Remember when carbon fiber was reserved for pro pelotons and deep-pocketed racers? Not anymore. Mountain biking is witnessing the unstoppable rise of carbon, transforming trails from XC loops to gnarly enduro descents. Brands like Trifox are making this once-exotic material accessible, proving carbon MTBs aren't just lighter – they're better riding machines. Here's why the shift is seismic:

Featherweight Flight: This is the headline. Carbon frames slash pounds off alloy counterparts. Less weight means easier climbing, quicker acceleration, and less fatigue over long days. You carry the bike less; the bike carries you more. Trifox's carbon hardtails and full-suspension rigs exemplify this advantage, turning arduous ascents into achievable efforts.

Stiffness Meets Sensation: Carbon isn't just light; it's incredibly tuneable. Engineers craft frames with targeted stiffness where it matters most: the bottom bracket for efficient pedaling, the head tube for precise steering. Yet, carbon's magic lies in its ability to also offer vertical compliance. It absorbs smaller trail chatter better than alloy, reducing arm and leg fatigue, letting you ride harder, longer.

Strength You Can Trust: Forget the "fragile" myth. Modern carbon layups create structures incredibly resistant to impacts and fatigue. When designed correctly (like Trifox's robust mountain frames), carbon handles rock strikes, drops, and rough terrain with impressive resilience. It won't dent like aluminum and shrugs off corrosion.

Ride Refined: The combination of lightness, stiffness, and subtle flex translates to a more connected, responsive, and lively feel. You feel the trail without being beaten by it. Carbon bikes track better through corners, feel more nimble in the air, and offer a directness that boosts confidence when pushing limits.

Trifox: Bringing Carbon to the Trail

Brands like Trifox are crucial to this rise. By leveraging efficient manufacturing and direct-to-consumer models, they deliver high-performance carbon mountain bikes at astonishingly competitive prices. Whether it's their agile carbon hardtails perfect for XC and trail blasting, or their capable full-suspension platforms, Trifox proves you don't need a pro contract to experience the carbon revolution.

The Verdict: Not Just a Trend, The Future

The rise of carbon fiber in mountain biking isn't just hype; it's a fundamental shift driven by tangible performance benefits. It offers a superior blend of weight, strength, stiffness, and ride quality that alloy struggles to match. As manufacturing advances and brands like Trifox make it more accessible, carbon is becoming the material of choice for riders seeking every advantage on the trail. It’s not about replacing alloy entirely, but about offering a compelling, high-performance option that’s redefining what’s possible on two wheels. Ready to feel the difference? Explore the carbon evolution: Discover Trifox Mountain Bikes.

That stock saddle on your road bike? It served its purpose getting you started. But if you're chasing performance, comfort, or simply a more refined ride, upgrading to a full-carbon saddle like the Trifox CS200 is a game-changer. Forget the misconception that carbon is harsh – modern designs blend featherweight efficiency with surprising comfort. Here's why the switch is worth it:

1. The Weight Weenie Wins: This is the obvious one. At a claimed 120 grams, the Trifox CS200 utterly demolishes typical alloy-railed saddles (often 250g+). Shedding 100+ grams directly off your bike, especially high up and at the contact points, makes a tangible difference. It's pure acceleration, easier climbing, and the satisfaction of marginal gains realized. Every watt feels more efficient.

2. Stiffness = Power Transfer: Carbon fiber's inherent stiffness isn't just for weight savings. It means virtually zero flex under power. When you stomp on the pedals, every ounce of energy goes into propelling you forward, not lost compressing padding or flexing the shell. You'll feel a more direct, connected drive, especially during sprints and out-of-the-saddle efforts.

3. Engineered Comfort (Yes, Really!): "Carbon must be hard!" is the biggest myth. Saddles like the CS200 use carefully sculpted shapes, strategic flex zones in the carbon base, and minimal high-density padding precisely where needed. This provides targeted support to your sit bones, reducing pressure on soft tissue. Less padding can actually mean less numbness on long rides, as your weight is correctly distributed. The shape is key, and many find carbon shells conform better over time.

4. Breathability Matters: Ever finished a long ride feeling swampy? Full-carbon bases are inherently perforated or designed with significant cutouts/channels (like the CS200). This promotes airflow, drastically reducing heat and moisture buildup. Enhanced ventilation equals greater comfort and reduced friction, ride after ride.

5. Durability & Low Maintenance: Carbon fiber is incredibly resilient to fatigue and corrosion. Unlike leather or synthetic covers that can degrade, or rails that can rust, a quality carbon saddle shrugs off sweat, weather, and miles. It requires minimal upkeep beyond wiping clean.

The Trifox CS200: A Prime Example

The Trifox CS200 exemplifies these benefits perfectly:

- Ultralight 120g: Significant weight savings.

- Full Carbon Shell & Rails: Maximizes stiffness and durability while minimizing weight.

- Strategic Padding: Minimal, high-rebound foam for targeted comfort without bulk.

- Central Cutout: Enhances breathability and relieves perineal pressure.

- Aerodynamic Shape: Sleek design complements a performance road bike.

Is it for Everyone?

Like any saddle, fit is paramount. A carbon saddle's shape needs to match your anatomy. If the stock shape works for you, upgrading to carbon refines it. If not, focus on finding the right shape first, then consider carbon for the performance benefits. The Trifox CS200 offers a popular, performance-oriented profile.

The Upgrade Verdict:

Upgrading to a carbon saddle isn't just about shaving grams; it's about enhancing the fundamental connection between you and your bike. The blend of dramatic weight reduction, efficient power transfer, surprising comfort through intelligent design, and superior breathability creates a noticeably better riding experience. If you're ready to feel more connected, efficient, and comfortable, especially on demanding rides, a saddle like the Trifox CS200 is a worthy investment. It transforms a crucial contact point from a necessary component into a performance asset. Make the switch and feel the difference!

Forget "just" improved stopping power – switching to a dedicated disc brake wheelset unlocks a cascade of performance benefits that fundamentally elevate your road riding. It's not an incremental upgrade; it's a transformation in control, confidence, and capability.

Why Disc Wheelsets Rule the Road:

1. Unshakeable Confidence, Anywhere, Anytime: Rim brakes falter in wet grit or on long, steep descents. Discs deliver consistent, powerful, and modulated braking performance regardless of weather, road grime, or gradient. This translates directly to riding faster with more control when it matters most.

2. Aerodynamic & Structural Advantages: Free from the need for a braking surface, disc wheelsets allow for wider, deeper, and more aerodynamically optimized rim profiles. This reduces drag for free speed. The rim itself is also stronger without the wear surface, enabling lighter constructions and improved impact resistance.

3. Tubeless Paradise: Disc wheelsets are the perfect partners for tubeless tires. Wider rims create a better tire profile for lower rolling resistance, enhanced grip, and the holy grail: fewer flats at lower pressures. No more worrying about brake track wear from heat during hard descents either.

4. Future-Proof Performance: The industry standard is clear. Disc brakes dominate new road bikes. Investing in a quality disc wheelset ensures compatibility with the latest frames and groupsets, protecting your upgrade path.

The Trifox WT11: Performance Engineered for Disc:

The WT11 Disc Brake Centerlock Clincher Carbon Wheelset embodies these advantages:

- Lightweight Carbon Construction: Prioritizes acceleration and climbing response.

- Optimized Aero Depth: Balances speed and crosswind stability.

- Wider Rim Profile: Enhances tire performance and supports tubeless setups seamlessly (valves included!).

- Reliable Centerlock Interface: Ensures secure rotor mounting and easier maintenance.

- Stiffness & Durability: Engineered for powerful sprints and demanding riding.

Who Wins with Disc Wheels?

- All-Weather Warriors: Ride confidently rain or shine.

- Descenders & Climbers: Brake later, descend faster, climb without rim heat worries.

- Speed Seekers: Leverage superior aero and tubeless efficiency.

- Tech Adopters: Invest in the modern standard.

Ready for Uncompromised Control & Speed?

Upgrade your stopping power, unlock aerodynamic gains, embrace tubeless simplicity, and future-proof your ride. Disc wheelsets aren't just better brakes; they're the foundation for a faster, safer, and more enjoyable road experience.

In an era of complex full-suspension rigs, the aluminium hardtail mountain bike holds a special, enduring appeal. It’s not about nostalgia; it’s about a distinct, exhilarating riding experience defined by purity, efficiency, and a direct connection to the trail that modern aluminium frames elevate perfectly.

Why Choose the Aluminium Hardtail?

- Unbeatable Efficiency: Every watt of your pedal power translates directly into forward motion. Aluminium frames offer fantastic stiffness, ensuring minimal energy loss. You feel faster, especially on climbs and flowing singletrack where acceleration is key.

- Trail Telepathy: Without rear suspension, you feel every root, rock, and contour. This direct feedback sharpens your skills, improves your line choice, and creates an incredibly immersive, connected ride. You learn to flow with the trail, not just float over it.

- Lively & Playful: Modern aluminium frames are surprisingly compliant, offering a lively, responsive feel. The hardtail design encourages popping off features, manualing, and flicking the bike around with agility – pure, unadulterated fun.

- Robust & Reliable: Aluminium is tough. It shrugs off rock strikes and minor crashes. Combine that with the inherent simplicity of a hardtail (fewer pivots, less maintenance), and you have a bike built for relentless trail duty and adventure, season after season.

- Incredible Value: You get serious performance and durability without the high cost and maintenance of rear suspension. This frees up budget for higher-quality components elsewhere.

The Modern Aluminium Hardtail: Evolved & Capable

The Trifox PeakTrail Xtreme MK7 exemplifies this allure. It’s not your grandad's rigid bike. Featuring:

- A lightweight, hydroformed aluminium frame with optimized tubing for strength and ride quality.

- Aggressive, modern geometry for confident descending and stability at speed.

- Premium suspension fork (like the Suntour Raidon) to smooth out the front end.

- High-performance drivetrain (Shimano SLX/XT) and powerful disc brakes for precise control.

Who Thrives on a Hardtail?

- Skill Builders: Learn proper technique and become a better rider.

- XC & Trail Racers: Maximize speed and efficiency.

- Value Seekers: Get top-tier performance without breaking the bank.

- Adventure Riders: Dependable, low-maintenance exploration machines.

- Riders Craving Connection: Those who want to truly feel the trail beneath them.

Ready to Embrace the Purity?

Experience the direct thrill and undeniable efficiency of a modern aluminium hardtail. The Trifox PeakTrail Xtreme MK7 delivers the perfect blend of performance, durability, and pure trail feedback. Rediscover why the hardtail remains a cornerstone of mountain biking.

Forget marginal gains – shedding significant weight from your bike's core fundamentally revolutionizes your experience. A super light frame isn't just a number; it's the key to unlocking a new dimension of riding.

The most dramatic transformation? Climbing. Less mass means defying gravity requires drastically less effort. Every pedal stroke feels more efficient, translating directly to faster ascents and reduced fatigue. Hills become challenges to relish, not dread. You accelerate quicker, maintaining momentum with newfound ease.

But the magic extends beyond going up. A lightweight frame enhances handling profoundly. It's more responsive to steering inputs, making cornering sharper and more intuitive. The bike feels like an extension of your body, dancing beneath you with agility. This flickability boosts confidence on descents and technical sections.

Acceleration is where a super light frame truly shines. Whether launching from a stop sign or surging out of a corner, the reduced inertia means the bike leaps forward with minimal effort. It feels eager, alive, translating your power into speed instantaneously. You spend less energy overcoming inertia and more maintaining exhilarating velocity.

The overall ride feel becomes exhilaratingly direct. Road buzz and minor imperfections are communicated, but the frame's stiffness (often inherent in lightweight designs like carbon) ensures power transfer is immediate and precise. You feel connected, efficient, and incredibly fast.

Experience this transformation: Ready to feel the climb vanish and the road come alive? The Trifox X16TA Disc Brake Lightweight Carbon Road Bike Frame embodies this revolution. Engineered for minimal weight and maximum performance, it's the foundation for your fastest, most responsive ride yet. Discover how a super light frame changes everything: Less weight, more ride.

Don't underestimate those humble rings stacked on your steerer tube! Stem spacers are silent heroes in dialing your bike's feel. Positioned above or below your stem, they fine-tune your cockpit’s height – impacting comfort, control, and speed. Here's how:

1. Fit & Comfort:

Spacers directly influence your stack height – the vertical distance from the bottom bracket to the stem. More spacers (or spacers below the stem) create a taller, more upright riding position. This:

Reduces strain on your back, neck, and wrists.

Improves comfort on long climbs or endurance rides.

Opens your chest for better breathing.

Fewer spacers (or spacers moved above the stem) lowers your front end for a more aggressive, aerodynamic posture – ideal for racing or maximizing power transfer.

2. Handling & Stability:

Raising your stem with spacers shifts your weight slightly rearward. This:

Makes steering feel slightly slower and more stable, especially at high speeds or on steep descents.

Increases front-wheel traction for confident cornering.

Lowering the stem shifts weight forward:

Quickens steering response for technical, twisty trails.

3. The Sweet Spot:

Finding your ideal spacer setup balances comfort and control:

XC/Endurance Riders: Often prefer more spacers for comfort during long efforts.

Trail/Downhill Riders: May run fewer spacers (or a slammed stem) for aggressive handling and weight distribution on descents.

Experiment Wisely: Adjust in 5-10mm increments. Never exceed your fork's steerer tube limit! Always leave a 3-5mm spacer above the stem for proper headset preload.

Pro Tip: Use durable, lightweight alloy spacers like Trifox's Precision Spacers. They maintain secure clamping force, resist corrosion, and keep your cockpit clean during adjustments.

The Takeaway:

Stem spacers are free performance tuning! Dialing your stack height optimizes your body's interaction with the bike. A minor tweak can reduce fatigue, boost confidence, and transform your ride. Don't just set it and forget it – experiment safely to find your perfect balance.

They're small, often overlooked, but your connection to the bike: handlebar grips. Choosing the right pair transforms control, comfort, and confidence on the trail. Forget one-size-fits-all – your perfect grip depends on riding style, hand size, and terrain. Here’s how to find your match:

1. Diameter & Feel:

Standard grips (typically ~30mm diameter) suit most riders. Larger diameters (32-34mm) reduce pressure points and suit bigger hands or those seeking vibration damping. Slimmer grips (28mm) offer precise control for technical riders. Consider cushioning density – soft grips absorb chatter but may lack precision; firmer grips boost feedback for aggressive riding.

2. Pattern & Tread:

Ribbed/Twin-Pattern: Balages grip and vibration absorption. Versatile for trail/enduro.

Knobby/Aggressive: Maximizes grip in wet/muddy conditions or for downhill. Can feel harsh on long rides.

Smooth/Minimalist: Lightweight and comfy for XC/less technical terrain.

3. Lock-On vs. Slide-On:

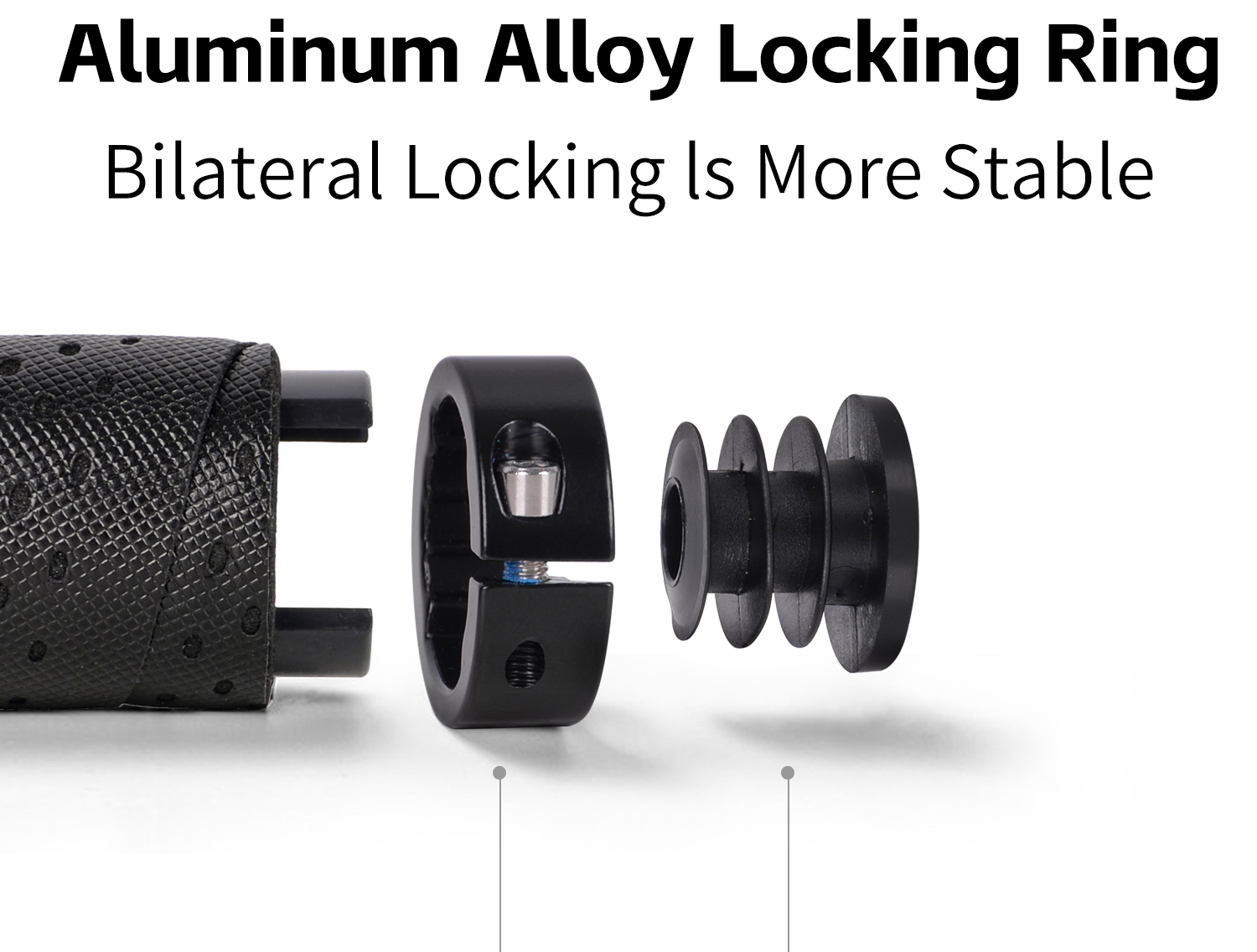

Lock-On grips (like the Trifox MBT100) feature aluminum clamps for secure, slip-free installation. Essential for rough trails, wet conditions, or riders preferring zero rotation. Slide-ons are lighter but require glue/wire and can twist.

4. Length & Flange:

Standard lengths (~130-135mm) fit most. Longer grips (~140mm) support multiple hand positions (e.g., cornering, climbing). Flanges provide a wrist stop for steep descents; flange-less offer a cleaner look and more hand placement options.

Why Consider the Trifox MBT100?

Dual-Density Construction: Firmer outer tread for precise control + softer inner base for vibration damping.

Aggressive Diamond Tread: Confident grip in all conditions without compromising comfort.

Durable Aluminum Clamps: Tool-free, secure installation that withstands impacts and mud.

Optimized Length (133mm): Versatile for most hand sizes and riding styles.

The Takeaway:

Don't settle for numb hands or slipping control. Experiment! Consider your trails, hand size, and preferences. Grips like the MBT100 offer a balanced, reliable upgrade – enhancing your connection to the trail without breaking the bank.

The 27.5" trail bike strikes a legendary balance: agile enough for tight corners, stable enough for chunk, and playful everywhere. But for years, a critical component often held them back – the fork. Enter high-modulus wonders like the Trifox T800 Carbon Boost Fork, fundamentally changing the game for 27.5" riders seeking pure trail performance.

The Weight Revolution:

Traditional alloy or lower-grade carbon forks add significant heft up front. T800 carbon fiber, renowned for its exceptional stiffness-to-weight ratio, slashes grams dramatically. Forks like the Trifox TMK200 tip the scales around a mere 450g. This unsprung weight reduction is transformative: your 27.5" bike becomes noticeably nimbler, accelerates faster, and flicks through technical sections with telepathic responsiveness. Climbing feels less of a chore as the front end stays light and precise.

Stiffness Meets Trail Agility:

Weight savings mean nothing without control. T800 carbon delivers incredible torsional and lateral stiffness. Paired precisely with the Boost 110x15mm thru-axle standard, this fork eliminates flex under hard cornering or braking. Your 27.5" wheels track exactly where you point them, inspiring confidence through loose berms and off-camber roots. Power transfer is direct, making every pedal stroke count. This stiffness isn't harsh; modern carbon layups absorb high-frequency trail buzz beautifully, enhancing control without sacrificing comfort on long descents.

Optimized for the Platform:

The 27.5" wheel thrives on quick handling and maneuverability. A rigid carbon fork like this amplifies those traits. Without suspension bobbing or diving, you get pure, unadulterated feedback from the trail. Steering input is immediate, fostering a deeply connected, "ride the tire" experience that sharpens skills and heightens fun. The tapered steerer tube ensures precise handling and integrates seamlessly with modern frames. Plus, the Boost spacing allows clearance for wider 27.5+ tires (often up to 2.8"), adding versatility for different terrains.

Durability & Simplicity:

文字

High-quality T800 carbon isn't just light and stiff; it's incredibly strong and fatigue-resistant. Rigid forks also ditch complex suspension components – no seals to service, no oil to change, no air springs to tune. It's maintenance simplicity defined, offering reliable performance ride after ride with minimal fuss. Disc brake specific (flat mount or post mount) ensures powerful, consistent stopping power.

The Verdict:

For 27.5" trail riders prioritizing agility, efficiency, and a pure connection to the trail, the T800 Carbon Boost fork isn't just an upgrade; it's a revelation. It unlocks the platform's inherent playfulness by shedding weight, boosting stiffness, and delivering unmatched precision. If you crave a more responsive, lively, and engaging ride from your 27.5" steed, this technology is the key. It transforms your bike into a sharper, faster, and more rewarding partner on every trail.

In mountain biking, weight is gravity’s currency. For racers and climb-obsessed riders, every gram shaved unlocks speed, agility, and that precious edge over rivals. At Trifox, this obsession birthed the SDY20 hardtail frame – their lightest 29er carbon chassis ever, engineered to turn ascents into triumphs.

The Magic Number: 930g

Weighing just 930 grams (size S, unpainted), the SDY20 isn’t just light – it’s a feat of carbon optimization. Using T1000 carbon with refined layering, Trifox achieves staggering stiffness-to-weight while maintaining trail-taming compliance. This frame isn’t delicate; it’s intelligently minimal.

Why Lighter = Faster?

- Acceleration: Less mass to propel uphill = instant response when you stamp the pedals.

- Agility: Flickable on switchbacks and effortless to loft over roots.

- Endurance: Reduced fatigue = more watts left for the final kick.

Race-Ready DNA Beyond Weight:

- XC Geometry: A 68.5° head angle and 445mm reach balance stability and razor-sharp precision.

- Boost Spacing: 148x12mm rear / 110x15mm front maximize stiffness and wheel compatibility.

- Stealth Integration: Full internal routing (brakes + dropper) for clean looks and snag-free rock gardens.

Modern Trail Specs: 1x-only, tapered head tube, and room for 2.4" tires.

Who Is the SDY20 For?

- XC Racers: Chase podiums with a frame born for efficiency.

- Climb Conquerors: Transform suffering into flow.

- Weight Weenies: The ultimate gram-shavers'canvas.

The Verdict:

The SDY20 isn't just a frame – it's Trifox's love letter to climbing. By ruthlessly cutting grams without sacrificing stiffness or control, it delivers a ride experience where the bike disappears beneath you, leaving only you, the trail, and the summit ahead.