A great bike is more than the sum of its parts—it's an extension of your body. No matter how advanced your components, improper bike fit can lead to discomfort, inefficiency, and even injury. Achieving the right fit transforms your riding experience, maximizing both comfort and performance. This is especially crucial when you're investing in a precision-engineered racing frame like the Trifox X16QR, where every advantage of its lightweight frame design should work in harmony with your physiology.

The importance of proper bike fit begins with performance optimization. A well-fitted bike allows you to generate power efficiently through an optimal pedaling motion. When your saddle height, fore/aft position, and handlebar reach are dialed in, you engage the correct muscle groups, reduce energy waste, and maintain an aerodynamic position longer. This is where a quality lightweight frame truly shines—its stiffness and responsiveness translate your effort directly into speed, but only if your body is positioned to deliver that power effectively.

Comfort and injury prevention are equally critical. Poor fit is the leading cause of common cycling ailments: knee pain from incorrect saddle height, lower back strain from excessive reach, or hand numbness from improper weight distribution. A professional fit addresses these issues by aligning your joints and distributing pressure appropriately. The Trifox X16QR racing frame, with its multiple size options and modern geometry, provides the ideal starting point for achieving this balanced position.

Achieving your perfect fit involves several key measurements and adjustments:

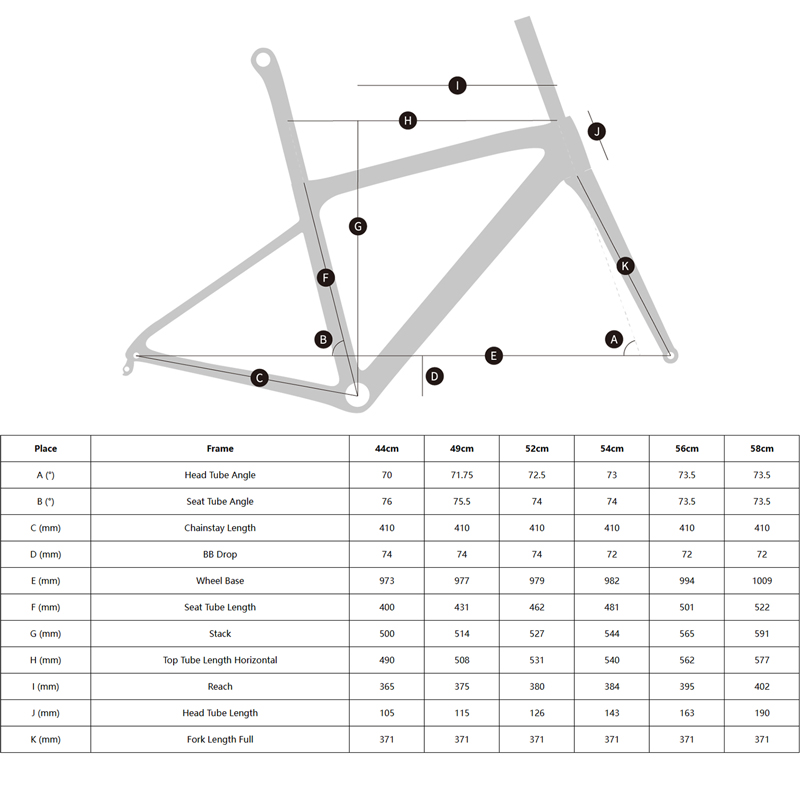

1. Frame Size Selection: This is your foundation. The Trifox X16QR comes in multiple sizes to accommodate different body proportions. Your ideal size is determined primarily by your inseam measurement and torso length, not just overall height. A frame that's too large forces excessive reach, while one too small leads to cramped positioning.

2. Saddle Position: Start by setting saddle height so your leg has a slight bend (25-35 degrees) at the bottom of the pedal stroke. Then adjust fore/aft position so your knee is directly above the pedal spindle when the crank is horizontal (the KOPS method). This ensures proper knee alignment and power transfer.

3. Handlebar Reach and Drop: Your handlebar position determines your upper body comfort. Reach (distance from saddle to bars) should allow a comfortable bend in your elbows without straining your back. Drop (height difference between saddle and bars) affects aerodynamics and back angle—more aggressive for racing, more relaxed for endurance.

4. Cleat Position: For riders using clipless pedals, cleat positioning on your shoes dramatically affects knee alignment and pedaling efficiency. Cleats should generally align with the ball of your foot, with slight adjustments based on your natural foot angle.

For the most accurate results, consider a professional bike fit. Many bike shops offer fitting services using motion capture technology, pressure mapping, and experienced fitters who understand biomechanics. While this represents an additional investment, it's often the most valuable upgrade you can make to your cycling experience.

When working with a high-performance frame like the X16QR, attention to component compatibility enhances your fit. The frame's geometry is designed for modern component standards, allowing precise adjustments through stem length, handlebar width, and crank arm length. Its carbon construction provides the stiffness needed for efficient power transfer while offering some compliance for long-ride comfort.

Ultimately, the perfect bike fit is personal and evolves with your fitness and riding goals. The Trifox X16QR provides an excellent platform with its multiple size options, modern geometry, and lightweight frame construction. By taking the time to dial in your position—whether through professional help or careful self-measurement—you'll unlock the full potential of your equipment. You'll ride faster, farther, and with greater enjoyment, proving that the right fit is where true performance begins.

Let's be honest: the sight of a modern internal cable handlebar can be intimidating. The sleek, unbroken lines promise aerodynamic gains and a clean look, but they also whisper of complicated installations and future maintenance headaches. These concerns are valid, but they're also largely based on outdated experiences. Today's integrated cockpits, like the Trifox RHB600, are designed with the user in mind, transforming installation from a daunting task into a straightforward, confidence-building process.

The key to success lies in understanding the systematic approach to installation. First and foremost: Torque and Tools Matter. This cannot be overstated. Carbon components require precise installation. For the RHB600 carbon mtb bar, we specify exact torque values for the stem faceplate bolts (typically 4-6 Nm) and the top cap pre-load bolt (typically 2-4 Nm). Using a quality torque wrench is not optional; it's essential to prevent slipping, overtightening, and potential damage. Always apply a thin layer of carbon assembly paste to the handlebar clamp area and the steerer tube to ensure a secure, non-slip interface. This simple step ensures your position stays put without damaging the carbon fibers.

The Bolt Layout Design of the stem section is engineered for ease and security. The RHB600 features a 4-bolt front-loading faceplate. This design allows you to easily place the handlebar, set your desired angle, and then evenly tighten the bolts in a cross pattern. This method ensures uniform pressure distribution, eliminating gaps or uneven clamping force that could lead to stress points or slippage. The included top cap and spacers provide the necessary flexibility to fine-tune your stack height before finalizing the headset preload, making initial setup intuitive.

Now, let's tackle the elephant in the room: Integrated Routing Simplified. The RHB600 is designed to make cable and hose installation as painless as possible. Key features facilitate this:

* Large, Accessible Ports: The entry and exit ports are generously sized, making initial threading much easier.

* Smooth Internal Channels: The interior of the carbon bar is molded with smooth guides to prevent hoses from snagging.

* Removable Port Covers: The sleek rubber grommets or port covers can be easily removed for routing and just as easily popped back in for a clean finish.

Think of it this way: We've done the hard part. The complex internal channels are precision-molded into the carbon structure during manufacturing. Your task is simply to guide the cables and hoses through a pre-designed, optimized path. Start by feeding a mechanic's cable or a dedicated guide wire through from the stem end, attach your housing, and pull it through. A little patience and the right technique make the process manageable for any home mechanic.

This focus on user-friendly design extends from installation to long-term Serviceability. The fully integrated design isn't a maintenance trap. Once set up, the system is incredibly reliable. Should you ever need to replace a cable or hose, the process is simply the initial installation in reverse. The design ensures that routine maintenance remains accessible.

Ultimately, the RHB600's installation process is a direct reflection of a user-centric design philosophy. By providing clear guidelines, thoughtful engineering in the bolt layout, and simplifying the internal routing path, we've turned a potential barrier into an opportunity. Following these steps doesn't just secure your components; it builds your confidence in the product. A proper installation is the first step in building trust with your new carbon mtb bar, transforming initial apprehension into the satisfying certainty of a secure, professional-grade setup that's ready for the trail.

Choosing a carbon mountain bike is about matching technology to terrain. Not all trails demand the same bike, and understanding this relationship helps you select the perfect companion for your riding style. While enduro and downhill bikes dominate technical descents, there's a sweet spot for riders who prioritize efficiency, climbing capability, and playful handling on varied singletrack. This is where thoughtful design—like the Trifox Pioneer 29er full suspension bike—truly shines.

For cross-country (XC) enthusiasts and trail riders, the primary considerations differ significantly from enduro or downhill priorities. Weight becomes a crucial factor when you're spending hours climbing and covering long distances. A true lightweight full suspension mountain bike like the Pioneer offers the perfect balance: enough suspension to smooth out trail chatter and handle moderate obstacles while remaining efficient on climbs and flats. Carbon fiber construction is key here, providing the stiffness-to-weight ratio that aluminum can't match, ensuring every pedal stroke translates to forward motion.

The Pioneer's suspension design represents what many riders seek in a modern soft tail mountain bike—enough travel to enhance control and comfort without compromising pedaling efficiency. With its 120mm front and rear travel, it's specifically tuned for trail and XC use, absorbing small to medium impacts while maintaining excellent power transfer. This "just right" approach means you're not carrying unnecessary suspension weight or geometry compromises for terrain you rarely encounter.

Geometry plays a pivotal role in trail experience. The Pioneer features modern trail geometry that's more progressive than traditional XC bikes but more nimble than enduro rigs. A moderately slack head angle provides stability on descents without sacrificing climbing prowess. The chainstay length and bottom bracket height create a balanced feel that encourages playful handling on twisty singletrack while remaining stable at speed. This careful calibration makes it adaptable to everything from flowing forest trails to technical rock gardens.

Component selection further defines the bike's character. Equipped with a Shimano R6100 groupset, the Pioneer delivers reliable, precise shifting across a wide gear range—essential for varied terrain where quick shifts maintain momentum. Quality suspension components complement the carbon frame's capabilities, ensuring the bike handles predictably. The complete package demonstrates how thoughtful specification creates a bike greater than the sum of its parts.

What makes the Pioneer particularly compelling is its all-around capability. It's neither an ultra-lightweight race machine nor a heavy-duty bruiser. Instead, it occupies the versatile middle ground where most trail riders actually spend their time. It climbs efficiently, descends confidently, and handles technical features competently. For riders who enjoy varied terrain rather than specializing in extreme downhill or pure racing, this versatility is exactly what's needed.

Ultimately, selecting the right carbon mountain bike comes down to honest assessment of your riding style and local trails. If your rides mix climbing with descending, value efficiency alongside capability, and prioritize fun over specialization, a balanced lightweight full suspension mountain bike like the Trifox Pioneer offers exactly what you need. It proves that the best bike isn't necessarily the one with the most travel or lightest weight, but the one that enhances your specific trail experiences most consistently.

In the pursuit of mountain bike performance, riders often focus on marginal gains—especially weight savings. But what if the most significant upgrade isn't about shaving grams from your wheels, but about transforming the very foundation of your ride? Starting with a carbon frame and proven alloy wheels isn't a compromise; it's a strategic decision that prioritizes ride quality, durability, and real-world value.

The carbon frame is the heart of your bike's performance. A frame like the Trifox MFM200 29 inch hardtail frame delivers immediate and tangible benefits: exceptional stiffness for efficient power transfer, advanced geometry for confident handling, and carbon's natural vibration damping for reduced fatigue. These characteristics fundamentally change how the bike responds to your input and interacts with the trail. For most off-road riding, the improvements in pedaling efficiency, control, and comfort from a well-designed carbon frame far outweigh the marginal gains from ultra-lightweight wheels.

Right now, this performance-optimized combination is incredibly accessible. The Trifox MFM200 carbon hardtail frame paired with a durable WM823 alloy wheelset is available as a complete bundle for just $342 USD with free shipping. Available in multiple colors, this offer makes entering the world of carbon performance more attainable than ever.

Alloy wheels bring their own set of proven advantages that perfectly complement a carbon frame's performance:

Durability and Strength: Aluminum rims are exceptionally resilient against impacts from rocks, roots, and trail debris. They can take the punishment of aggressive trail riding without the anxiety of damaging expensive carbon rims. This durability lets you ride harder and focus on the trail, not on protecting your equipment.

Maintenance Simplicity: Alloy wheels are easier to maintain and repair. Truing, replacing spokes, and addressing dings are straightforward processes for any bike shop. For disc brake setups, alloy rims also eliminate concerns about heat-related brake performance issues that can affect some carbon rims on long descents.

Budget Allocation Wisdom: By choosing a carbon frame with alloy wheels, you allocate your budget where it makes the most difference. The savings can be invested in other critical components like a better suspension fork, upgraded drivetrain, or personalized cockpit setup—creating a more balanced, capable bike overall.

This combination creates a powerful synergy. The carbon frame provides the efficient, responsive platform, while the alloy wheels deliver reliable, durable performance. The frame's advanced engineering isn't wasted; it's fully expressed through wheels that can handle whatever the trail throws at them. For riders seeking a 29er mountain bike small frame, this approach ensures proportional handling and fit without sacrificing performance or durability.

Ultimately, this pairing is ideal for the practical performance rider: someone who logs serious miles, tackles technical terrain, and values reliability alongside performance. It's not about chasing the lightest possible build; it's about creating a bike that performs consistently, handles confidently, and withstands real-world use. The carbon frame and alloy wheels combination represents intelligent engineering meeting practical wisdom—delivering exceptional ride quality without unnecessary fragility or expense.

With the Trifox MFM200 frame and WM823 wheelset bundle, you're not just buying components; you're investing in a balanced approach to mountain bike performance. Experience how the right foundation transforms every ride, and discover why sometimes the smartest upgrade path is also the most practical one.

At Trifox, we believe that confidence in your equipment is fundamental to riding performance. This is especially true for components like handlebars that directly impact both control and safety. Our carbon integrated handlebars undergo some of the most rigorous testing in the industry, culminating in destructive failure tests that push materials far beyond normal use limits. Here's an inside look at how we ensure every bar, like our Carbon Integrated Handlebar RHB100, meets our exacting standards.

The journey to failure begins long before the actual break. We start with raw material validation, ensuring the carbon fiber weave and resin matrix meet precise specifications for strength, stiffness, and weight. Each batch of material is tested for consistency, because superior components start with superior ingredients.

Once a handlebar like the Trifox RHB100 is molded and finished, it enters our mechanical testing lab. The most critical test is the static load test to destruction. The bar is mounted in a fixture that simulates a bicycle stem clamp. We then apply increasing force to the drops, the hoods, and the center section independently, measuring deflection until the point of catastrophic failure. This data tells us not just the ultimate strength, but also the bar's stiffness profile and how it behaves under extreme stress. For an aero handlebars design, we also test for torsional rigidity, ensuring the aerodynamic shape doesn't compromise handling precision.

Beyond static force, we perform fatigue testing. Here, we subject the handlebar to thousands of cycles of repetitive, lower-level stress—simulating years of rough terrain, sprinting, and out-of-saddle climbing. This test is crucial for uncovering potential weaknesses that might not appear in a one-time strength test. It proves the component's durability and longevity, a key factor for riders considering the best mountain bike riser handlebars for aggressive trail use.

Why do we deliberately destroy our products? Because safe design requires knowing the exact boundaries. By understanding how and when a bar fails, we can engineer it to be massively strong in real-world conditions. The failure point in our tests is typically 3-5 times higher than the maximum forces a rider could ever generate, creating a huge safety margin. This process validates our finite element analysis (FEA) models, allowing us to optimize material placement. We can add strength where it's needed (like at the clamp and lever areas) and reduce weight where it's not, achieving the perfect balance.

The Trifox RHB100 Carbon Integrated Handlebar is a product of this philosophy. Its one-piece monocoque construction eliminates weak points from bonding. The aero-profile top section is designed not just for speed, but also for optimal stiffness and vibration damping. The testing regimen ensures that whether you're seeking aero handlebars for road racing or robust best mountain bike riser handlebars for technical descents, the underlying principle is the same: unshakeable reliability.

This commitment to empirical validation means when you choose a Trifox handlebar, you're not just choosing a lightweight or aerodynamic component. You're choosing a piece of equipment with a verified performance envelope, engineered to inspire confidence on every ride. We don't just build handlebars; we build trust, one destructive test at a time.

In mountain biking, a dropper post is more than a component; it's an extension of your body, a dynamic tool for reshaping the bike beneath you. While travel length gets the headlines, the true soul of a high-performance dropper lies in two intangible qualities: control and speed. Not just how fast it moves, but the confidence, precision, and consistency of that movement. A post that stutters, lags, or requires a second thought breaks your flow. A truly great post, like the Trifox AP309, disappears into the ride, becoming an instinctive lever for control that directly translates to more speed.

The Anatomy of Perfect Control: Frictionless and Instinctive

Control begins the moment your thumb touches the remote. It should feel like an extension of your will.

The Remote: Your Direct Link

The ergonomics and leverage of the remote are critical. The AP309 features a responsive remote lever designed for single-finger operation. The action is engineered to be smooth, requiring a consistent, manageable force—not a hard punch or a vague mush. This precise mechanical feel gives you subconscious confidence that the command has been received, allowing you to focus entirely on the trail ahead.

Versatile Cable Routing for Reliability

A key aspect of reliable control is how the command is transmitted. The AP309 offers versatile routing to suit any frame and preference:

External Routing (Top/Mid): The classic, simplest setup. The cable is routed externally along the frame, offering the easiest installation, maintenance, and most direct cable pull for consistent lever feel. This is the go-to choice for maximum reliability and simplicity.

Internal Routing (Full): For a clean, streamlined look, the cable can be routed internally through the frame. This protects the cable from debris and snags, maintaining a clean aesthetic.

This flexibility ensures you can achieve optimal cable routing on any bike, eliminating sharp bends or friction points that can compromise the smooth "press-and-drop" feel.

The Power of Adjustable Speed: Tailoring Your Descent

Speed isn't just about being fast; it's about being appropriately fast. This is where adjustability becomes a game-changer.

Why Speed Matters: A post that drops too slowly can leave you awkwardly waiting in a technical section. One that snaps up too quickly can be jarring or even unsafe on a climb transition. The ability to fine-tune both the drop speed and return speed allows you to match the post's behavior to your riding style and the trail's demands.

The AP309's Approach: The Trifox AP309 features a user-friendly speed adjustment system. Through a simple dial, you can independently control the post's return speed. Want a lightning-fast drop for quick, repeated features? Dial it for a quick return. Prefer a slightly more controlled, damped rise for smooth XC pedaling transitions? You can set that too. This customization makes the post an active part of your technique, not just a passive tool.

Reliability: The Foundation of Trust

All the control and speed in the world mean nothing without unwavering reliability. A post must work flawlessly, ride after ride.

Robust Construction & Sealed Design: The AP309's 30.9mm diameter provides a solid, torsion-resistant platform. Its core utilizes a reliable air spring system, known for its consistent performance across its 125mm of travel. Crucially, it's equipped with effective dust and moisture seals that protect the sensitive internal mechanism from trail grime, preventing the friction and stickiness that lead to failure.

Consistent Performance Under Load: A true test of a dropper is its performance when the bike is sideways or under lateral load. The AP309's internal valve system is designed to provide consistent, reliable actuation regardless of bike angle, ensuring you get that critical saddle drop even when you need it most in a steep, off-camber section.

The Trifox AP309: Engineered for the Experience

The Trifox AP309 Dropper Post embodies the principles of control and speed. It's not just a lightweight dropper post (a benefit of its efficient air-spring design); it's a thoughtfully engineered control interface. As a versatile 30.9mm external dropper post with multiple routing options, it prioritizes reliable cable actuation above all. By combining this with adjustable action and a robust, sealed build, the AP309 is built to become an invisible, yet indispensable, part of your riding—transforming your bike into a dynamic partner that actively helps you ride faster, smoother, and with more confidence.

Conclusion: The Invisible Advantage

The ultimate compliment for a dropper post is that you forget it's there. You don't think about the cable routing or the mechanics; you simply use it. Your body learns it, trusts it, and incorporates its movement into your flow. When control is immediate, speed is tunable, and reliability is absolute, the post stops being a piece of equipment and starts being a part of your skillset. It is the key to unlocking a more fluid, confident, and ultimately faster ride. Choose a post defined by control and speed, and feel the difference on every trail.

Unlocking the full potential of a modern cross country full suspension bike is an art. A frame like the Trifox Trail II Pro offers a lightweight, stiff carbon platform designed for efficiency, but its rear shock needs precise tuning to match. A poorly tuned shock can make even the best double suspension mtb feel harsh or wallowy. This guide will help you sync your shock with your frame's personality for a ride that’s both fast and forgiving.

Step 1: Foundation – Setting Sag and Leverage Rate

Every setup begins with sag—the amount your shock compresses under your weight in a neutral riding position. For an XC-focused frame, aim for 20-25% sag. This balances pedaling efficiency with bump absorption.

Why it matters for carbon frames: Carbon’s high stiffness translates pedal input directly. Correct sag ensures the suspension is in its optimal part of the stroke to react to trails without wasting energy.

Pro Tip: Know your frame's leverage ratio. The Trail II Pro is designed with a specific progressive or linear curve. Check the manufacturer's guide; this tells you how the shock feels through its travel. A progressive frame (common in modern designs) helps prevent bottoming out on big hits.

Step 2: Controlling the Motion – Rebound Damping

Rebound damping controls how quickly the shock returns after compression. This is crucial for maintaining traction.

Too Fast: The bike feels springy and can "kick back," losing tire contact.

Too Slow: The shock "packs down" over successive bumps, feeling harsh and reducing travel.

Setting Rebound:

1. Set sag correctly first.

2. Find a bumpy trail or series of curb drops.

3. Start with rebound fully open (fast). Ride and gradually add clicks (slow it down).

The Goal: The rear wheel should recover quickly enough to handle the next bump but not so fast it causes the bike to bounce. The rear should feel "calm" and controlled.

Step 3: Refining the Feel – Compression Damping

Compression damping controls how the shock compresses under force. Most XC shocks have low-speed compression (LSC) for pedaling/platform support.

LSC Tuning: Start with LSC fully open. On a smooth climb or while pedaling hard on flat ground, add clicks until you feel a noticeable reduction in unwanted bob without making the ride feel harsh over small bumps. The goal is a firm, efficient platform that still remains active.

The Critical Link: Frame Bushing & Bearing Care

Your tuning is only as good as the mechanical connection between the shock and frame. Friction from dry or worn pivots destroys sensitivity.

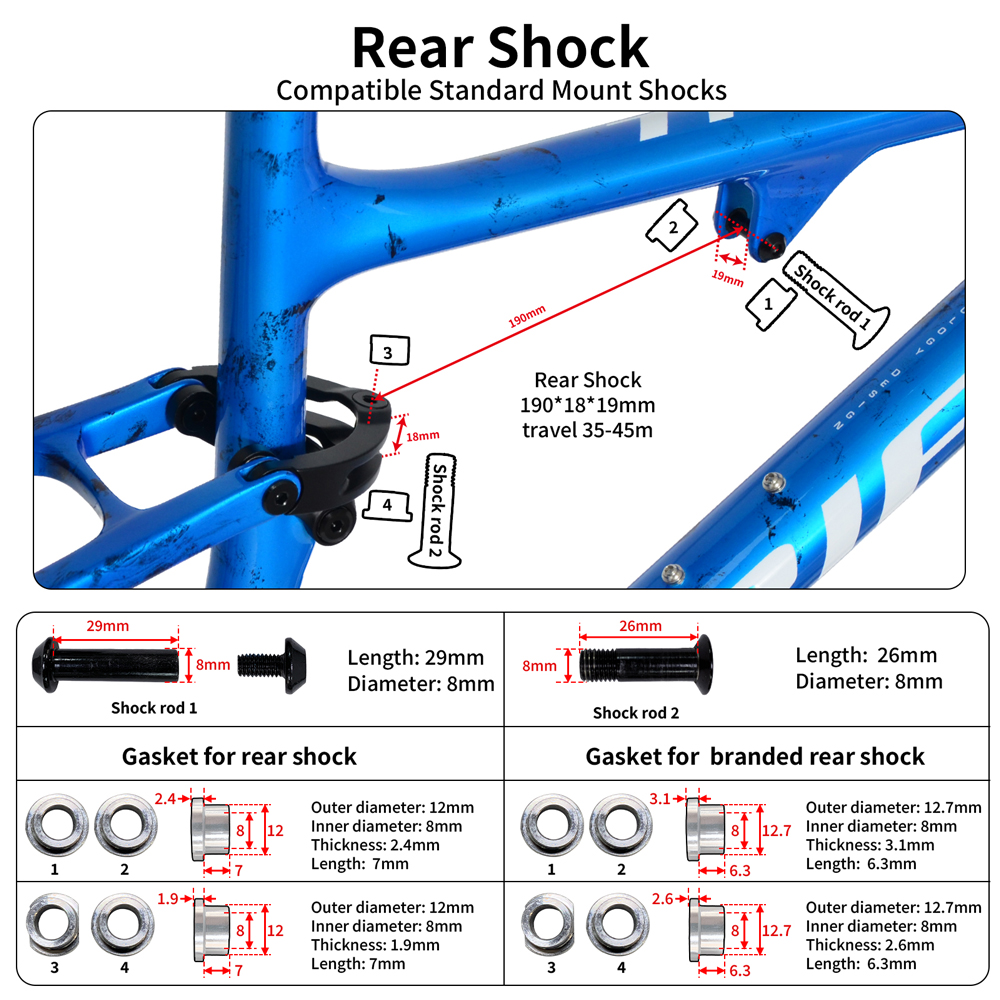

The Trifox Advantage: The Trail II Pro includes a set of premium 190x18mm and 190x19mm replacement bushings, compatible with major shocks from Fox and RockShox. This ensures you always have a perfect-fit, low-friction interface on hand.

Maintenance: Regularly check pivot bolts for proper torque (use a torque wrench!). Annually, or if play develops, inspect bushings and bearings for wear. A well-lubricated, slop-free pivot system allows your finely tuned shock to perform exactly as intended, translating every damping click into a tangible trail feel.

Final Tune: Match Shock to Frame Intent

Understand your frame's design goal. The Trail II Pro is a lightweight XC race machine. Prioritize a setup that favors:

Efficient climbing (firmer LSC, proper sag).

Traction and control on technical, rocky ascents (balanced rebound).

Confidence on descents (enough progression and damping to handle drops).

Don't be afraid to make small adjustments and test. Terrain changes, and so should your setup. Start with manufacturer base recommendations, then use this guide to personalize. When your shock’s dynamics are in harmony with your carbon frame's stiffness and geometry, you’ll experience the true synergy of a modern cross country full suspension bike—where every watt of effort propels you forward, and every trail feature is an opportunity, not an obstacle.

In the competitive world of road cycling, weight, performance, and value often exist in a delicate balance. The Trifox X16TA Disc Brake Lightweight Carbon Road Bike Frame disrupts this equation by offering exceptional quality at an accessible price point. With impressive weight specifications, comprehensive sizing, and modern features, this frame has garnered attention from builders seeking professional-level performance without the premium price tag.

Impressive Weight Savings: From Frame to Complete Build

The weight specifications of the X16TA immediately stand out. At just 971g ± 30g for the popular 44cm size, this lightweight bike frame demonstrates what modern carbon manufacturing can achieve. Documented builds using this frame have achieved complete 7kg road bike weights—an impressive feat that places these builds in the same weight category as bikes costing significantly more. This lightweight characteristic doesn't come at the expense of durability, with the carbon fiber layup providing optimal stiffness for power transfer while maintaining sufficient compliance for rider comfort.

Geometry Optimized for Performance Riding

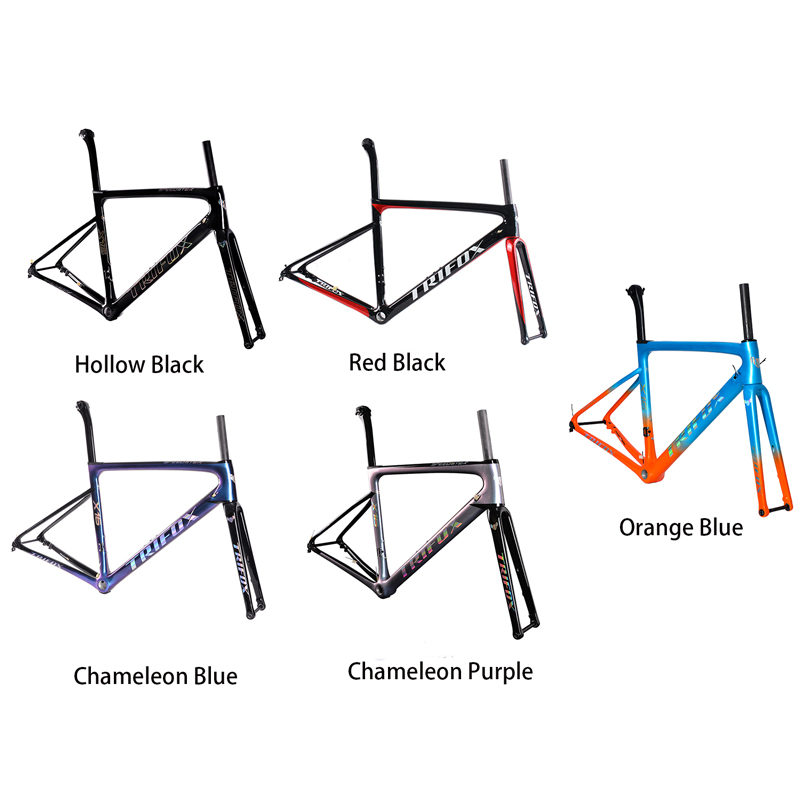

The X16TA features geometry designed for performance-oriented riding rather than endurance-focused comfort. The carefully calculated angles and tube lengths create a balanced position that's aggressive enough for fast group rides and racing while remaining manageable for most fit riders. This is a true racing bike frame designed for riders who want a responsive, race-ready platform, with comprehensive sizing ensuring most riders can find their perfect fit.

Aesthetic Appeal & Technical Specifications

Visual design plays a significant role, and the X16TA offers appealing options including the previously popular color-shifting blue and the new blue-orange color scheme. The frame features semi-internal routing that keeps the cockpit tidy while maintaining accessibility for maintenance. The frame accommodates tires up to 700C x 28mm and supports both electronic (including Shimano Di2) and mechanical groupsets, offering builders maximum flexibility in component selection.

Complete Package & Riding Experience

Unlike many frames sold separately, the X16TA typically comes as a complete road bike frameset including frame, fork, and seatpost. This comprehensive offering represents significant value, as these components are carefully matched to work together optimally. On the road, the X16TA delivers the responsive, lively feel that performance-oriented riders seek, with the disc brake road frame compatibility enhancing the riding experience with consistent, powerful braking in all conditions.

Value Proposition: Performance Within Reach

Perhaps the most compelling aspect of the X16TA is its value proposition as an affordable carbon frame. By offering a lightweight, well-designed carbon frame with modern features at an accessible price point, it opens high-performance road cycling to more enthusiasts. For riders who want to allocate more of their budget toward high-quality components rather than an expensive frame, the X16TA represents an intelligent choice that provides a solid foundation without compromising essential performance characteristics.

Conclusion: A Strong Contender in the Value Segment

The Trifox X16TA Carbon Frame successfully addresses multiple needs for performance-oriented cyclists. Its light weight, comprehensive sizing, attractive color options, and thoughtful technical specifications combine to create a compelling package. For builders seeking a high-quality carbon foundation without the premium price tag, or for riders wanting to experience the benefits of modern carbon frame technology, the X16TA represents an excellent performance road frame option that makes high-quality road cycling more accessible to dedicated enthusiasts.

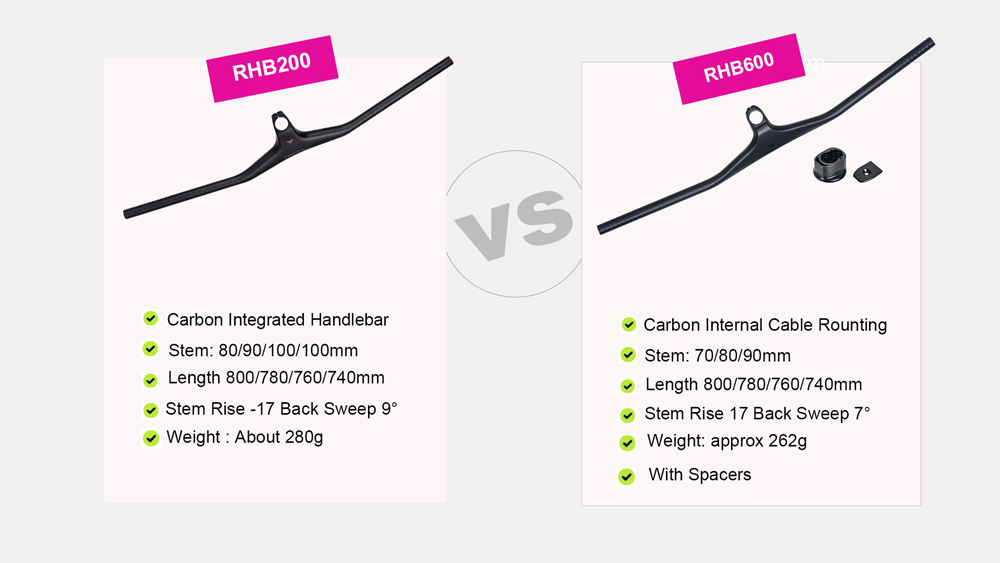

In the quest for a cleaner cockpit and enhanced performance, integrated handlebars have become the upgrade of choice for discerning mountain bikers. Trifox offers two excellent options in this category: the RHB200 and RHB600. Both are carbon fiber integrated MTB handlebars designed to improve your bike's front end, but they feature key differences that cater to varying preferences and needs. Understanding these distinctions will help you select the perfect cockpit upgrade for your trail adventures.

Design & Construction: Carbon Excellence for Mountain Biking

Both the Trifox RHB200 and RHB600 utilize high-quality carbon fiber construction, offering the ideal balance of lightweight performance and trail-ready durability. As carbon mtb handlebars, they provide superior vibration damping compared to aluminum alternatives, reducing hand fatigue on long rides while maintaining the stiffness needed for precise control in technical sections.

Geometry & Fit: Tailored for Trail Performance

Both handlebars are designed specifically as mountain bike riser handlebars with ergonomic geometries optimized for off-road riding. They feature moderate rise (typically 20-35mm) and backsweep (8-9 degrees) that position your hands naturally for control and comfort during long trail sessions. Both models represent excellent choices for riders seeking responsive mtb bicycle handlebars.

Cable Management: The Defining Difference

This is where the two models diverge most significantly, representing different approaches to cockpit cleanliness and maintenance accessibility.

The RHB200 Carbon Integrated MTB Handlebar utilizes a semi-integrated routing approach. While it features clean entry and exit points for cables, some cable housing may remain partially visible along the bar and stem interface. This design offers easier installation and maintenance while still providing a cleaner look than traditional separate components.

The RHB600 Carbon Integrated Full Internal MTB Handlebar represents the pinnacle of cockpit integration. All brake lines, derailleur cables, and dropper post housings route completely internally through the bar and stem structure. This full internal routing creates an exceptionally clean appearance while protecting cables from trail debris and weather elements. This makes the RHB600 a superior choice for those seeking the ultimate in internal cable routing solutions.

Weight & Performance Considerations

As lightweight mtb cockpit solutions, both bars offer significant weight savings over traditional setups. The RHB200 typically weighs between 260-300g (depending on width), making it a noticeable upgrade for riders seeking to reduce front-end weight without compromising strength.

The RHB600, with its additional material for internal routing channels, still very light (approximately 240-290g) and represents a significant improvement over non-integrated alternatives. Both models provide the responsive handling characteristics that serious mountain bikers demand from their mtb bars.

Compatibility & Installation

Both Trifox handlebars are designed for modern mountain bikes with tapered steerer tubes. The integrated stem lengths vary between models and within each product line to accommodate different bike geometries and rider preferences.

The RHB200 offers relatively straightforward installation similar to traditional handlebars, making it accessible for most home mechanics. The RHB600 requires more careful installation due to its internal routing system but rewards users with the cleanest possible cockpit aesthetic.

Value Proposition: Which Bar Is Right for You?

The choice between these two excellent carbon mtb handlebars comes down to your priorities for aesthetics, maintenance preferences, and budget.

Choose the Trifox RHB200 if you want a significant cockpit upgrade at a more accessible price point, value easier installation and maintenance, appreciate cleaner aesthetics but don't require complete cable concealment, or are building or upgrading a trail bike where value and performance balance matters.

Choose the Trifox RHB600 if you demand the cleanest possible cockpit appearance with full cable integration, prioritize modern, sleek aesthetics, don't mind the additional complexity of internal routing installation, or are creating a high-end build where every detail contributes to the overall premium appearance.

Both the RHB200 and RHB600 deliver exceptional value in their respective categories, offering the performance benefits of carbon fiber construction with improved integration over traditional setups. Whether you choose the accessibility of the RHB200 or the ultimate integration of the RHB600, you'll be upgrading to a cockpit that enhances both the performance and appearance of your mountain bike.