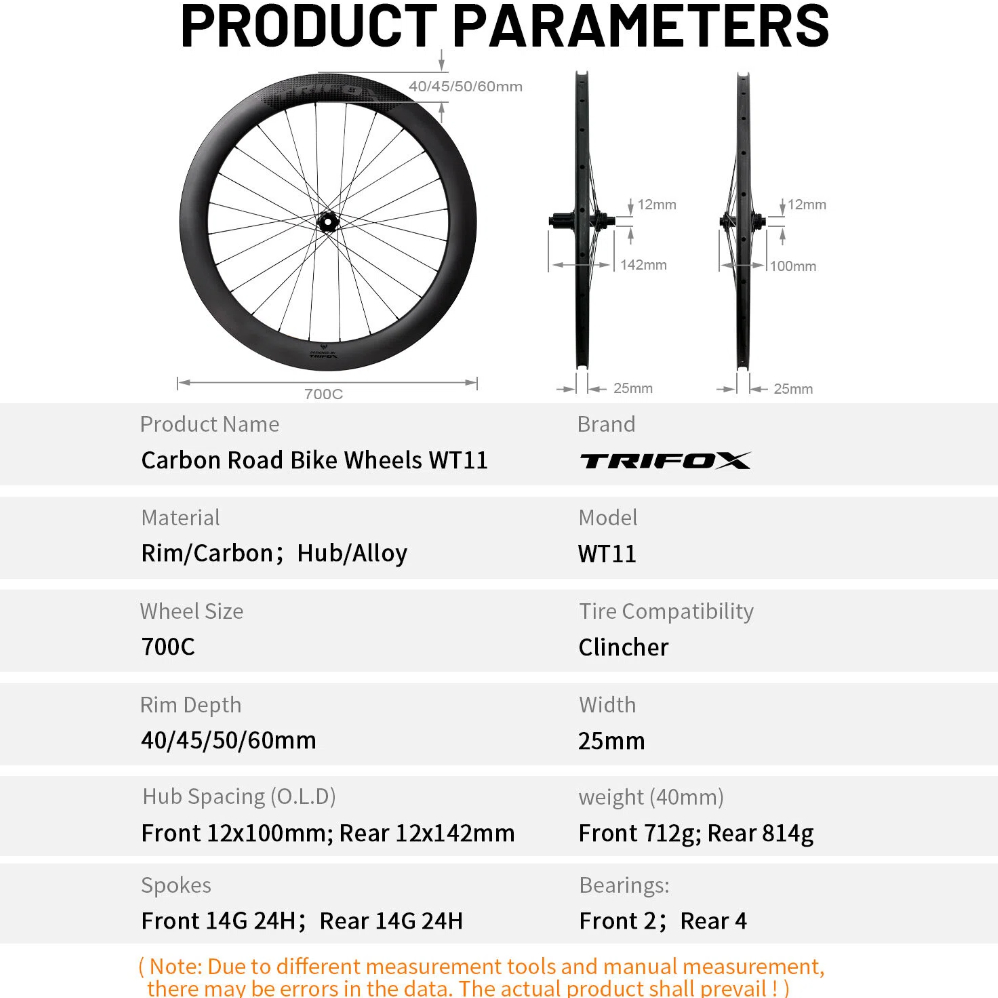

The clincher system is the most common and familiar. It uses a separate inner tube inside a tire that "clinches" onto a hooked rim bead, like the WT11 wheelset is designed for.

* Pros: Unmatched accessibility and convenience. Tires and tubes are widely available and inexpensive. Repairs are straightforward: find the puncture, patch or replace the tube, and you're rolling again. Installation is generally the easiest of the three systems, requiring only tire levers and a pump. It's the perfect, low-fuss choice for most recreational riders, commuters, and those new to high-performance road bicycle wheels.

* Cons: Requires an inner tube, which adds weight and rolling resistance. The tube is also the most vulnerable point for pinch flats (snake bites) if you hit a pothole at low pressure. At very high pressures, there's a slight risk of the tire blowing off the rim (though modern rims and tires make this extremely rare).

* Best For: Riders who prioritize ease of use, easy roadside repairs, and maximum compatibility. It's the reliable workhorse system.

2. Tubeless: The Modern Performance Benchmark

Tubeless technology, borrowed from mountain biking, has revolutionized road performance. It uses a special tire and sealed rim to create an airtight system without an inner tube. Sealant liquid inside the tire instantly plugs most small punctures.

* Pros: Superior puncture protection and ride quality. The absence of a tube eliminates pinch flats and allows you to safely run lower tire pressures (e.g., 60-80 psi vs. 90+ psi on clinchers). This dramatically increases comfort, grip, and rolling efficiency over rough surfaces. The sealant handles most small flats automatically, a huge advantage mid-ride.

* Cons: More complex setup and maintenance. Initial installation can be messy and often requires an air compressor or a high-volume pump to "seat" the tire bead onto the rim. Sealant dries out and needs replenishing every few months. Compatible tires and rims are required. Repairs for larger cuts can be more involved than simply swapping a tube.

* Best For: Performance-oriented riders seeking the best combination of comfort, grip, and flat protection for everyday training and racing. It's the ideal modern upgrade for carbon racing bike wheels.

3. Tubular: The Legendary Race-Day Specialist

Tubulars (or "sew-ups") are the oldest and most specialized system. The tire is a closed tube, stitched around an inner tube, and glued directly onto a smooth, hookless rim.

* Pros: Unbeatable ride feel and security at the limit. When properly glued, tubulars offer legendary ride quality—a supple, "connected" feel that many pros swear by. In a crash, they are less likely to roll off the rim than a clincher. They can also be ridden flat to a safe stopping point in a race.

* Cons: High cost, high complexity, and high commitment. Tires are expensive, and the gluing process is a meticulous, multi-day ritual requiring skill and patience. Repairs are difficult and time-consuming; most riders simply replace the entire tire. Swapping wheelsets is not a quick task.

* Best For: Almost exclusively competitive racers at the highest levels who have team support, prioritize the absolute pinnacle of ride quality and cornering confidence, and accept the significant hassle and cost. For the vast majority of riders, the performance gap to modern tubeless has narrowed considerably.

The Verdict: Making Your Choice

* Choose Clincher for simplicity, reliability, and hassle-free use.

* Choose Tubeless for the best all-around performance, combining flat protection, comfort, and speed for most serious riders.

* Choose Tubular only if you are a dedicated racer chasing every last percent of performance and have the support system to manage it.

For a wheelset like the disc-brake ready, carbon racing bike wheels WT11, starting with reliable clincher tires is a fantastic choice. As your confidence and demands grow, the same rims are often tubeless-ready, allowing you to easily upgrade to a tubeless system to unlock the next level of performance, making your road bicycle wheels faster and more comfortable than ever.

In mountain biking, individual component quality matters—but true performance emerges from how these parts work together. When you pair a premium carbon frame with a purpose-matched carbon fork, you unlock a level of synergy that transforms your entire ride. The combination of Trifox's SDY21 carbon hardtail frame and TMK200 rigid mtb fork 29 creates a unified system where stiffness, weight savings, and responsiveness multiply rather than simply add.

The foundation of this partnership is material harmony. Both the SDY21 frame and TMK200 fork are constructed from high-modulus unidirectional carbon fiber, using compatible resin systems and layup techniques. This shared material DNA ensures consistent flex characteristics and vibration damping throughout the front triangle. When frame and fork speak the same structural language, energy transfer becomes incredibly efficient. Every pedal stroke propels you forward with minimal loss, while trail vibrations are absorbed uniformly, reducing fatigue.

Geometry alignment is equally critical. The SDY21 frame is designed around modern trail metrics—a slack head angle, short chainstays, and optimized front-center measurement. The TMK200 fork complements this with precisely calculated offset and axle-to-crown length. Together, they create handling that's both stable at speed and nimble in corners. This isn't a generic fork bolted to any frame; it's a calibrated pairing where steering precision feels intuitive and predictable.

Weight optimization reaches its peak in this combo. The SDY21 frame utilizes strategic carbon layering to reinforce high-stress zones while trimming material elsewhere. Similarly, the TMK200 is engineered as one of the lightest mountain bike fork options in its category. When combined, the total weight savings at the front end significantly improves maneuverability. The bike feels more willing to change direction, easier to loft over obstacles, and generally more lively on the trail. This synergy makes the whole bike feel lighter than the sum of its parts.

Stiffness synchronization creates another performance multiplier. A stiff frame paired with a flexible fork (or vice versa) creates handling inconsistencies. With the SDY21 and TMK200, both components share similar torsional and lateral rigidity. This means when you lean into a corner or power through a rock garden, the front and rear of the bike respond as one cohesive unit. There's no lag or disconnection—just immediate, faithful tracking that builds rider confidence.

The practical benefits extend to assembly and maintenance. Designed as a matched system, the fork's tapered steerer integrates seamlessly with the frame's head tube. The Boost spacing aligns perfectly, and brake routing follows complementary paths. This compatibility eliminates installation headaches and ensures optimal performance from day one. Additionally, the shared aesthetic—clean carbon textures and minimalist branding—creates a visually unified machine that looks as fast as it rides.

Choosing a frame and fork as an integrated system, like the Trifox SDY21 and TMK200 bundle, represents a smarter approach than mixing and matching components. You're not just buying two separate parts; you're investing in a harmonious relationship engineered from the ground up. The result is a mountain bike that handles with a rare balance of efficiency, control, and pure fun. In the equation of performance, synergy is the ultimate multiplier, transforming capable components into an extraordinary complete bike.

For many riders, the quest for comfort leads to a simple conclusion: a softer saddle must be better. This instinct often backfires. A saddle that feels like a plush couch in the showroom can transform into an instrument of discomfort on a long ride. Why? Because true comfort isn't about maximum softness; it's about intelligent pressure distribution. The materials inside your saddle—foam, gel, and advanced composites—are engineered not just to cushion, but to create a stable, supportive platform that places pressure precisely where your body is designed to handle it.

The Problem with "Soft": The Hammock Effect

Imagine sinking into a soft sofa or a loose hammock. Initially, it feels great. But soon, your body sinks until it meets resistance, often concentrating force on your soft tissue and pelvic bones. A saddle with overly soft, uniform padding does the same. Your sit bones (ischial tuberosities) push through the soft material, bottoming out and creating intense pressure points. This lack of support can also lead to instability, chafing, and numbness. A comfortable bicycle seat doesn't invite you to sink in; it provides a firm, supportive platform to sit on.

Material Science: The Tools for Intelligent Support

Modern saddles use advanced materials to solve this problem, moving beyond a one-thickness-fits-all approach.

High-Density & Multi-Density Foam: The Precision Tool

This is the cornerstone of performance saddle design. Instead of a single soft layer, engineers use varying densities:

Firm, High-Density Zones: Located directly under your sit bones. This dense foam resists compression, providing a stable platform that prevents sinking and effectively supports your skeletal structure.

Softer, Lower-Density Zones: Placed in the surrounding areas and along the center channel. This foam absorbs vibrations and provides gentle cushioning without compromising the critical structural support of the firmer zones.

This "multi-density" approach is like having a custom-molded base layer: firm where you need support, forgiving where you need relief.

Gel Inserts: Targeted Damping

Gel is excellent at dissipating sharp impacts and high-pressure points in a static setting. However, its drawbacks are weight, poor breathability, and a tendency to create a "quicksand" feel if overused, absorbing energy and causing slight instability during pedaling. Therefore, in well-designed saddles like the Trifox Comfortable Saddle, gel is used strategically as an insert, often in the nose or specific high-pressure areas, to add a layer of dampening on top of a supportive foam base. It's a supplement, not the main structure.

Shaped & Variable-Thickness Padding: The Holistic Approach

The most advanced designs combine material density with physical shape. Through pressure mapping and biomechanical research, saddle padding is carved to be thicker in supportive areas and thinner or absent in zones that require relief (like the critical perineal area). This 3D shaping ensures the right amount of material is in the right place, working in concert with the saddle's shell to create a unified support system.

The Trifox Design Philosophy: Engineered Comfort

The Trifox PU Leather Comfortable Saddle exemplifies this intelligent approach to pressure management. It moves beyond the old "soft vs. hard" debate by focusing on structured support.

PU Leather & Resilient Padding: The high-quality PU leather cover provides durability and a slight give, while the underlying cushioning system is designed for resilience and support over many miles.

Ergonomic Shape is Key: The saddle's shape features a central relief channel, a fundamental design element that alleviates soft-tissue pressure by ensuring no contact or minimal pressure in the midline. This works in tandem with the padding to direct support to the sit bones.

Focused on Lasting Support: The goal isn't initial plushness that fades, but consistent, dependable support that reduces fatigue and hotspots, allowing you to focus on your ride, not your discomfort.

Support Over Softness

Choosing a bicycle saddle based on padding thickness alone is a common mistake. The science of comfort is about differential support—using materials like multi-density foam and strategic shaping to create a stable platform that distributes your weight efficiently. It’s the difference between sinking into a problem and sitting on a solution. When your sit bones are properly supported, pressure is healthily distributed, and soft tissues are relieved, you unlock the true potential for a comfortable bicycle seat that enhances, rather than hinders, every ride. Look for design intelligence, not just squishiness.

El rodamiento del eje de pedalier es el corazón de la transmisión de tu bicicleta. Cuando llega el momento de una actualización, el debate entre los modelos cerámicos de alta gama y los fiables de aluminio es inevitable. ¿Vale la pena la prima por la cerámica, o un eje de pedalier de aluminio bien hecho como el Trifox TRBB68 es la opción más inteligente? Examinemos los hechos.

1. Fricción y Eficiencia: La Base de la Afirmación

Los rodamientos cerámicos presumen de un coeficiente de fricción más bajo: pruebas de laboratorio muestran hasta un 25-30% menos que el acero. Sin embargo, el ahorro de potencia en el mundo real es sutil, a menudo de solo 1-3 vatios. Para la mayoría de ciclistas, esto es imperceptible. Un eje de aluminio de precisión con rodamientos lisos, como el Trifox TRBB68, proporciona un rendimiento excepcionalmente eficiente para casi todas las aplicaciones, haciendo que la ventaja cerámica sea más relevante para corredores de élite.

2. Durabilidad y Longevidad: Una Compensación

* Resistencia a la Corrosión: Gana la Cerámica. Las bolas cerámicas no se oxidan, una ventaja para ciclistas en todas las condiciones.

* Resistencia al Impacto: Gana el Aluminio/Acero. Bajo carga alta o impacto (común en MTB), la dureza de la cerámica puede llevar a fragilidad y grietas. Un eje de carcasa de aluminio de calidad con rodamientos de acero es generalmente más robusto para el ciclismo real.

3. Peso: Una Diferencia Insignificante

El peso no debería ser un factor. Un eje de pedalier de 68mm de aluminio estándar como el Trifox TRBB68 pesa 94-98g. Un modelo cerámico comparable a menudo pesa casi lo mismo, ya que el pequeño ahorro de peso de las bolas cerámicas se compensa con otros componentes.

4. Mantenimiento y Sensibilidad: El Coste Oculto

Para lograr su potencial, los rodamientos cerámicos requieren un alineamiento de instalación casi perfecto y un ambiente limpio. Son menos tolerantes a asientos de rodamiento desalineados. Los ejes de aluminio con rodamientos estándar son mucho más indulgentes con las variaciones menores de instalación, lo que los convierte en una opción más práctica para mecánicos caseros.

5. Precio y Valor: El Decisor Final

Esta es la diferencia más clara. Un eje de pedalier cerámico puede costar 5 a 10 veces más que un modelo de aluminio premium.

* La Cerámica es para: Corredores de élite que persiguen cada vatio, y entusiastas que valoran las "ganancias marginales".

* El Aluminio es para: La gran mayoría de ciclistas. Una opción de alta calidad como el Trifox TRBB68 ofrece un valor excepcional, mecanizado de precisión y rodamientos sellados fiables, liberando presupuesto para actualizaciones con retornos más notables (como mejores neumáticos).

El Veredicto: Realidad Basada en Datos

La ventaja de fricción de la cerámica es real pero mínima para no corredores. Cuando consideras su mayor costo, sensibilidad y compensaciones de durabilidad, la proposición de valor se reduce. Para un componente que debe soportar condiciones del mundo real, el rendimiento equilibrado y el valor excepcional de un eje de pedalier de aluminio moderno son difíciles de superar. Productos como el Trifox TRBB68 ofrecen una suavidad y fiabilidad excelentes, permitiéndote centrarte en el recorrido, no solo en ganancias marginales.

For mountain bikers seeking both performance and comfort, the question of vibration absorption looms large. Many cyclists have heard claims about carbon fiber's ability to "soak up" trail vibrations, but how much of this is marketing hype versus scientific reality? Examining frames like the Trifox SDY21 Lightweight Carbon MTB Hardtail Frame reveals a complex interplay of materials science that impacts ride quality, whether building a modern 29 in mountain bike frame or a minimalist single speed bike frame.

The Material Science: Why Carbon Fiber Behaves Differently

Carbon fiber's vibration-damping capability stems from its composite nature. Unlike homogeneous materials like aluminum, carbon fiber consists of microscopic filaments in a resin matrix, creating interfaces where vibrational energy dissipates. When vibrations travel through the carbon frame, they navigate complex interfaces, with each boundary absorbing energy—creating measurable damping that riders perceive as improved mountain bike comfort, whether on a geared bike or single speed bike frame.

Structural Damping vs. Material Damping

Crucial to distinguish between structural damping (from frame design) and material damping (from inherent properties). Carbon fiber excels at material damping due to its composite nature. The SDY21 harnesses this through careful carbon layup, optimizing both stiffness for power transfer and compliance for vibration absorption. This approach creates a hardtail frame that feels stiff during pedaling but forgiving on trail imperfections, beneficial for both 29 in mountain bike frame and single-speed configurations.

Frequency Matters: Which Vibrations Get Absorbed

Carbon fiber doesn't dampen all frequencies equally. Higher frequency vibrations from trail chatter are most effectively absorbed—precisely what causes hand numbness and muscle fatigue. The SDY21 addresses this spectrum through balanced design: carbon construction handles high-frequency damping while geometry manages larger impacts. This explains less fatigue on carbon hardtails, particularly important for 29 in mountain bike frame setups where wheel dynamics interact differently with trail vibrations, affecting overall ride quality.

The Layup Process: Engineering Vibration Pathways

How carbon fiber is laid up significantly impacts vibrational characteristics. The SDY21 employs a sophisticated combination: high-stress areas use unidirectional fibers for optimal power transfer—critical for both racing bikes and single speed bike frame builds. Comfort-focused areas incorporate woven fabrics that enhance vibration damping technology without compromising structure. This intelligent carbon layup science delivers both efficiency and comfort in modern mountain bike frame design.

Real-World Implications: Less Fatigue, More Control

Practical benefits appear during extended trail sessions. Reduced vibration transmission means less hand and arm fatigue, allowing better control—particularly valuable on hardtails and crucial in a single speed bike frame where riders cannot shift to easier gears when fatigued. This trail vibration reduction also improves traction; by filtering vibrations, carbon frames maintain more consistent tire contact, especially valuable in loose conditions and beneficial for 29 in mountain bike frame configurations where larger wheels benefit from stable tracking.

Comparing Materials: Carbon's Advantage

Aluminum transmits vibrations efficiently with minimal damping, explaining why aluminum hardtails feel "harsh"—especially noticeable in minimalist single speed bike frame builds. Carbon fiber occupies a unique middle ground: stiffer than aluminum in specific directions while providing better carbon fiber vibration damping through its composite nature. This advantage proves particularly evident in modern 29 in mountain bike frame designs where carbon helps mitigate sometimes-harsher feedback from larger wheels.

Conclusion: Science Confirms the Ride Experience

Whether carbon fiber really absorbs vibrations finds answer in both laboratory measurements and rider experiences. The material's composite structure converts vibrational energy through microscopic interfaces—scientifically valid and perceptually significant across configurations. Frames like the Trifox SDY21 demonstrate how carbon engineering balances stiffness, weight, and durability while delivering tangible benefits: less fatigue, better control, and more enjoyable trail time—whether building a versatile 29 in mountain bike frame or a simplified single speed bike frame for uncomplicated riding pleasure.

Think building a capable, lightweight hardtail requires breaking the bank? Think again. The sub-$250 frame market is hotter than ever, offering surprising performance for riders seeking value without sacrificing fun. We scrutinized options, and one standout shines: the Trifox MFM200 Carbon Hardtail Frame. Here’s why it’s a budget hero:

The Carbon Game-Changer (Yes, at $227!)

The MFM200 shatters expectations by delivering a full carbon fiber frame at an astonishing price point. Forget heavy steel or flexy aluminum – this frame offers the core benefits of carbon:

Ultralight Build: Weighing in around 1200g (size dependent), it sheds serious pounds compared to alloy frames at this price. That translates directly to easier climbing and a livelier, more responsive feel on every trail.

Stiffness for Speed: Carbon construction ensures excellent pedaling efficiency. Power transfer is direct, minimizing wasted energy when you stomp on the pedals, whether sprinting or grinding uphill.

Tuned Trail Compliance: While stiff laterally, carbon can offer subtle vertical flex. The MFM200’s design helps absorb smaller bumps and chatter, reducing fatigue on longer rides and rough sections, making it more capable than its price suggests.

Modern Geometry for Real Trails

Trifox didn't skimp on contemporary design:

Slack Head Tube Angle (~66-67°): Boosts confidence on descents, improving stability when things get steep or rough.

Steep Seat Tube Angle (~74-75°): Positions you efficiently over the pedals for better climbing traction and comfort.

Reach & Wheelbase: Balanced numbers provide a stable yet maneuverable ride suitable for aggressive trail riding and XC adventures.

Smart Build Compatibility

The MFM200 plays nice with widely available, affordable components:

Boost Hub Spacing (148x12mm rear): Ensures stiffness and compatibility with modern wheelsets.

Internal Cable Routing: Clean looks and protection for dropper posts and derailleurs.

Tapered Headtube: Fits modern, stiff forks for precise steering.

Threaded Bottom Bracket: A huge win for reliability and ease of maintenance – no creaky press-fits!

Value Verdict: The Trifox MFM200

Finding a new carbon frame under $230 feels almost unreal. The Trifox MFM200 delivers the core advantages of carbon – significant weight savings, efficient power transfer, and surprisingly good trail manners – wrapped in modern, capable geometry. While you might find minor finish differences compared to premium frames, the fundamental performance is undeniable.

Is it perfect? Consider:

Finish: Expect functional over flawless – cosmetics might be simpler.

Hardware: Bearings and bolts are adequate, but upgrading later is easy.

Build Cost: Remember, the frame is just the start! Factor in fork, drivetrain, wheels, etc.

The Bottom Line:

For riders demanding a lightweight, efficient, and modern hardtail platform without blowing the budget, the Trifox MFM200 is a revelation. It proves you don't need $1000+ to get a frame that unlocks hardtail heroics. Pair it with smart component choices, and you’ve got a trail-taming machine that punches way above its weight class. Budget hardtails just leveled up!

Remember when carbon fiber was reserved for pro pelotons and deep-pocketed racers? Not anymore. Mountain biking is witnessing the unstoppable rise of carbon, transforming trails from XC loops to gnarly enduro descents. Brands like Trifox are making this once-exotic material accessible, proving carbon MTBs aren't just lighter – they're better riding machines. Here's why the shift is seismic:

Featherweight Flight: This is the headline. Carbon frames slash pounds off alloy counterparts. Less weight means easier climbing, quicker acceleration, and less fatigue over long days. You carry the bike less; the bike carries you more. Trifox's carbon hardtails and full-suspension rigs exemplify this advantage, turning arduous ascents into achievable efforts.

Stiffness Meets Sensation: Carbon isn't just light; it's incredibly tuneable. Engineers craft frames with targeted stiffness where it matters most: the bottom bracket for efficient pedaling, the head tube for precise steering. Yet, carbon's magic lies in its ability to also offer vertical compliance. It absorbs smaller trail chatter better than alloy, reducing arm and leg fatigue, letting you ride harder, longer.

Strength You Can Trust: Forget the "fragile" myth. Modern carbon layups create structures incredibly resistant to impacts and fatigue. When designed correctly (like Trifox's robust mountain frames), carbon handles rock strikes, drops, and rough terrain with impressive resilience. It won't dent like aluminum and shrugs off corrosion.

Ride Refined: The combination of lightness, stiffness, and subtle flex translates to a more connected, responsive, and lively feel. You feel the trail without being beaten by it. Carbon bikes track better through corners, feel more nimble in the air, and offer a directness that boosts confidence when pushing limits.

Trifox: Bringing Carbon to the Trail

Brands like Trifox are crucial to this rise. By leveraging efficient manufacturing and direct-to-consumer models, they deliver high-performance carbon mountain bikes at astonishingly competitive prices. Whether it's their agile carbon hardtails perfect for XC and trail blasting, or their capable full-suspension platforms, Trifox proves you don't need a pro contract to experience the carbon revolution.

The Verdict: Not Just a Trend, The Future

The rise of carbon fiber in mountain biking isn't just hype; it's a fundamental shift driven by tangible performance benefits. It offers a superior blend of weight, strength, stiffness, and ride quality that alloy struggles to match. As manufacturing advances and brands like Trifox make it more accessible, carbon is becoming the material of choice for riders seeking every advantage on the trail. It’s not about replacing alloy entirely, but about offering a compelling, high-performance option that’s redefining what’s possible on two wheels. Ready to feel the difference? Explore the carbon evolution: Discover Trifox Mountain Bikes.

That stock saddle on your road bike? It served its purpose getting you started. But if you're chasing performance, comfort, or simply a more refined ride, upgrading to a full-carbon saddle like the Trifox CS200 is a game-changer. Forget the misconception that carbon is harsh – modern designs blend featherweight efficiency with surprising comfort. Here's why the switch is worth it:

1. The Weight Weenie Wins: This is the obvious one. At a claimed 120 grams, the Trifox CS200 utterly demolishes typical alloy-railed saddles (often 250g+). Shedding 100+ grams directly off your bike, especially high up and at the contact points, makes a tangible difference. It's pure acceleration, easier climbing, and the satisfaction of marginal gains realized. Every watt feels more efficient.

2. Stiffness = Power Transfer: Carbon fiber's inherent stiffness isn't just for weight savings. It means virtually zero flex under power. When you stomp on the pedals, every ounce of energy goes into propelling you forward, not lost compressing padding or flexing the shell. You'll feel a more direct, connected drive, especially during sprints and out-of-the-saddle efforts.

3. Engineered Comfort (Yes, Really!): "Carbon must be hard!" is the biggest myth. Saddles like the CS200 use carefully sculpted shapes, strategic flex zones in the carbon base, and minimal high-density padding precisely where needed. This provides targeted support to your sit bones, reducing pressure on soft tissue. Less padding can actually mean less numbness on long rides, as your weight is correctly distributed. The shape is key, and many find carbon shells conform better over time.

4. Breathability Matters: Ever finished a long ride feeling swampy? Full-carbon bases are inherently perforated or designed with significant cutouts/channels (like the CS200). This promotes airflow, drastically reducing heat and moisture buildup. Enhanced ventilation equals greater comfort and reduced friction, ride after ride.

5. Durability & Low Maintenance: Carbon fiber is incredibly resilient to fatigue and corrosion. Unlike leather or synthetic covers that can degrade, or rails that can rust, a quality carbon saddle shrugs off sweat, weather, and miles. It requires minimal upkeep beyond wiping clean.

The Trifox CS200: A Prime Example

The Trifox CS200 exemplifies these benefits perfectly:

- Ultralight 120g: Significant weight savings.

- Full Carbon Shell & Rails: Maximizes stiffness and durability while minimizing weight.

- Strategic Padding: Minimal, high-rebound foam for targeted comfort without bulk.

- Central Cutout: Enhances breathability and relieves perineal pressure.

- Aerodynamic Shape: Sleek design complements a performance road bike.

Is it for Everyone?

Like any saddle, fit is paramount. A carbon saddle's shape needs to match your anatomy. If the stock shape works for you, upgrading to carbon refines it. If not, focus on finding the right shape first, then consider carbon for the performance benefits. The Trifox CS200 offers a popular, performance-oriented profile.

The Upgrade Verdict:

Upgrading to a carbon saddle isn't just about shaving grams; it's about enhancing the fundamental connection between you and your bike. The blend of dramatic weight reduction, efficient power transfer, surprising comfort through intelligent design, and superior breathability creates a noticeably better riding experience. If you're ready to feel more connected, efficient, and comfortable, especially on demanding rides, a saddle like the Trifox CS200 is a worthy investment. It transforms a crucial contact point from a necessary component into a performance asset. Make the switch and feel the difference!

Forget "just" improved stopping power – switching to a dedicated disc brake wheelset unlocks a cascade of performance benefits that fundamentally elevate your road riding. It's not an incremental upgrade; it's a transformation in control, confidence, and capability.

Why Disc Wheelsets Rule the Road:

1. Unshakeable Confidence, Anywhere, Anytime: Rim brakes falter in wet grit or on long, steep descents. Discs deliver consistent, powerful, and modulated braking performance regardless of weather, road grime, or gradient. This translates directly to riding faster with more control when it matters most.

2. Aerodynamic & Structural Advantages: Free from the need for a braking surface, disc wheelsets allow for wider, deeper, and more aerodynamically optimized rim profiles. This reduces drag for free speed. The rim itself is also stronger without the wear surface, enabling lighter constructions and improved impact resistance.

3. Tubeless Paradise: Disc wheelsets are the perfect partners for tubeless tires. Wider rims create a better tire profile for lower rolling resistance, enhanced grip, and the holy grail: fewer flats at lower pressures. No more worrying about brake track wear from heat during hard descents either.

4. Future-Proof Performance: The industry standard is clear. Disc brakes dominate new road bikes. Investing in a quality disc wheelset ensures compatibility with the latest frames and groupsets, protecting your upgrade path.

The Trifox WT11: Performance Engineered for Disc:

The WT11 Disc Brake Centerlock Clincher Carbon Wheelset embodies these advantages:

- Lightweight Carbon Construction: Prioritizes acceleration and climbing response.

- Optimized Aero Depth: Balances speed and crosswind stability.

- Wider Rim Profile: Enhances tire performance and supports tubeless setups seamlessly (valves included!).

- Reliable Centerlock Interface: Ensures secure rotor mounting and easier maintenance.

- Stiffness & Durability: Engineered for powerful sprints and demanding riding.

Who Wins with Disc Wheels?

- All-Weather Warriors: Ride confidently rain or shine.

- Descenders & Climbers: Brake later, descend faster, climb without rim heat worries.

- Speed Seekers: Leverage superior aero and tubeless efficiency.

- Tech Adopters: Invest in the modern standard.

Ready for Uncompromised Control & Speed?

Upgrade your stopping power, unlock aerodynamic gains, embrace tubeless simplicity, and future-proof your ride. Disc wheelsets aren't just better brakes; they're the foundation for a faster, safer, and more enjoyable road experience.