The perception that carbon fiber mountain bikes are delicate relics of road cycling has been thoroughly dismantled by modern engineering. Today's carbon hardtail frames are purpose-built to endure the punishing realities of trail riding while delivering the weight savings and performance benefits that make carbon so desirable. Understanding how frames like the Trifox SDY20 withstand trail hazards reveals the sophisticated engineering behind what appears to be a simple frame.

Modern carbon engineering begins with material science advancements. Unlike early carbon designs that used single-direction layups, current frames employ multi-directional carbon fiber weaves with varying modulus fibers. High-modulus fibers provide stiffness in critical areas like the bottom bracket and head tube, while more flexible fibers in seatstays and chainstays absorb impacts. This strategic fiber placement creates frames that are simultaneously stiff where you need power transfer and compliant where you need shock absorption.

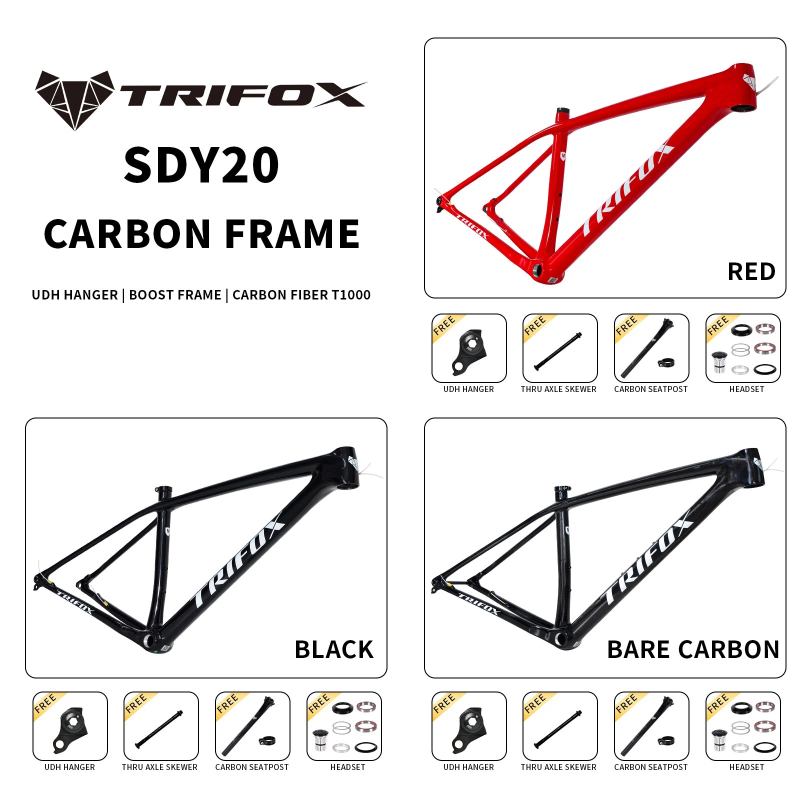

Impact resistance represents one of carbon's most misunderstood qualities. When properly engineered, carbon frames demonstrate remarkable resilience to trail impacts. The SDY20 light hardtail frame utilizes reinforced zones at common impact points: thicker carbon layups around the downtube where rocks might strike, reinforced chainstay protectors, and impact-resistant finishes. Unlike aluminum that dents permanently or cracks catastrophically, quality carbon construction often shows visible damage before catastrophic failure, giving riders warning signs.

Fatigue resistance is another critical factor. Trail riding subjects frames to thousands of vibration cycles and stress fluctuations. Carbon's natural vibration-damping properties reduce rider fatigue, but more importantly, modern resin systems and curing processes create bonds that resist micro-cracking under repetitive stress. The 19 inch bike frame and other sizes in the SDY20 lineup undergo rigorous fatigue testing that simulates years of aggressive trail use, ensuring long-term durability.

Connection points receive special attention in trail-oriented carbon frames. The SDY20 features reinforced interfaces where components attach: extra carbon layers around the 148mm Boost axle dropouts, strengthened bottle cage mounts, and oversized bearing seats for headset durability. These reinforcements prevent the common failure points that plagued early carbon mountain bikes, ensuring the frame maintains integrity through years of component swaps and maintenance.

Frame geometry itself contributes to durability. Modern trail geometry with slack head angles and longer top tubes distributes impact forces more evenly throughout the frame structure. Rather than concentrating stress at specific points, the frame works as a complete system to absorb and dissipate trail energy. This holistic approach to stress management means frames can be lighter while actually being more durable than their predecessors.

Quality control and testing protocols separate modern carbon frames from earlier generations. Each SDY20 frame undergoes multiple inspection stages including ultrasound scanning to detect voids or inconsistencies in the carbon layup. Impact testing simulates rock strikes, fatigue testing replicates years of trail abuse, and static load testing ensures the frame can withstand forces far beyond normal riding conditions. This comprehensive testing provides the confidence needed for aggressive trail use.

To back this engineering confidence with customer assurance, Trifox provides a 2-year warranty on the SDY20 frame against defects in materials and workmanship under normal use. This warranty commitment underscores the brand's confidence in their carbon engineering and manufacturing processes. It means riders can invest in this lightweight carbon technology with peace of mind, knowing their frame is protected against unexpected manufacturing issues during years of trail enjoyment.

The result is a light hardtail frame that defies outdated perceptions. At approximately 930 grams for the frame(size S), the SDY20 offers significant weight savings over comparable aluminum frames while providing equal or better impact resistance. The weight savings translate directly to trail performance—easier climbing, quicker acceleration, and more playful handling—without sacrificing durability.

Ultimately, modern carbon engineering has evolved to meet the specific demands of trail and XC riding. Through advanced material science, strategic reinforcement, intelligent geometry, rigorous testing, and warranty support, frames like the Trifox SDY20 demonstrate that carbon can be both exceptionally lightweight and remarkably tough. For riders who want the performance benefits of carbon without compromising trail readiness, today's engineered carbon hardtails represent the perfect synthesis of technology and durability.