Selecting the best bicycle saddle can significantly enhance your riding experience, offering the perfect blend of comfort, performance, and durability. While personal preferences and riding styles play a crucial role, there are certain features every rider should consider when choosing the right saddle.

Comfort is paramount. A saddle that doesn't fit well can lead to discomfort and even pain during long rides. It's essential to choose a saddle that aligns with your body's anatomy. The shape and width should offer ample support to your sit bones while the nose should be shaped to prevent pressure on soft tissues.

The Trifox CS100, for instance, features a thoughtful nose design that promotes better blood circulation and prevents numbness, making it a superb choice for extended rides.

Weight is another critical factor, especially for competitive cyclists or those who frequently engage in long-distance biking. A lighter saddle can make a noticeable difference in your bike's overall performance.

Carbon fiber saddles, like the Trifox CS100, are favored for their excellent strength-to-weight ratio. Weighing just 106 grams, this saddle reduces the overall weight of the bike, enhancing speed and control without compromising durability.

Material plays a significant role in saddle performance. Carbon fiber is not only lightweight but also offers remarkable vibration dampening abilities.

The Trifox CS100's carbon fiber construction absorbs shocks and vibrations, delivering a smoother and more comfortable ride across different terrains. This feature is especially beneficial for those who frequently cycle on rough or uneven surfaces.

Ventilation should not be overlooked. A saddle with a vented design helps in maintaining airflow during rides, keeping the rider cool and preventing sweat buildup. The Trifox CS100 incorporates a vent design that enhances breathability, ensuring a more pleasant and dry riding experience.

Ultimately, the choice of saddle should also reflect your riding style. Whether you're a road cyclist, a commuter, or an off-road enthusiast, your saddle needs to complement your riding habits.

A well-fitted saddle like the Trifox CS100, which offers a blend of comfort features and performance enhancements, can significantly improve your cycling experience.

In conclusion, finding the best bicycle saddle involves balancing comfort, weight, material, and design to suit your personal needs. The Trifox CS100 exemplifies these qualities with its lightweight carbon fiber construction, ergonomic design, and advanced features, making it a top choice for cyclists seeking to optimize their ride. By taking the time to select a saddle that aligns with your anatomy and riding style, you can enjoy a more comfortable and efficient cycling journey.

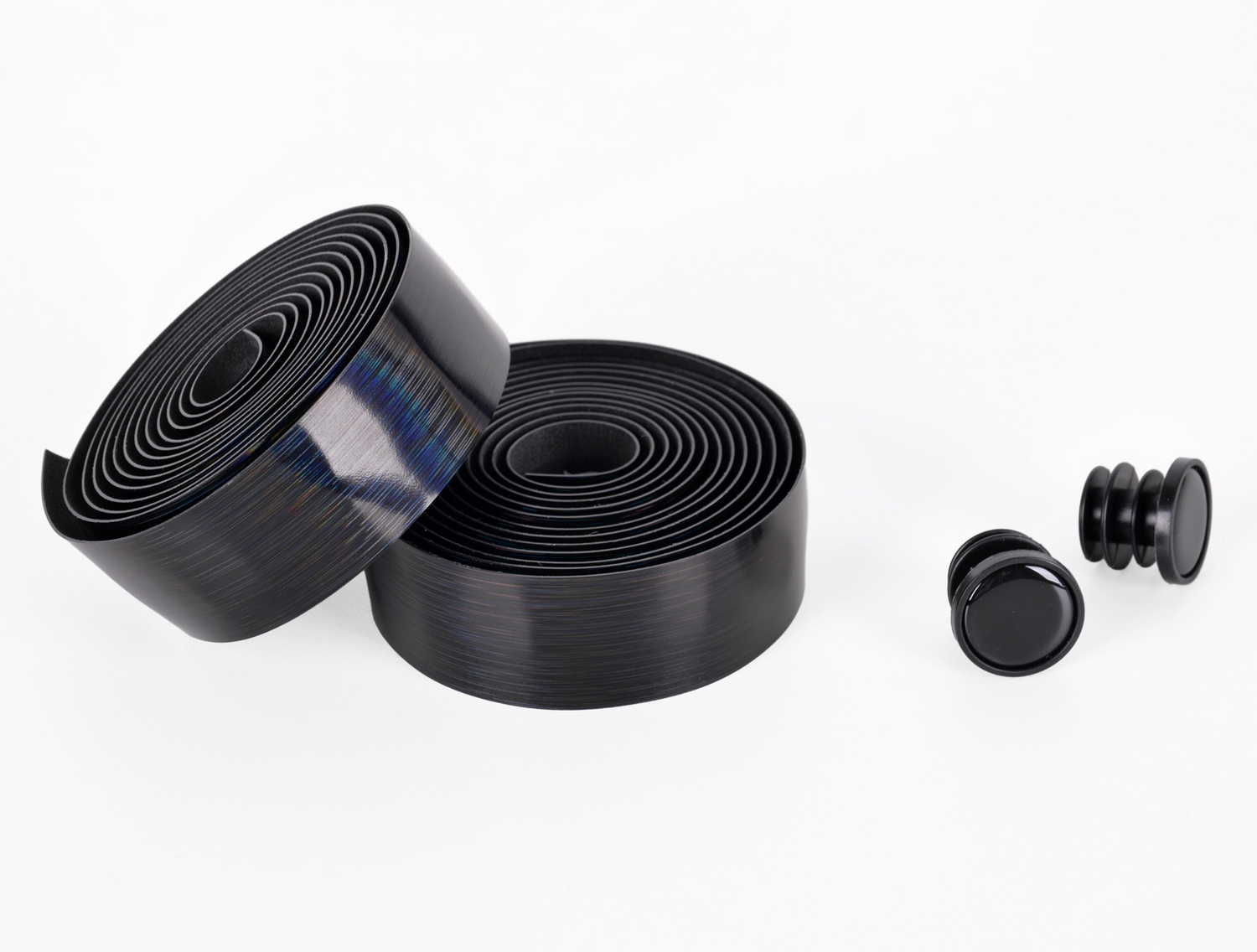

Cyclists often seek ways to enhance their performance and comfort, and taping aero bars is a simple yet impactful method to achieve this. Aero bars, used primarily by triathletes and time trialists, offer aerodynamic advantages by allowing cyclists to assume a more streamlined position.

Taping these bars with high-quality handlebar tape, such as Trifox Bike's BHT100, further enhances grip, comfort, and aerodynamics, making it an essential practice for serious cyclists.

One of the primary benefits of taping aero bars is improved grip. During long rides or competitive events, maintaining a secure hold on the bars is crucial, especially in adverse weather conditions.

The BHT100 tape, made from EVA and PU leather, provides a textured surface that offers excellent grip, even when wet. This ensures that cyclists can maintain control and stability, which is vital for safety and performance.

In addition to grip, comfort is significantly enhanced through taping. The padded nature of handlebar tape acts as a cushion against road vibrations, reducing hand fatigue and discomfort. This is particularly beneficial during long-distance rides or time trials where comfort can directly influence endurance and performance.

Taping also contributes to the aerodynamics of the aero bars. By creating a smooth surface, tape minimizes air resistance, allowing cyclists to maintain their aerodynamic posture without interruptions. This subtle yet effective improvement can lead to time savings during races.

Here’s a step-by-step guide on how to tape your aero bars effectively:

1. Preparation: Begin by cleaning the aero bars thoroughly to remove any dirt or grease. This ensures that the tape adheres properly.

2. Application: Start at the end of the aero bars, securing the tape with a small overlap. Stretch the tape slightly as you wrap it tightly around the bars, ensuring each wrap overlaps the previous one by half. This technique prevents gaps and ensures full coverage.

3. Finishing Touches: Once you reach the top of the bars, trim any excess tape and secure the end with the finishing tape provided. Ensure the tape is smooth and securely fastened to prevent unraveling during rides.

Trifox Bike's BHT100 tape is an excellent choice for taping aero bars. Its durability and cushioning provide both comfort and performance enhancements. With easy installation and a reliable grip, it is designed to meet the demands of cyclists at any level.

In conclusion, taping aero bars offers tangible benefits in terms of grip, comfort, and aerodynamics, making it a valuable practice for cyclists. By using high-quality tape like Trifox Bike's BHT100, riders can optimize their aero bars for superior performance and comfort, ensuring a more enjoyable and efficient cycling experience.

In the world of cycling, every component plays a vital role in enhancing the overall riding experience. One such component, often overlooked but equally important, is the quick release seatpost clamp. These clamps provide a range of benefits that can significantly improve convenience and versatility for cyclists.

One of the primary advantages of quick release seatpost clamps is their ease of adjustment. Unlike traditional clamps that require tools to adjust, quick release clamps allow cyclists to change seat height effortlessly, without the need for any tools. This is particularly beneficial for riders who frequently switch between different terrains or cycling styles.

For instance, transitioning from a steep hill climb to a flat road may necessitate a different saddle height for optimal comfort and performance. With a quick release clamp, these adjustments can be made swiftly and on the go.

Convenience is another major benefit. For cyclists who share a bike with family or friends, the ability to quickly adjust the seatpost to fit different riders’ heights is invaluable. This feature ensures that everyone can ride comfortably, reducing the risk of discomfort or injury due to improper seat height.

Versatility is also enhanced with quick release seatpost clamps. Whether you're commuting, racing, or mountain biking, the ability to adjust your seat quickly can adapt to varying demands and conditions. This flexibility can improve ride quality and efficiency, allowing you to maintain optimal posture and power output regardless of the scenario.

However, while quick release seatpost clamps offer numerous benefits, there are potential drawbacks to consider. They might be less secure compared to traditional clamps, potentially leading to the seatpost slipping during intense rides. To mitigate this, it’s crucial to ensure that the clamp is properly tightened before setting off. Regular checks and maintenance can also help maintain its reliability and performance.

Trifox Bike, renowned for its high-quality cycling components, offers a dependable quick release seatpost clamp that stands out for its durability and performance. Designed with precision engineering, Trifox’s clamp provides a secure fit while allowing for easy adjustments, making it a trusted choice for cyclists seeking both convenience and reliability.

In conclusion, quick release seatpost clamps offer significant advantages in terms of ease of use, convenience, and adaptability. By allowing for rapid seat height adjustments, they enhance the cycling experience, making each ride more enjoyable and efficient. Trifox Bike’s offering in this category exemplifies these benefits, providing cyclists with a reliable and versatile solution.

Upgrading your road bike's wheelset can significantly enhance your cycling performance, providing not only improved speed and efficiency but also better handling and ride quality. A well-chosen wheelset upgrade can be one of the most impactful modifications you make to your bike, transforming your riding experience.

Benefits of Upgrading Your Wheelset:

1. Increased Speed and Efficiency: Lighter wheels reduce rotational weight, making it easier to accelerate and maintain speed. Aerodynamic wheelsets minimize air resistance, allowing for smoother, faster rides.

2. Enhanced Ride Quality: High-quality wheelsets offer better responsiveness and smoother handling. They can absorb road vibrations more effectively, leading to a more comfortable ride over long distances.

3. Improved Durability: Upgrading to a robust wheelset ensures greater reliability and longevity, especially crucial for riders tackling various terrains and conditions.

Key Factors to Consider When Choosing a New Wheelset:

1. Material: Wheelsets are commonly made from carbon or alloy. Carbon wheels are lighter and more aerodynamic, ideal for competitive cyclists. Alloy wheels, such as those from TRIFOXBIKE, offer a great balance of performance and affordability, making them a favorite among many cyclists.

2. Rim Depth: Deeper rims provide aerodynamic benefits, making them suitable for flat terrains and time trials. However, they may be susceptible to crosswinds. Shallower rims are more versatile and handle better in varied conditions.

3. Spoke Count and Pattern: More spokes generally mean a stronger wheel, which is beneficial for heavier riders or rough terrain. The pattern and tension affect wheel strength and aerodynamics.

4. Compatibility: Ensure the new wheelset is compatible with your existing bike components, such as the cassette and brakes (rim or disc).

Tips for Installation and Maintenance:

1. Professional Installation: Have your new wheelset installed by a professional or follow detailed instructions to ensure proper alignment and tension, which are critical for performance and safety.

2. Regular Maintenance: Keep your wheels clean and free of debris. Regularly inspect for any signs of wear or damage, and ensure spokes are properly tensioned.

3. Tire Pressure: Maintain optimal tire pressure for your new wheels to enhance performance and prevent flats.

TRIFOXBIKE's alloy road wheels are an excellent example of a high-quality upgrade. Designed for reliability and performance, these wheels can elevate your cycling experience significantly. To explore TRIFOXBIKE's alloy road wheels and find the perfect fit for your cycling needs, visit their product page: TRIFOXBIKE Alloy Road Wheels.

By carefully selecting and maintaining your upgraded wheelset, you can enjoy a substantial boost in your road biking performance, making every ride faster, smoother, and more enjoyable.

Selecting and adjusting your bicycle seat saddle is crucial for a comfortable and efficient ride, regardless of whether you're a casual cyclist or a competitive racer.

A properly chosen and adjusted saddle can make a significant difference in your cycling experience by enhancing comfort and performance, preventing discomfort, and even minimizing the risk of injury.

1. Importance of Saddle Selection:

Choosing the right saddle is about balancing comfort with performance. A saddle that matches your riding style and body anatomy can improve your pedaling efficiency and help you maintain a proper riding posture. The right saddle also alleviates pressure points, reducing the likelihood of numbness and discomfort during long rides.

2. Factors to Consider When Selecting a Saddle:

Saddle Shape and Width: Consider the shape and width that best suits your anatomy. Wider saddles offer more support for casual riders, while narrower, elongated saddles tend to favor performance-oriented cyclists.

Padding and Material: The level of padding and the material of the saddle affect comfort. Gel padding offers plush comfort, while foam provides a firm yet supportive ride. Carbon saddles, like those from TRIFOXBIKE, offer a lightweight option that balances support with performance benefits.

Cut-out or Groove Design: Saddles with a cut-out or central groove help alleviate pressure on sensitive areas, enhancing comfort for long-distance riders.

Riding Style: Your riding style—whether road cycling, mountain biking, or commuting—affects saddle choice. Road cyclists often prefer lightweight, minimalistic designs, while mountain bikers might opt for more robust, cushioned options.

3. Tips for Adjusting Your Saddle:

Height Adjustment: Ensure the saddle height allows for a slight bend in the knee at the bottom of the pedal stroke. This promotes efficient power transfer and reduces strain on the knees.

Fore and Aft Position: Adjust the saddle's horizontal position so that when the pedal is at 3 o'clock, your knee is directly over the pedal spindle. This balance aids in efficient pedaling and reduces muscle fatigue.

Tilt Angle: A level saddle is generally best for most riders. However, slight adjustments can enhance comfort. A slight upward tilt may relieve pressure on the hands, while a downward tilt can ease lower back tension.

TRIFOXBIKE offers an excellent example with their carbon bike saddle, designed for both comfort and performance. This saddle is crafted with lightweight carbon materials, offering a sleek design that enhances bike aesthetics and riding efficiency. To explore TRIFOXBIKE's saddle offerings, visit their product page: TRIFOXBIKE Carbon Bike Saddle.

By carefully selecting and adjusting your bicycle saddle, you can transform your cycling experience, ensuring every ride is as comfortable and efficient as possible.

When it comes to upgrading your cycling components, a carbon seatpost is a fantastic choice for enhancing performance and comfort. Chinese manufacturers have become significant players in the cycling industry, offering high-quality carbon seatposts at competitive prices. Here's how to evaluate and choose the right Chinese carbon seatpost for your bike.

1. Benefits of Carbon Seatposts:

Carbon seatposts are renowned for their lightweight properties, which significantly reduce the overall weight of your bike. This can enhance acceleration and climbing performance.

Additionally, carbon's ability to absorb road vibrations results in a smoother and more comfortable ride, reducing fatigue on longer journeys. The flexibility of carbon also provides better shock absorption, which is particularly beneficial on rough terrains.

2. Key Factors to Consider:

Weight and Strength: Look for a seatpost that balances weight with strength. While carbon is naturally lighter than aluminum, ensure the seatpost can withstand your weight and the demands of your cycling style.

Diameter and Length: Ensure the seatpost's diameter matches your bike's seat tube and that the length is appropriate for your preferred saddle height.

Clamp Design: A secure and easy-to-adjust clamp is crucial for maintaining saddle position and comfort. Look for designs that offer precise adjustments and a firm grip.

Finish and Quality: Evaluate the quality of the carbon finish. A high-quality seatpost will have a uniform appearance without blemishes or imperfections that could compromise strength.

3. Tips for Choosing a Reliable Chinese Manufacturer:

Reputation and Reviews: Research the manufacturer's reputation in the cycling community. Customer reviews and expert opinions can provide insights into the product's reliability and performance.

Quality Assurance: Select manufacturers that offer quality assurance and adhere to international cycling standards. This ensures you're getting a product tested for safety and durability.

Warranty and Support: A good manufacturer will provide a warranty and customer support, giving you confidence in your purchase.

TRIFOXBIKE is an excellent example of a reliable Chinese manufacturer, renowned for their high-quality carbon seatposts. Their offerings are designed with precision, focusing on lightweight construction and durability to enhance cycling performance. With a range of sizes and designs, their seatposts cater to various cycling needs and preferences.

To explore TRIFOXBIKE's range of seatposts and find the perfect match for your bike, visit their product page: TRIFOXBIKE Seatposts. By carefully evaluating your options and choosing a reputable manufacturer, you can enjoy the numerous benefits of a carbon seatpost, elevating your cycling experience to new heights.

Selecting the perfect XS frame road bike is crucial for cyclists who seek efficiency, comfort, and optimal performance.

The frame size is one of the most important factors affecting how well you can ride, especially for those with smaller builds. Here's how to ensure you choose the right XS frame for an efficient ride.

1. Importance of Frame Size:

The frame size directly impacts your cycling efficiency. An XS frame is designed to cater to shorter riders, offering better balance and control. A well-fitted frame ensures that your energy is effectively transferred to the bike, enhancing speed and reducing fatigue over long rides. Riding an incorrectly sized bike can lead to discomfort and inefficient pedaling, making size selection vital.

2. Tips for Choosing the Right XS Frame:

Measure Your Inseam: Start by measuring your inseam to determine the correct standover height for the bike. This ensures you can comfortably mount and dismount the bike.

Consider Reach and Stack: Ensure the reach (distance from the saddle to the handlebars) and stack (height of the handlebars) are appropriate for your height. This affects your riding posture and comfort.

Test Ride: If possible, test ride different models to see which frame geometry feels most comfortable. Pay attention to how the bike handles and your ease of maneuverability.

Consult Experts: Seek advice from cycling experts or bike shop professionals who can provide personalized recommendations based on your body dimensions and riding style.

3. Impact on Comfort and Performance:

A properly fitted XS frame enhances comfort by reducing strain on your back and neck, allowing for better focus and endurance. It also improves performance by ensuring you can maintain an aerodynamic position, especially crucial for long-distance road cycling. An efficient ride means you can enjoy cycling longer and faster with less effort.

TRIFOXBIKE offers an impressive range of XS frame road bikes that cater to the needs of smaller riders. Their bikes are designed with precision, focusing on lightweight materials and advanced ergonomics to ensure maximum efficiency and comfort. To explore TRIFOXBIKE's selection of road bikes and find the perfect fit for an efficient ride, visit their product page: TRIFOXBIKE Road Bikes.

By choosing the right XS frame road bike, you can achieve a harmonious balance between speed, comfort, and performance, making your cycling experience both enjoyable and efficient.

Choosing the best carbon rim brake wheels is essential for cyclists aiming to elevate their performance. Carbon wheels offer numerous advantages that can significantly impact your ride, providing a balance of speed, control, and durability.

1. Advantages of Carbon Rim Brake Wheels:

Carbon wheels are prized for their lightweight properties, which enhance acceleration and climbing efficiency. The material's rigidity improves power transfer, ensuring that each pedal stroke propels you forward with minimal energy loss.

Additionally, carbon's aerodynamic capabilities reduce drag, allowing for faster speeds on flat terrains and descents. This combination of lightweight and aerodynamic features makes carbon wheels ideal for competitive racing and long-distance rides.

2. Factors to Consider:

When selecting carbon rim brake wheels, several factors should be considered:

Weight: Lighter wheels reduce the rotational mass, improving acceleration and making the bike more agile. This is crucial in races where quick speed changes are necessary.

Aerodynamics: Look for wheels with deep-section rims to reduce air resistance. This feature is particularly beneficial for time trials and flat courses.

Braking Performance: Ensure the carbon wheels come with a high-quality braking surface. This is essential for rim brake systems to provide consistent stopping power, especially in wet conditions. Some carbon wheels feature textured braking surfaces to enhance grip.

Durability: Carbon wheels should be robust enough to withstand the rigors of road cycling. Choose wheels that have been tested for impact resistance to ensure longevity.

3. Enhancing Cycling Performance:

Carbon rim brake wheels can transform your cycling experience by providing a smoother, faster, and more efficient ride. The reduction in weight allows for quicker accelerations, while the aerodynamic design helps maintain high speeds with less effort. This efficiency is vital for endurance rides, where conserving energy can make a significant difference.

TRIFOXBIKE's carbon road bike wheels exemplify these benefits. Designed with precision, they offer remarkable aerodynamics and lightweight characteristics tailored to enhance performance. Their wheels are crafted to ensure optimal power transfer and reliable braking, making them a superb choice for cyclists aiming to reach new heights in their performance.

To explore TRIFOXBIKE's carbon road bike wheels and discover how they can enhance your cycling performance, visit their product page: TRIFOXBIKE Carbon Road Bike Wheels. Investing in high-quality carbon wheels can provide the edge you need to surpass your personal bests and achieve superior cycling performance.

Selecting the right seatpost is a crucial yet often overlooked component in maximizing cycling efficiency. A seatpost not only supports your weight but also plays a significant role in the overall performance of your bike.

For those seeking to enhance their cycling efficiency, opting for a lightweight seatpost can make a noticeable difference in speed and comfort.

1. Importance of Seatpost Weight:

The weight of your seatpost is integral to the bike's overall weight, affecting acceleration, climbing, and handling. A lighter seatpost reduces the bike's weight, making it easier to handle and more responsive to pedaling inputs. This is particularly beneficial in competitive cycling where every gram counts.

2. Benefits of Carbon Seatposts:

Carbon fiber seatposts are the preferred choice for cyclists looking to shave off weight without compromising on strength. Carbon is renowned for its high strength-to-weight ratio, providing durability while being significantly lighter than aluminum or steel. Moreover, carbon seatposts offer enhanced vibration damping, leading to a smoother and more comfortable ride, especially on rough terrains.

3. Choosing the Right Seatpost:

When selecting a seatpost, consider your cycling style and needs. If weight savings are your top priority, a carbon seatpost is ideal. Ensure compatibility with your bike’s frame and saddle. The diameter and length of the seatpost must match your bike’s specifications to guarantee a secure fit and optimal performance.

For those seeking an excellent example of a lightweight carbon seatpost, the TRIFOXBIKE lightweight straight carbon MTB seatpost SLS21 stands out. It's designed with high-quality carbon fiber, offering substantial weight reduction while maintaining the strength required for mountain biking. This seatpost not only enhances climbing efficiency but also provides better control over technical terrains due to its lightweight nature.

4. Other Factors to Consider:

Beyond weight, factors such as adjustability and aesthetics might influence your choice. Some cyclists prefer seatposts with a setback for a more relaxed riding position, while others opt for a straight design for more aggressive riding. Ensure the seatpost aligns with your ergonomic needs and aesthetic preferences.

The TRIFOXBIKE SLS21 seatpost combines all the desired features, making it a sound investment for cyclists aiming to improve their ride. Its sleek design and superior performance characteristics make it a top choice for both amateur and professional cyclists.

To explore the TRIFOXBIKE lightweight straight carbon MTB seatpost SLS21 and see how it can enhance your cycling efficiency, visit their product page: TRIFOXBIKE Lightweight Straight Carbon MTB Seatpost SLS21. Embrace the advantages of a lightweight seatpost and elevate your ride to a new level of efficiency.