In the world of road cycling, a certain unwritten rule has long been accepted: true performance carbon fiber comes with a premium price tag. Independent brand framesets often start well above $700, creating a high barrier to entry. Today, that rule is being decisively broken. Trifox is turning the market on its head with the X10 Disc Road Frameset, now offered at a jaw-dropping clearance price of just $359 USD. This isn't a stripped-down compromise; it's a complete, modern carbon platform that challenges everything you thought you knew about value in cycling.

Deconstructing the Price: Where Value Truly Comes From

The immediate question is: how? The answer lies not in cutting corners, but in smart, efficient engineering and a direct-to-consumer model. Trifox bypasses traditional retail markups and invests directly into manufacturing and design. By leveraging mature, high-volume carbon fiber production pipelines and focusing budget on core structural performance rather than extravagant marketing or superfluous features, they deliver exceptional quality at an unprecedented price point. The X10 proves that premium materials and modern standards don't have to be a luxury.

The Specs That Matter: A Modern Foundation

The X10 isn't a relic being cleared out; it's a contemporary frameset built to current expectations. It's constructed from high-modulus T800 carbon fiber, offering the stiffness and lightweight characteristics riders seek. It embraces the modern standard of internal cable routing, yielding a clean, aerodynamic profile free of cable clutter. As a dedicated disc brake frame, it provides consistent, powerful stopping in all conditions, paired with flat-mount caliper fittings for a tidy interface.

The frame features a tapered head tube (1-1/8" to 1-1/2") for precise, confident steering. Critically, it offers generous tire clearance, welcoming 700c tires up to 28mm wide, which opens the door to enhanced comfort and versatility on rougher roads. Available in a comprehensive size range, including a 58cm road bike frame for sale, it ensures a proper fit for a wide variety of riders. The package is complete, including the carbon frame, a matching full-carbon fork, and a carbon seatpost.

The Perfect Project Canvas: Who Is This For?

The X10 is a dream canvas for specific, savvy riders:

1. The First-Time Carbon Builder: For anyone who has dreamed of building a carbon bike but was halted by frame cost, this is your gateway. It allows you to allocate more of your budget to high-quality wheels and components.

2. The Value-Obsessed Enthusiast: Riders seeking the best cheap bike frames that don't sacrifice modern features will find the X10 irresistible. It's a chance to own a legitimately high-performance frameset for the price of many mid-tier alloy frames.

3. The Dedicated "B" Bike Builder: Need a reliable, foul-weather training bike, a dedicated smart trainer frame, or a travel bike? The X10 provides a premium-feeling base without the anxiety of damaging a $2,000 frame.

Build Inspiration: Your Dream Bike on a Budget

Imagine building around the X10: Pair it with a dependable Shimano 105 R7000 groupset, a set of dependable alloy wheels, and quality finishing kit. For well under $1,500 total, you can assemble a carbon road frame-based bike that rivals the performance and ride quality of off-the-shelf machines costing twice as much. The X10 provides the sophisticated, efficient foundation; you choose how to bring it to life.

The Trifox X10 Frameset is more than a sale item; it's a statement. It dismantles the old price-performance paradigm and delivers genuine carbon performance to a broader audience. At $359, it’s not just an affordable frame—it’s one of the most compelling value propositions in cycling today. For the builder who knows where to look, the rules have just changed.

When a new carbon frame like the Trifox X16TA is released, the spec sheet tells one story: weight, geometry, and compatibility. But the true measure of a frame is written over thousands of kilometers, across varied terrain, and through every season. We’ve lived with the X16TA for months, using it as the foundation for a high-performance build. This is the long-term review that goes beyond the numbers to reveal what it’s genuinely like to ride.

First Impressions & Build Quality: A Clean Slate

Out of the box, the first thing that strikes you is the clean, purposeful aesthetic of the black frames. The finish is high-quality, with a deep, consistent gloss or sleek matte option that has proven resistant to scuffs and minor chips. As a 700c frameset, it presents a modern, balanced silhouette ready for a build. The internal cable routing ports are well-finished, and the overall mold quality shows precise carbon layup with no visible imperfections. Threads for the bottom bracket, derailleur hanger, and accessories were clean and required no chasing, speaking to careful manufacturing.

The Ride Character: Where Stiffness Meets Sensation

The spec sheet highlights a low weight, but the on-road character is defined by its excellent stiffness-to-weight ratio. From the first pedal stroke, the frame communicates efficiency. There’s an immediate, direct transfer of power that makes acceleration feel crisp and sprinting feel authoritative. The bottom bracket area is particularly rigid, with no discernible flex under high-torque efforts, whether climbing out of the saddle or launching from a stop.

However, this isn’t a harsh, unforgiving race frame. The X16TA exhibits a well-engineered level of vertical compliance. Over broken pavement and long stretches of coarse chip-seal, the frame does a remarkable job of taking the sharp edge off high-frequency vibrations. This isn’t the muted, floating feel of an endurance bike, but rather a refined firmness that keeps you connected to the road while significantly reducing fatigue in your hands and back over three or four-hour rides. It strikes a compelling balance between race-day responsiveness and all-day rideability.

Geometry & Handling: Predictable Precision

The geometry is modern and balanced. The head tube angle and fork rake yield handling that is stable at high speed yet nimble in corners. It descends with confident, planted manners, inspiring trust when leaning into switchbacks. At the same time, it’s quick to change direction, making it lively in technical, rolling terrain. This is a frame that feels equally at home in a fast paceline as it does on a solo mountain pass—it doesn’t force a single style but adapts to the rider’s input.

Durability & Long-Term Impressions

After months of use in all conditions, the frame has shown impressive resilience and reliability. The disc brake mounts have remained perfectly aligned, with no creaks or issues. The Internal cable routing, while requiring patience during the initial build, has remained silent and functional. The high-modulus carbon construction shows no signs of wear or softness, maintaining its original lively feel. It’s a frame that disappears beneath you in the best way, becoming a reliable, predictable extension of the rider that asks for little beyond routine maintenance.

The Verdict: A Frame That Grows With You

The Trifox X16TA transcends its spec sheet. It’s more than just a lightweight disc brake road bike frame; it’s a thoughtfully engineered platform that delivers a premium riding experience. It offers the stiffness a performance rider craves, tempered with a level of comfort that encourages long days in the saddle. Its versatile geometry and robust construction make it a perfect candidate for a dedicated race build, an all-rounder sportive machine, or a high-performance daily trainer. If you’re looking for a carbon road frame that provides exceptional value by blending race-ready performance with real-world refinement, the X16TA is a compelling choice that continues to impress long after the novelty has worn off.

TRIFOX X11 Road Bike Frame Launched | full internal. Ultralight · 700 * 35C

The pursuit of the perfect road bike frame is a relentless chase for harmony: featherweight agility paired with unshakable stiffness, aerodynamic efficiency balanced with real-world versatility, and timeless aesthetics integrated with future-proof technology. This pursuit has a new benchmark. Trifox is proud to unveil the X11—a next-generation road cycle frame that doesn't ask you to choose, but masterfully delivers on all fronts. It's engineered not just to be ridden, but to redefine your expectations of speed, comfort, and precision.

At the core of the X11's philosophy is an uncompromising commitment to ultralight performance. Meticulously crafted from our highest-grade T800 and T1000 carbon fiber, the frame achieves a staggering sub-900-gram weight (size dependent) through advanced monocoque molding and strategic material layup. This isn't weight saved for its own sake; it's mass meticulously removed to create a bike that responds to the slightest input, accelerates with explosive urgency, and makes every climb feel like an opportunity. It's a pure, unadulterated connection to the road.

The X11 embraces a fully integrated, clean-sheet design. Every cable and hose is routed internally through the headset and frame, creating a flawlessly sleek silhouette that slices through the air. This isn't just about aesthetics; it's about eliminating drag and presenting a unified front against the wind. The engineering behind this is sophisticated, featuring internal guides and reinforced entry points to ensure smooth installation and long-term reliability, proving that clean looks and robust function are not mutually exclusive.

This frame is built for the modern era of road cycling. It discards outdated standards in favor of reliable, high-performance technology:

* Unified Derailleur Hanger (UDH): Embracing the industry-standard UDH future-proofs your investment. It ensures wide compatibility with current and future drivetrain innovations and simplifies maintenance with an easily replaceable, universal hanger.

* T47 Threaded Bottom Bracket: At its heart lies a T47 threaded shell, offering the creak-free security of threads with the increased stiffness and bearing support of a oversized design. It's the perfect blend of reliability and performance.

* Expanded Tire Clearance: With ample room for 700x35c tires, the X11 shatters the old boundaries of a race bike. It invites you to fit robust rubber for sublime comfort on rough pavement, confident exploration on smooth gravel, or simply to run lower pressures for enhanced grip and ride quality—all without sacrificing its racing pedigree.

The X11's geometry is the final piece of the puzzle. Developed with input from dedicated riders, it strikes an ideal balance between a responsive, agile race feel and stable, confident handling at high speeds. This precise calibration makes it equally at home attacking in a local criterium, carving through mountain descents, or powering through a long solo breakaway. It's a frame that inspires confidence to push limits.

For the racer seeking every competitive edge, the X11's design and geometry are conceived with UCI road compliance in mind, making it a potent weapon for sanctioned competition. But its appeal is far broader. It is the ultimate foundation for the discerning enthusiast who demands a bike that is breathtakingly light, technically sophisticated, and adaptable enough for any road ahead. The Trifox X11 isn't just a new frame; it's a new standard for what a modern, ultralight road cycle frame can be.

Why Our Internally Routed Frame Rides Stiffer and Lighter

It’s a brilliant question: “If you’re drilling holes in the frame for cables, doesn’t that make it weaker?” It’s a completely reasonable assumption. In the world of modern carbon fiber engineering, however, the answer is a definitive "no." The key is that in a high-performance frame like the Trifox SDY21, these internal channels are not an afterthought or a destructive cut into a finished structure. Instead, they are precisely calculated engineering features integrated from the very first stages of Finite Element Analysis (FEA). Our goal is not to choose between beauty and performance, but to engineer a solution that wins on all fronts: superior aesthetics, enhanced rigidity, and reduced weight.

Localized Reinforcement & Structural Design: Think of it like the engineering of a modern building. A window isn't just a hole in a wall; it’s surrounded by a reinforced lintel that redistributes load. Similarly, around every critical entry and exit point in the SDY21 frame—especially the head tube—we apply additional carbon fiber layers and localized reinforcement. We use strategic patches of higher-modulus T800 carbon in these high-stress areas. This targeted reinforcement ensures the structure is actually stronger at its most vulnerable points, turning potential weaknesses into fortified zones. Furthermore, the internal channels themselves are designed with specific, stiffness-enhancing shapes, effectively becoming integrated structural elements rather than simple voids.

Holistic Engineering and Structural Integrity: A high-performance carbon frame is not a collection of tubes; it is a singular, unified monocoque structure. The rigidity comes from the entire shape and the continuous carbon fiber layup. By designing the internal routing paths as an integral part of this holistic structure from the start, we can model and mitigate any localized stress concentration. The frame’s overall stiffness and strength are engineered to meet or exceed rigorous international standards (such as ISO 4210) with the routing channels fully accounted for. This means the SDY21’s structural integrity is validated as a complete system, proving that intelligent design can incorporate functionality without sacrificing robustness.

The proof is in the performance. The Trifox SDY21 isn’t just about a clean look. This rigid frame mtb achieves an exceptional stiffness-to-weight ratio. The compact 19 inch mtb frame size weighs in at just 1075 grams, a benchmark that rivals many premium hardtails. This staggering lightness is achieved without sacrificing the direct, responsive feel that serious XC and trail riders demand. The clean internal routing eliminates external cable drag and snag points, contributing to a more aerodynamic and maintenance-friendly package.

Ultimately, a superior full-internal routing design like that of the SDY21 represents a higher level of engineering sophistication. It moves beyond the old compromise. The result is a frame that is not only sleeker and easier to maintain but also stiffer and lighter—a true triathlon of benefits that elevates your ride. It’s engineering that works smarter, delivering a lightweight hardtail frame where every element, including the cable paths, contributes to the ultimate goal: a faster, more efficient, and more connected ride on the trail.

You're carving through a loose, off-camber corner, or powering over a chattery rock garden. You feel the bike begin to squirm, the rear tire searching for traction in a way that feels unpredictable and unnerving. That unsettling sensation of the back end stepping out isn't just about tire choice or suspension setup—it's often the hidden culprit of insufficient lateral stiffness in the rear triangle.

The rear triangle—comprising the chainstays, seatstays, and dropouts—faces a profound engineering conflict. It must be vertically compliant enough to allow the suspension to work and absorb bumps, yet laterally rigid enough to act as an unwavering lever for your drivetrain and a stable anchor for your rear wheel. When you stomp on the pedals or lean the bike into a turn, any lateral flex in this structure translates directly to energy loss and a vague, wandering feel from the rear wheel. In the quest for lightweight performance, lateral stiffness is often the first casualty, but it's the very foundation of predictable handling.

This is where the intelligent application of carbon fiber transforms the game. Unlike isotropic metals, carbon is anisotropic, meaning we can engineer its strength directionally. In the TRAIL II PRO carbon fiber 29er frame, we strategically orient T800 carbon fiber layers. We reinforce high-stress zones—like the outsides of the chainstays and the critical junction where the stays meet the forged carbon dropout—with extra, specifically angled plies. This creates localized "hard points" of immense stiffness exactly where they're needed to resist twisting forces from pedaling and cornering, without adding unnecessary weight or compromising vertical compliance elsewhere.

At Trifox, our solution is embodied in specific design choices. The TRAIL II PRO frame utilizes a box-section profile for the chainstays. This shape inherently provides greater resistance to twisting and side-to-side bending than a traditional round tube. Furthermore, we employ an asymmetrical design, with a subtly reinforced drive-side chainstay to counteract the powerful twisting forces generated by the drivetrain. These stays are then integrally molded with the main front triangle and the robust, Universal Derailleur Hanger (UDH)-compatible dropout, creating a singular, unified structure that behaves as one solid unit under load.

The result of this focused engineering is a 19 inch mtb frame (and 17") that translates technical specs into pure riding confidence. For the rider, it means the rear tire tracks your chosen line with tenacity, whether you're navigating a rutted climb or railing a high-speed berm. You can commit to corners earlier, power out of exits with everything you have, and trust that every watt you put into the pedals is converted into forward motion, not wasted in frame flex. The TRAIL II PRO’s rear triangle stiffness isn't a mere specification; it's the invisible hand that delivers a planted, precise, and supremely confident ride, unlocking the true potential of a lightweight carbon fiber 29er frame.

The quest for the perfect road bike frame is an endless pursuit of balance—stiffness versus comfort, weight versus durability, and agility versus stability. It often feels like a compromise. What if the next evolution wasn't about choosing one over the other, but about achieving it all in one meticulously engineered package? The wait is almost over. We are thrilled to offer a first glimpse at a project that redefines these boundaries: the upcoming X11. This isn't just another frame; it's a statement of intent, engineered from the ground up to be the lightest, most versatile, and technologically advanced platform in its class.

A New Benchmark in Weight and Performance

At the heart of the X11 lies a stunning achievement in material science and layup engineering. Crafted from advanced framed carbon, the size XS frame tips the scales at a mere 890 grams (with a +/-20g tolerance). This isn't just a lightweight frame; it represents the pinnacle of our manufacturing, where every gram is scrutinized and every layer of carbon is strategically placed to optimize the strength-to-weight ratio. This extreme lightness translates directly to the ride: explosive acceleration, effortless climbing, and a lively, connected feel that makes every watt count. For riders seeking a 54cm frame or other sizes, this philosophy of minimal weight and maximal performance carries through the entire size range.

Engineered for the Modern Road and Beyond

The X11 is built for the way we ride today—fast on the road, confident on rough pavement, and ready for adventure. It discards outdated standards in favor of modern, reliable, and versatile technologies:

* Uncompromising Stopping Power: Full disc brake integration with flat mounts ensures consistent, powerful braking in all conditions, from alpine descents to wet commutes.

* Future-Proof Compatibility: At its core is a T47 threaded bottom bracket. This oversized standard offers the creak-free reliability of threads with the increased stiffness and bearing life of a larger shell, ensuring compatibility with a wide range of cranksets now and in the future.

* The Universal Solution: Embracing the UDH (Universal Derailleur Hanger) is a commitment to simplicity and sustainability. This industry-standard hanger is widely available, making replacements after a crash quick and inexpensive, and future-proofing the frame for upcoming drivetrain innovations.

Versatility as a Core Feature

True performance isn't limited to smooth tarmac. The X11's design acknowledges the growing demand for one-bike versatility. With clearance for tires up to 700x35c, it seamlessly bridges the gap between a razor-sharp road machine and a capable gravel explorer. This allows you to fit robust, high-volume tires for comfort on long rides, traction on light gravel, or confidence in imperfect weather, all without switching bikes.

The Trifox frame engineering philosophy has always been about delivering exceptional value through direct design and manufacturing. The X11 is the culmination of this approach. It takes the lessons learned from countless miles on the road and distills them into a frame that is as intelligent as it is beautiful.

We are on the cusp of revealing the complete picture: the full geometry, the aesthetic details, and the final specifications. The X11 is more than a frame; it's the foundation for your next dream build—a platform that is staggeringly light, technically sophisticated, and ready for any challenge you throw at it.

Stay tuned. The revelation is coming soon.

A great bike is more than the sum of its parts—it's an extension of your body. No matter how advanced your components, improper bike fit can lead to discomfort, inefficiency, and even injury. Achieving the right fit transforms your riding experience, maximizing both comfort and performance. This is especially crucial when you're investing in a precision-engineered racing frame like the Trifox X16QR, where every advantage of its lightweight frame design should work in harmony with your physiology.

The importance of proper bike fit begins with performance optimization. A well-fitted bike allows you to generate power efficiently through an optimal pedaling motion. When your saddle height, fore/aft position, and handlebar reach are dialed in, you engage the correct muscle groups, reduce energy waste, and maintain an aerodynamic position longer. This is where a quality lightweight frame truly shines—its stiffness and responsiveness translate your effort directly into speed, but only if your body is positioned to deliver that power effectively.

Comfort and injury prevention are equally critical. Poor fit is the leading cause of common cycling ailments: knee pain from incorrect saddle height, lower back strain from excessive reach, or hand numbness from improper weight distribution. A professional fit addresses these issues by aligning your joints and distributing pressure appropriately. The Trifox X16QR racing frame, with its multiple size options and modern geometry, provides the ideal starting point for achieving this balanced position.

Achieving your perfect fit involves several key measurements and adjustments:

1. Frame Size Selection: This is your foundation. The Trifox X16QR comes in multiple sizes to accommodate different body proportions. Your ideal size is determined primarily by your inseam measurement and torso length, not just overall height. A frame that's too large forces excessive reach, while one too small leads to cramped positioning.

2. Saddle Position: Start by setting saddle height so your leg has a slight bend (25-35 degrees) at the bottom of the pedal stroke. Then adjust fore/aft position so your knee is directly above the pedal spindle when the crank is horizontal (the KOPS method). This ensures proper knee alignment and power transfer.

3. Handlebar Reach and Drop: Your handlebar position determines your upper body comfort. Reach (distance from saddle to bars) should allow a comfortable bend in your elbows without straining your back. Drop (height difference between saddle and bars) affects aerodynamics and back angle—more aggressive for racing, more relaxed for endurance.

4. Cleat Position: For riders using clipless pedals, cleat positioning on your shoes dramatically affects knee alignment and pedaling efficiency. Cleats should generally align with the ball of your foot, with slight adjustments based on your natural foot angle.

For the most accurate results, consider a professional bike fit. Many bike shops offer fitting services using motion capture technology, pressure mapping, and experienced fitters who understand biomechanics. While this represents an additional investment, it's often the most valuable upgrade you can make to your cycling experience.

When working with a high-performance frame like the X16QR, attention to component compatibility enhances your fit. The frame's geometry is designed for modern component standards, allowing precise adjustments through stem length, handlebar width, and crank arm length. Its carbon construction provides the stiffness needed for efficient power transfer while offering some compliance for long-ride comfort.

Ultimately, the perfect bike fit is personal and evolves with your fitness and riding goals. The Trifox X16QR provides an excellent platform with its multiple size options, modern geometry, and lightweight frame construction. By taking the time to dial in your position—whether through professional help or careful self-measurement—you'll unlock the full potential of your equipment. You'll ride faster, farther, and with greater enjoyment, proving that the right fit is where true performance begins.

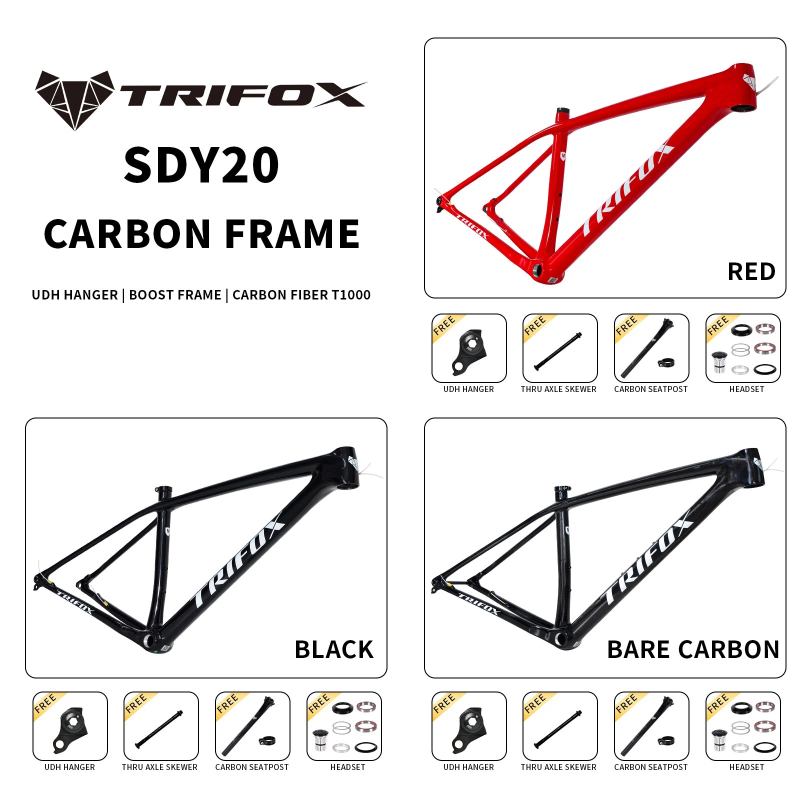

The perception that carbon fiber mountain bikes are delicate relics of road cycling has been thoroughly dismantled by modern engineering. Today's carbon hardtail frames are purpose-built to endure the punishing realities of trail riding while delivering the weight savings and performance benefits that make carbon so desirable. Understanding how frames like the Trifox SDY20 withstand trail hazards reveals the sophisticated engineering behind what appears to be a simple frame.

Modern carbon engineering begins with material science advancements. Unlike early carbon designs that used single-direction layups, current frames employ multi-directional carbon fiber weaves with varying modulus fibers. High-modulus fibers provide stiffness in critical areas like the bottom bracket and head tube, while more flexible fibers in seatstays and chainstays absorb impacts. This strategic fiber placement creates frames that are simultaneously stiff where you need power transfer and compliant where you need shock absorption.

Impact resistance represents one of carbon's most misunderstood qualities. When properly engineered, carbon frames demonstrate remarkable resilience to trail impacts. The SDY20 light hardtail frame utilizes reinforced zones at common impact points: thicker carbon layups around the downtube where rocks might strike, reinforced chainstay protectors, and impact-resistant finishes. Unlike aluminum that dents permanently or cracks catastrophically, quality carbon construction often shows visible damage before catastrophic failure, giving riders warning signs.

Fatigue resistance is another critical factor. Trail riding subjects frames to thousands of vibration cycles and stress fluctuations. Carbon's natural vibration-damping properties reduce rider fatigue, but more importantly, modern resin systems and curing processes create bonds that resist micro-cracking under repetitive stress. The 19 inch bike frame and other sizes in the SDY20 lineup undergo rigorous fatigue testing that simulates years of aggressive trail use, ensuring long-term durability.

Connection points receive special attention in trail-oriented carbon frames. The SDY20 features reinforced interfaces where components attach: extra carbon layers around the 148mm Boost axle dropouts, strengthened bottle cage mounts, and oversized bearing seats for headset durability. These reinforcements prevent the common failure points that plagued early carbon mountain bikes, ensuring the frame maintains integrity through years of component swaps and maintenance.

Frame geometry itself contributes to durability. Modern trail geometry with slack head angles and longer top tubes distributes impact forces more evenly throughout the frame structure. Rather than concentrating stress at specific points, the frame works as a complete system to absorb and dissipate trail energy. This holistic approach to stress management means frames can be lighter while actually being more durable than their predecessors.

Quality control and testing protocols separate modern carbon frames from earlier generations. Each SDY20 frame undergoes multiple inspection stages including ultrasound scanning to detect voids or inconsistencies in the carbon layup. Impact testing simulates rock strikes, fatigue testing replicates years of trail abuse, and static load testing ensures the frame can withstand forces far beyond normal riding conditions. This comprehensive testing provides the confidence needed for aggressive trail use.

To back this engineering confidence with customer assurance, Trifox provides a 2-year warranty on the SDY20 frame against defects in materials and workmanship under normal use. This warranty commitment underscores the brand's confidence in their carbon engineering and manufacturing processes. It means riders can invest in this lightweight carbon technology with peace of mind, knowing their frame is protected against unexpected manufacturing issues during years of trail enjoyment.

The result is a light hardtail frame that defies outdated perceptions. At approximately 930 grams for the frame(size S), the SDY20 offers significant weight savings over comparable aluminum frames while providing equal or better impact resistance. The weight savings translate directly to trail performance—easier climbing, quicker acceleration, and more playful handling—without sacrificing durability.

Ultimately, modern carbon engineering has evolved to meet the specific demands of trail and XC riding. Through advanced material science, strategic reinforcement, intelligent geometry, rigorous testing, and warranty support, frames like the Trifox SDY20 demonstrate that carbon can be both exceptionally lightweight and remarkably tough. For riders who want the performance benefits of carbon without compromising trail readiness, today's engineered carbon hardtails represent the perfect synthesis of technology and durability.

In the pursuit of mountain bike performance, riders often focus on marginal gains—especially weight savings. But what if the most significant upgrade isn't about shaving grams from your wheels, but about transforming the very foundation of your ride? Starting with a carbon frame and proven alloy wheels isn't a compromise; it's a strategic decision that prioritizes ride quality, durability, and real-world value.

The carbon frame is the heart of your bike's performance. A frame like the Trifox MFM200 29 inch hardtail frame delivers immediate and tangible benefits: exceptional stiffness for efficient power transfer, advanced geometry for confident handling, and carbon's natural vibration damping for reduced fatigue. These characteristics fundamentally change how the bike responds to your input and interacts with the trail. For most off-road riding, the improvements in pedaling efficiency, control, and comfort from a well-designed carbon frame far outweigh the marginal gains from ultra-lightweight wheels.

Right now, this performance-optimized combination is incredibly accessible. The Trifox MFM200 carbon hardtail frame paired with a durable WM823 alloy wheelset is available as a complete bundle for just $342 USD with free shipping. Available in multiple colors, this offer makes entering the world of carbon performance more attainable than ever.

Alloy wheels bring their own set of proven advantages that perfectly complement a carbon frame's performance:

Durability and Strength: Aluminum rims are exceptionally resilient against impacts from rocks, roots, and trail debris. They can take the punishment of aggressive trail riding without the anxiety of damaging expensive carbon rims. This durability lets you ride harder and focus on the trail, not on protecting your equipment.

Maintenance Simplicity: Alloy wheels are easier to maintain and repair. Truing, replacing spokes, and addressing dings are straightforward processes for any bike shop. For disc brake setups, alloy rims also eliminate concerns about heat-related brake performance issues that can affect some carbon rims on long descents.

Budget Allocation Wisdom: By choosing a carbon frame with alloy wheels, you allocate your budget where it makes the most difference. The savings can be invested in other critical components like a better suspension fork, upgraded drivetrain, or personalized cockpit setup—creating a more balanced, capable bike overall.

This combination creates a powerful synergy. The carbon frame provides the efficient, responsive platform, while the alloy wheels deliver reliable, durable performance. The frame's advanced engineering isn't wasted; it's fully expressed through wheels that can handle whatever the trail throws at them. For riders seeking a 29er mountain bike small frame, this approach ensures proportional handling and fit without sacrificing performance or durability.

Ultimately, this pairing is ideal for the practical performance rider: someone who logs serious miles, tackles technical terrain, and values reliability alongside performance. It's not about chasing the lightest possible build; it's about creating a bike that performs consistently, handles confidently, and withstands real-world use. The carbon frame and alloy wheels combination represents intelligent engineering meeting practical wisdom—delivering exceptional ride quality without unnecessary fragility or expense.

With the Trifox MFM200 frame and WM823 wheelset bundle, you're not just buying components; you're investing in a balanced approach to mountain bike performance. Experience how the right foundation transforms every ride, and discover why sometimes the smartest upgrade path is also the most practical one.