The biggest challenge of the early tires was how to properly and reliably fix them on the rim. The method of bonding to the rim was very effective in the past, but there is no shortage of other fixing methods, such as hook-shaped rims and wire binding. But these methods are too complicated, and finally evolved to the present, clincher, tubeless, and tube have become the most mainstream form. Nevertheless, the debate on the performance and advantages of different tires is still fierce.

The ideal tire:

The ideal bicycle tire has lightweight, has good puncture resistance, excellent grip, not too short a life span, is a reasonable price, has low rolling resistance, and comfort. But these are ideals after all. In reality, many elements are mutually exclusive. Under the current technical background, ultra-light tires do not have very good puncture resistance. Therefore, we often have to compromise on one or more performances. The choice depends on our actual needs.

Many people regard the tire as a static structure with a single function-a rubber tube, which contains gas, but there are many factors acting on the tire on the road. In fact, the tire is dynamic and constantly changes its shape to adapt to road changes. Wheel angle and rider's weight.

It is for this reason that the flexibility of the tire is a precious feature. When the wheel is rolling on the ground, the softer tire is easier to fit and rebound, and its grip, rolling resistance, and overall feel are better.

The choice of material largely determines the final weight, softness, and durability of the tire. Lightweight materials are often used to produce high-speed tires with low rolling resistance and soft surfaces, but their puncture resistance is not strong. Easy to wear and expensive. Heavy materials can enhance puncture resistance, wear and cost less, but have higher rolling resistance and decreased comfort. These principles also apply to the clincher, tubeless or tubular tires.

Similarity:

1. All three types of tires include a braided shell, which covers the air chamber and is covered with a rubber tread.

2. Use the same material or manufacturing process.

3. The appearance is similar when installed behind the wheel.

4. These three tires can be designed specifically for different riding habits, performance, price, and usage scenarios.

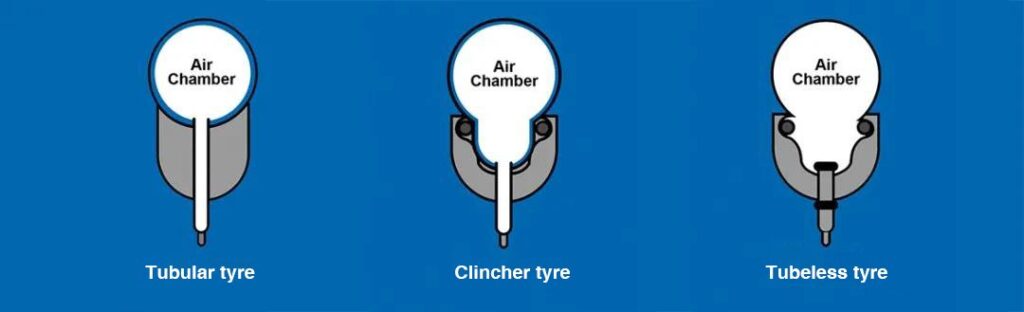

In contrast, the difference between the three tires becomes simple-how to form and accommodate the air chamber. For tube tires, the air chamber is completely enclosed inside the tire. The open tire needs an inner tube to contain the gas. The tubeless tire itself is an air chamber, but it needs to be matched with a special tubeless rim.

To choose a tire, look at the wheel first:

Each tire system needs a special rim to match, in other words, the user should choose the tire according to the existing rim. Tube tires cannot be used on clincher wheels. Clincher or tubeless tires cannot be installed on tube tire wheels. Clincher tires can be installed on wheels that support tubeless tires, but inner tubes must be used. Tubeless tires can also be used. It is installed on a standard clincher wheelset, but it can no longer be used as a tubeless tire and can only be used with inner tubes.

The design of the tubular tire wheelset is different from the design of the conventional clincher wheelset. On both sides, there is no hook-like sidewall and reinforcement to fix the tire. Therefore, the rim of the tubular tire is always lighter than the same clincher rim and has a concave section. The tubed tire can be properly placed, but the safety of the tube tire depends on the quality of the glue or tape.

Tubeless tires are similar to the rims of standard clinchers but are more refined. Both have similar sidewalls (although some tubeless tires have used flat sidewalls without hooks), and the inside of the rim is similar to ridges and ridges. The tubeless tire bead on both sides of the tube is more compact than the clincher, so the airtightness of the tubeless rim and the tire will be significantly higher than the clincher wheelset. These ridges cooperate with the bead of the tubeless tire to form an airtight seal, which also explains why the tubeless tire will hear a snapping sound when it is pumped up. The tubeless tire must also be separated from these ridges when replacing or repairing.

For dedicated wheels, it is difficult for users to mix different types of tires, but using suitable rim tape (to seal the rim spoke openings), vacuum nozzles, and sealants, some common open tire wheels can also be used. Tubeless tires were modified to seal the tire pads, and tubeless tires were used instead.

Material and structure:

Some people believe that one type of tire must be better than another type. However, under the same material, the difference between different tires is very subtle. More differences depend on the material used in the tire. Any light and soft tire can bring smoothness and speed. The riding experience, whether tube or not.

The three types of tires have the same type of material to form the tire casing and tread. Nylon is often used to weave the casing, rubber is commonly used in the tread, and others such as Kevlar, bulletproof fiber Vectran, and graphene. Or cotton and silk are only used as reinforcement, not completely replaced.

The casing is woven by threads. The finer the thread, the more the number of threads. The unit of measurement is the number of threads per inch, which is the so-called TPI. Fine tires can reach up to 320tpi. The low line count is lighter and more supportive.

Bicycle tires use a lot of rubber to improve the overall feel of the tire. For most tires, the tread is vulcanized by heating, adding a curing agent, and fused with the tire, but this will harden the tire, and soft tires are often glued. The rubber is fixed to the casing by the agent. The hand-made tubular tires and the so-called "open tubular tires" (used in clincher wheels, tubular tires with bead) are to avoid vulcanization as much as possible to ensure the flexibility of the tire.

For the tire tread, there is no intuitive evidence that the tread pattern will directly and greatly affect the grip (limited to road vehicles), and more importantly, the user's air pressure.

Impact resistance:

No matter what kind of tire, more or less anti-puncture materials are used, depending on whether the final weight of the tire is important. However, puncture-resistant materials will make the tires harder, and bumpier, and increase road resistance. Therefore, they will be used with caution in competition tires. In contrast, strong and heavy commuter tires use a lot of Anti-puncture material and have greater impact resistance.

There is no such thing as a car's explosion-proof tire on a bicycle. Of the three tires, tubeless tires undoubtedly have advantages here. This kind of tire is resistant to squeezing and pressure. The repair fluid in the tubeless tire can automatically repair minor cracks, but the sidewall has a large cut. It will still damage the sealant and cause the tire to leak.

Tubeless tires are very beneficial for off-road riders, because tubeless tires can be used at an air pressure of less than 40psi or less than 3bar, and can increase extra grip and traction, but for road bike riders, this advantage is not What's the big use, it is the lack of tube tires and opens inner tube structure, which slightly reduces the friction between tires. Users of Adventure or Gravel Bike may prefer tubeless tires, but tubeless tires are not a prerequisite for on-road and off-road.

Larger size tires have larger air chambers (air intake), which can allow lower air pressure and obtain the same degree of expansion without having to enter too high air pressure, so it can also increase the comfort of the bicycle.

Installation, maintenance, and repair:

For most ordinary riders who do not have logistical services, choosing any tire system is simply inconvenient for later maintenance. In this regard, ordinary clinchers have great advantages. The tube tire installation process requires a certain amount of man-hours and a certain amount of experience, which is a difficult task for beginners, although the tube tire double-sided tape has simplified the entire process. After the tube tire ruptures, the repair liquid filled in can be used for short-term remediation, but some repairs can not be applied to high pressure, so it is not as practical as replacing the new tube tire.

Installing a tubeless tire for the first time is also challenging. The rim must be kept sealed, the vacuum nozzle must be installed correctly, and enough sealant must be added to the tire. Although it is possible to use an air pump to inflate the tubeless tire, an air compressor with a larger instantaneous air intake is a better choice.After installation, the tubeless tire promises a longer maintenance interval, but the wear of the tire cannot be ignored. The sealant will slowly dry over time. When the repair fluid or sealant is dried, the perforation of the tire will not be repaired, so The sealant needs to be added every few months.The perforated tubeless tire casing can be repaired using conventional repair methods, but the inner wall of the casing with the sealant is very smooth, and the adhesive and the tubeless tire repair fluid will interact.

Cost and product line:

As the main tire system, there are many open tires on the market for consumers to choose from. There are various handmade tires on the high-end market. The lightweight folding tires are suitable for competition and training. On the other hand, sturdy steel tires are cheap enough and suitable for commuting. , In short, clinchers of all prices can be found.

Expanding to the inner tube of the open tire, we can find several kinds of standard butyl inner tubes, puncture-proof inner tubes, lightweight butyl inner tubes, and latex inner tubes on the market. The difference between them is often very small, and the weight, road feel, and stab resistance are not What is the amazing gap?

Tubeless tires are a relatively new product, so there are not as many options as clincher tires, and these tires are usually more expensive.

Tubular tires are often expensive, but there are also less expensive training-grade tubular tires on the market to reduce weight and increase comfort. Unfortunately, a tire puncture may end the life of the tubular tire, so the ongoing cost of maintaining a set of tubular tire wheels may be high.

Tubular tires: It has long been recognized as the golden choice for competition-level road bikes. Tubular tires are widely used by professional riders. However, because of the difficulty and time-consuming installation and maintenance, tubular tires have only limited appeal to ordinary riders. However, tubular tires can provide the greatest weight savings.

Purpose: race, training, cross-country, long-distance

Advantages: lightweight, matched wheels are also very lightweight, and more resistant to "snake bites" compared to clinchers.

Disadvantages: Installation is more difficult, and it cannot be quickly repaired by the roadside. Tubular tire repair technology can be called "world cultural heritage" (true and manual stitching).

Need accessories: special tube tire wheelset, tube tire glue, or tube tire double-sided adhesive

Maintenance: Need to check the tire tread wear and check the adhesion of the tire to the wheel

Cost: Above average, although it is possible to buy tube tires at their early cost of 60usd, the double-sided tape required adds additional costs. Users should spend time learning to install them on their own to save costs.

Clincher tires: Clincher tires are not as popular as the other two types of tires. Clincher tires are everywhere, and the ease of use in the tire system is far superior to other competitors.

Purpose: race, training, cross country, commuting, long-distance.

Advantages: simple installation, convenient disassembly, everywhere, many products.

Disadvantages: low pressure is easy to "snake bite", steel wire tires increase weight, hook-shaped bead increases the overall weight

Need accessories: clincher wheelset, tire pad, inner tube

Maintenance: detection of tread wear and foreign matter

Cost: From high to low, consumers will face a huge product range, ranging from 30 USD to 100 USD. The inner tube is relatively cheap, but it is a continuous cost.

Tubeless tires: As a new product in the market, tubeless tires are favored by off-road enthusiasts because of their excellent puncture resistance. There may not be many tubeless tires for roads, but these products have made great progress.

Purpose: race, training, cross country, commuting, long-distance

Advantages: Excellent puncture resistance, low tire pressure can be used, and repair fluid provides additional puncture resistance.

Insufficiency: Installation requires technology, product types are limited, and maintenance is rather chaotic (mending fluid overflows)

Need accessories: Tubeless tire wheelset, tire pad, tubeless tire valve, repair fluid sealant, compressed air

Maintenance: Detect the tread wear and replenish the repair fluid for a few months

Cost: Medium to high. Tubeless tires are often more expensive than clinchers. Tire pads and air nozzles can be regarded as one-time costs, but the repair fluid will be a long-term cost, requiring considerable time for maintenance and some equipment. For example, compressed air tanks or air compressors.

How to decide which tire system to use:

From the above discussion, it is not difficult to find that each tire system has its advantages and disadvantages. In general, high-end clinchers (cotton tube structure) and tubeless tires have been able to achieve or even exceed the performance of tubular tires. For truly lightweight users, tubular tires are the best choice. For most riders, the easy-to-maintain clincher has obvious advantages. However, the choice of tires is sometimes not completely arbitrary, depending on what the existing wheels can be used. After all, the cost of changing wheels is much greater than the cost of changing tires.