The question haunts every rider considering an upgrade to carbon: "Can carbon handlebars break?" It's a valid concern fueled by stories of catastrophic failure. The direct answer is yes, like any material, carbon fiber has limits and can fail if misused, damaged, or installed incorrectly. However, the more important answer lies in understanding why failures happen and how proper knowledge transforms carbon from a perceived risk into one of the strongest, most reliable components on your bike. Let's separate myth from engineering reality.

The Strength of Carbon: Stiffness, Not Brittleness

First, it's crucial to understand carbon fiber's nature. A high-quality mtb bicycle handlebar like the Trifox RHB100 is not "brittle glass." It's a composite material—thousands of ultra-strong carbon filaments embedded in a resin matrix. This construction allows it to be engineered to be exceptionally stiff and strong in specific directions (like resisting bending from your weight or steering inputs) while being remarkably lightweight. Its strength-to-weight ratio far surpasses aluminum. The perceived fragility stems from its intolerance to two specific things: impact damage and improper clamping force.

The Primary Risks: Impact and Improper Installation

Most carbon handlebar failures can be traced to a few key causes:

1. Impact Damage (The Hidden Threat): A crash or even a simple tip-over can cause a compromising impact. Unlike aluminum which might dent, carbon can suffer internal delamination—hidden cracks or separations between the carbon layers. This damage severely weakens the structure, and a bar with internal damage can fail later under normal riding loads. Always inspect your bars thoroughly after any impact.

2. Over-Torquing (The Silent Killer): This is the #1 installation error. Carbon does not yield like metal. Using the same "feel" or tools you would on an aluminum bar is dangerous. Exceeding the manufacturer's specified torque rating (typically 4-6 Nm for faceplate bolts) can crush the carbon fibers, creating stress risers that lead to cracks. A calibrated torque wrench is non-negotiable for installing carbon components.

3. Under-Torquing & Slippage: Conversely, insufficient torque can allow the bar to slip in the stem. A rider may then overtighten in a panic, leading to damage. It can also create localized stress points from movement.

4. Using the Wrong Paste: Never use grease on carbon clamp interfaces. Always use a carbon assembly paste. This specialized compound increases friction without damaging the fibers, allowing you to achieve a secure hold at the correct, lower torque.

Safe Practices for a Lifetime of Performance

Following a few golden rules ensures your mtb cycle handlebar remains safe and reliable:

* Torque, Torque, Torque: Use a quality torque wrench on every bolt. Follow the manufacturer's specs precisely (check the RHB100's documentation).

* Inspect Religiously: Before every ride, visually inspect the bar, especially around the clamp area and any potential impact points. Look for cracks, chips, or deep scratches. If in doubt, replace it.

* Handle with Care: Avoid clamping the bar in a vise or using levering tools on it during bike work. Protect it from impacts in transit or storage.

* Use Compatible Components: Ensure your stem faceplate is smooth and clean, without any sharp edges or burrs that could score the carbon surface.

Understanding the Limits and Riding with Confidence

Carbon handlebars are designed to withstand the enormous forces of riding. They are tested to standards far exceeding normal use. The Trifox RHB100, with its integrated design and monocoque carbon construction, is engineered for this purpose. The risk emerges not from the material itself, but from misuse.

By respecting the material—investing in a torque wrench, using carbon paste, and performing regular inspections—you mitigate virtually all the risk. Carbon's reward is a stiffer, more responsive, and lighter front end that improves control and reduces fatigue. The goal isn't to fear carbon, but to understand and respect its unique requirements. When treated correctly, a carbon handlebar is not a liability; it's a high-performance asset you can trust for countless miles of confident riding.

When a new carbon frame like the Trifox X16TA is released, the spec sheet tells one story: weight, geometry, and compatibility. But the true measure of a frame is written over thousands of kilometers, across varied terrain, and through every season. We’ve lived with the X16TA for months, using it as the foundation for a high-performance build. This is the long-term review that goes beyond the numbers to reveal what it’s genuinely like to ride.

First Impressions & Build Quality: A Clean Slate

Out of the box, the first thing that strikes you is the clean, purposeful aesthetic of the black frames. The finish is high-quality, with a deep, consistent gloss or sleek matte option that has proven resistant to scuffs and minor chips. As a 700c frameset, it presents a modern, balanced silhouette ready for a build. The internal cable routing ports are well-finished, and the overall mold quality shows precise carbon layup with no visible imperfections. Threads for the bottom bracket, derailleur hanger, and accessories were clean and required no chasing, speaking to careful manufacturing.

The Ride Character: Where Stiffness Meets Sensation

The spec sheet highlights a low weight, but the on-road character is defined by its excellent stiffness-to-weight ratio. From the first pedal stroke, the frame communicates efficiency. There’s an immediate, direct transfer of power that makes acceleration feel crisp and sprinting feel authoritative. The bottom bracket area is particularly rigid, with no discernible flex under high-torque efforts, whether climbing out of the saddle or launching from a stop.

However, this isn’t a harsh, unforgiving race frame. The X16TA exhibits a well-engineered level of vertical compliance. Over broken pavement and long stretches of coarse chip-seal, the frame does a remarkable job of taking the sharp edge off high-frequency vibrations. This isn’t the muted, floating feel of an endurance bike, but rather a refined firmness that keeps you connected to the road while significantly reducing fatigue in your hands and back over three or four-hour rides. It strikes a compelling balance between race-day responsiveness and all-day rideability.

Geometry & Handling: Predictable Precision

The geometry is modern and balanced. The head tube angle and fork rake yield handling that is stable at high speed yet nimble in corners. It descends with confident, planted manners, inspiring trust when leaning into switchbacks. At the same time, it’s quick to change direction, making it lively in technical, rolling terrain. This is a frame that feels equally at home in a fast paceline as it does on a solo mountain pass—it doesn’t force a single style but adapts to the rider’s input.

Durability & Long-Term Impressions

After months of use in all conditions, the frame has shown impressive resilience and reliability. The disc brake mounts have remained perfectly aligned, with no creaks or issues. The Internal cable routing, while requiring patience during the initial build, has remained silent and functional. The high-modulus carbon construction shows no signs of wear or softness, maintaining its original lively feel. It’s a frame that disappears beneath you in the best way, becoming a reliable, predictable extension of the rider that asks for little beyond routine maintenance.

The Verdict: A Frame That Grows With You

The Trifox X16TA transcends its spec sheet. It’s more than just a lightweight disc brake road bike frame; it’s a thoughtfully engineered platform that delivers a premium riding experience. It offers the stiffness a performance rider craves, tempered with a level of comfort that encourages long days in the saddle. Its versatile geometry and robust construction make it a perfect candidate for a dedicated race build, an all-rounder sportive machine, or a high-performance daily trainer. If you’re looking for a carbon road frame that provides exceptional value by blending race-ready performance with real-world refinement, the X16TA is a compelling choice that continues to impress long after the novelty has worn off.

Finding the perfect bike computer mount can be frustrating. You’ve got your Garmin, Wahoo, or Hammerhead, but with countless handlebar specs and proprietary mounts, the fear of buying the wrong thing is real. This guide cuts through the confusion with a simple, two-step verification process to ensure the Trifox SBH100 is your perfect fit, turning compatibility from a gamble into a guarantee.

Step 1: The Handlebar Interface – Will It Fit My Bike?

The first check is your handlebar. The SBH100 is designed as a universal handlebar clamp, engineered to fit the most common road and mountain bike standards. It features a forged aluminum, 4-bolt clamp mechanism with a wide adjustment range, making it compatible with standard 31.8mm and oversized 35mm diameter handlebars without needing extra shims. This sleek, low-profile clamp attaches securely to your handlebar, stem, or even an integrated cockpit’s front plate, providing a clean and versatile mounting solution.

Step 2: The Computer Interface – Will It Hold My Device?

This is the core of compatibility. The SBH100 uses a universal “quarter-turn” interface, which is the industry-standard mounting system. This means it natively supports:

* Garmin: All EDGE series computers (520, 530, 830, 1030 Plus, 1040, etc.) use the quarter-turn system. Simply click your device into place.

* Wahoo ELEMNT: Models like the BOLT, ROAM, and original ELEMNT use a different, proprietary “slide-and-lock” system. For these, you would attach your Wahoo’s original mount onto the SBH100’s GoPro-style accessory threads (using the included adapter if needed).

* Hammerhead Karoo: The Karoo 2 also uses a quarter-turn mount, making it directly compatible with the SBH100.

Your Quick-Start Compatibility Checklist:

1. My handlebar/stem diameter is: 31.8mm or 35mm? ✅ SBH100 fits both.

2. My computer brand is:

* Garmin or Hammerhead: ✅ Directly compatible with the quarter-turn mount.

* Wahoo: ✅ Compatible by attaching your Wahoo mount to the SBH100’s accessory threads.

* Bryton, Cateye, iGPSPORT: ✅ These also commonly use standard quarter-turn or GoPro-style mounts, making them compatible.

Beyond the Computer: A True Multi-Mount

The SBH100's utility extends beyond your GPS. Its integrated GoPro-compatible accessory mounts (on the top and bottom) allow you to add a bicycle light mount (for lights up to 25mm in diameter) and an action camera simultaneously. This creates a clean, centralized cockpit, eliminating the need for multiple clamps and tangled zip ties.

At Trifox, our promise is a perfect fit. The SBH100 is precision-engineered from lightweight 3K carbon fiber and forged aluminum, with each interface tested for secure, vibration-free operation. We provide clear specifications and encourage you to reach out if you have any unique setup questions. Choosing the right mount isn't just about avoiding a mistake—it’s the first step to a cleaner, more focused, and more enjoyable ride where your data is always secure and in view.

Your wheels are the engine of your bike, and the tire system you choose is the critical interface between that power and the road. For riders investing in performance carbon racing bike wheels, the decision between Clincher, Tubeless, and Tubular tire systems is fundamental. Each has distinct advantages, trade-offs, and philosophies. This guide cuts through the confusion to help you select the perfect system for your riding style, goals, and willingness to tinker.

1. Clincher: The Proven, Accessible Standard

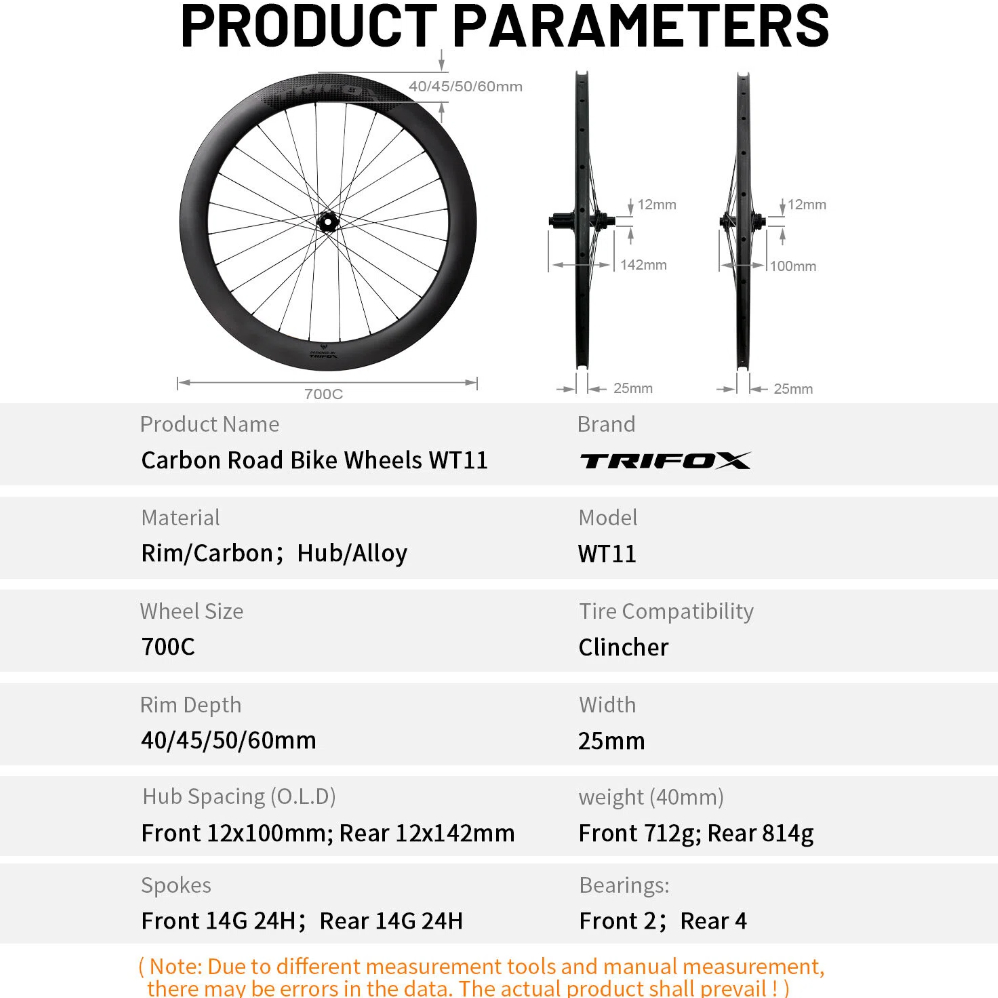

The clincher system is the most common and familiar. It uses a separate inner tube inside a tire that "clinches" onto a hooked rim bead, like the WT11 wheelset is designed for.

* Pros: Unmatched accessibility and convenience. Tires and tubes are widely available and inexpensive. Repairs are straightforward: find the puncture, patch or replace the tube, and you're rolling again. Installation is generally the easiest of the three systems, requiring only tire levers and a pump. It's the perfect, low-fuss choice for most recreational riders, commuters, and those new to high-performance road bicycle wheels.

* Cons: Requires an inner tube, which adds weight and rolling resistance. The tube is also the most vulnerable point for pinch flats (snake bites) if you hit a pothole at low pressure. At very high pressures, there's a slight risk of the tire blowing off the rim (though modern rims and tires make this extremely rare).

* Best For: Riders who prioritize ease of use, easy roadside repairs, and maximum compatibility. It's the reliable workhorse system.

2. Tubeless: The Modern Performance Benchmark

Tubeless technology, borrowed from mountain biking, has revolutionized road performance. It uses a special tire and sealed rim to create an airtight system without an inner tube. Sealant liquid inside the tire instantly plugs most small punctures.

* Pros: Superior puncture protection and ride quality. The absence of a tube eliminates pinch flats and allows you to safely run lower tire pressures (e.g., 60-80 psi vs. 90+ psi on clinchers). This dramatically increases comfort, grip, and rolling efficiency over rough surfaces. The sealant handles most small flats automatically, a huge advantage mid-ride.

* Cons: More complex setup and maintenance. Initial installation can be messy and often requires an air compressor or a high-volume pump to "seat" the tire bead onto the rim. Sealant dries out and needs replenishing every few months. Compatible tires and rims are required. Repairs for larger cuts can be more involved than simply swapping a tube.

* Best For: Performance-oriented riders seeking the best combination of comfort, grip, and flat protection for everyday training and racing. It's the ideal modern upgrade for carbon racing bike wheels.

3. Tubular: The Legendary Race-Day Specialist

Tubulars (or "sew-ups") are the oldest and most specialized system. The tire is a closed tube, stitched around an inner tube, and glued directly onto a smooth, hookless rim.

* Pros: Unbeatable ride feel and security at the limit. When properly glued, tubulars offer legendary ride quality—a supple, "connected" feel that many pros swear by. In a crash, they are less likely to roll off the rim than a clincher. They can also be ridden flat to a safe stopping point in a race.

* Cons: High cost, high complexity, and high commitment. Tires are expensive, and the gluing process is a meticulous, multi-day ritual requiring skill and patience. Repairs are difficult and time-consuming; most riders simply replace the entire tire. Swapping wheelsets is not a quick task.

* Best For: Almost exclusively competitive racers at the highest levels who have team support, prioritize the absolute pinnacle of ride quality and cornering confidence, and accept the significant hassle and cost. For the vast majority of riders, the performance gap to modern tubeless has narrowed considerably.

The Verdict: Making Your Choice

* Choose Clincher for simplicity, reliability, and hassle-free use.

* Choose Tubeless for the best all-around performance, combining flat protection, comfort, and speed for most serious riders.

* Choose Tubular only if you are a dedicated racer chasing every last percent of performance and have the support system to manage it.

For a wheelset like the disc-brake ready, carbon racing bike wheels WT11, starting with reliable clincher tires is a fantastic choice. As your confidence and demands grow, the same rims are often tubeless-ready, allowing you to easily upgrade to a tubeless system to unlock the next level of performance, making your road bicycle wheels faster and more comfortable than ever.

You've chosen your perfect machine—whether it's a versatile aluminum road bike offering incredible value or a swift beginner road bike to start your journey. You're logging miles, chasing PRs, and feeling the wind in your face. But true cycling strength isn't forged solely on the tarmac. Some of the most significant gains are made away from the saddle. Here are five powerful off-the-bike habits that will elevate your performance, boost your recovery, and help you get the most out of every ride.

1. Fuel Like an Athlete (Not Just Before the Ride)

Performance starts in the kitchen. Think of your body as a high-performance engine; premium fuel yields better results. Consistent, quality nutrition is non-negotiable. Focus on a balanced diet rich in complex carbohydrates for sustained energy (whole grains, sweet potatoes), lean protein for muscle repair and growth (chicken, fish, legumes), and healthy fats for hormone function and joint health (avocado, nuts). Don't just "carb-load" the night before a big ride; make balanced eating a daily habit. Equally important is strategic post-ride fueling. Consuming a mix of protein and carbohydrates within 30-60 minutes after a ride (a smoothie or Greek yogurt with fruit is perfect) dramatically accelerates muscle recovery, reduces soreness, and prepares your body for the next effort. Hydration is a constant process, not just a ride-day task. Drinking water consistently throughout the day ensures you start every ride optimally hydrated.

2. Prioritize Sleep as Your #1 Recovery Tool

Sleep is not downtime; it's prime-time for repair and adaptation. During deep sleep, your body releases growth hormone, repairs muscle micro-tears from training, consolidates motor skills (making your pedal stroke more efficient), and recharges your central nervous system. Consistently getting 7-9 hours of quality sleep is arguably the most effective performance enhancer available. Poor sleep increases cortisol (a stress hormone), impairs recovery, reduces power output, and clouds judgment on the bike. Establish a regular sleep schedule, create a dark and cool sleeping environment, and limit screen time before bed. View sleep as a critical part of your training plan, not an afterthought.

3. Build a Foundation with Functional Strength Training

Cycling develops powerful leg muscles but can neglect the stabilizing core, back, and upper body muscles that are essential for efficient power transfer and injury prevention. Just 2-3 sessions per week of functional strength training can yield remarkable benefits. Focus on compound movements that build full-body resilience: squats and lunges for leg strength, deadlifts and rows for a powerful back and posterior chain, and planks and anti-rotation exercises for a rock-solid core. A stronger core prevents energy-wasting upper body movement, allowing you to channel more power into the pedals. A stronger body is also a more durable body, better able to handle long hours in the saddle and resist overuse injuries.

4. Commit to Consistent Mobility and Flexibility Work

Cycling is a repetitive motion that can lead to tight hips, hamstrings, and a rounded posture. Dedicated mobility work counteracts this, improving your range of motion on the bike. This isn't about extreme contortion; it's about maintaining the functional mobility needed for an aerodynamic and powerful position. Regular dynamic stretching before a ride (leg swings, hip circles) prepares your muscles. Post-ride static stretching and foam rolling for key areas like quads, hip flexors, IT bands, and glutes help release tension, improve blood flow, and speed recovery. Better mobility translates directly to a more comfortable, sustainable, and powerful riding position.

5. Embrace Active Recovery and Listen to Your Body

More is not always better. Intentional recovery days are when your body adapts and gets stronger. Active recovery—a gentle walk, a casual spin, or light yoga—promotes blood flow to sore muscles without adding stress, helping to clear metabolic waste. Crucially, learn to listen to your body's signals. Persistent fatigue, irritability, trouble sleeping, or a plateau in performance can be signs of overreaching. Having the discipline to take an extra rest day or swap a hard interval session for a zone 1 recovery ride is a sign of a smart athlete. This prevents burnout and injury, ensuring you can train consistently over the long term.

By integrating these five pillars into your routine, you stop just riding your bike and start truly training your body. The synergy between your time on a capable aluminum road bike and these intelligent off-bike habits will unlock new levels of speed, endurance, and enjoyment. Performance isn't just about the miles you put in; it's about how holistically you prepare your body to absorb and benefit from them.

The sight of a clean, integrated cockpit is a thing of beauty—a seamless blend of form and function that promises aerodynamic gains and a clutter-free look. However, for many riders and mechanics, the thought of threading brake hoses and shift cables through a one-piece carbon mtb bicycle handlebar has been a source of dread, synonymous with hours of frustration, fishing with guide wires, and skinned knuckles. It doesn't have to be this way. The Trifox RHB600 is engineered from the ground up with a simple philosophy: performance should not come at the cost of serviceability. It proves that with thoughtful design, installing cables in a fully integrated bar can be a logical, even intuitive, process.

Engineered Pathways, Not Just Holes

The journey to an easy installation begins before you even pick up a cable. The RHB600 features dedicated, oversized internal channels that are molded directly into the carbon structure during manufacture. Unlike retrofitted holes or tight, winding paths, these channels are designed with a consistent diameter and smooth internal finish. This isn't just an empty space; it's a precisely engineered guideway that naturally directs cables and hoses from the stem entry point to their exits at the bar ends and lever clamps. The path is clear, logical, and free of sharp edges or unnecessary turns that cause snagging.

Clear Access Points

Ease of access is critical. The RHB600 is designed with large, clearly defined entry and exit ports. The port at the stem clamp area is generously sized, allowing you to easily see and feed cables into the main channel. More importantly, the exit ports at the lever mounting areas are not just small holes, but are shaped to provide a clear, open path for the housing to emerge cleanly. This thoughtful opening eliminates the frustrating "blind fishing" exercise often associated with integrated bicycle bars, where you're trying to maneuver a flexible housing through a tiny, unseen opening.

Tool-Friendly Design

A truly user-friendly design doesn't stop at guiding the cable; it also considers how you get it there. The internal channels of the RHB600 are designed to be compatible with standard installation tools and techniques. Using a simple, flexible guide wire or a mechanic's cable becomes a straightforward task. You can feed the wire through one port and confidently pull it out the other, knowing the smooth channel will guide it without catching. Once the guide is through, attaching your brake hose or shift housing and pulling it back through is a simple, one-person operation. This design respects the mechanic's time and skill, turning a complex job into a series of simple, logical steps.

Clean Finishing Details

The final touch is in the finishing details. The RHB600 includes specially designed, removable rubber port covers and grommets. Once your cables are installed, these covers snap neatly into place, creating a clean, sealed, and professional finish that looks factory-perfect. They protect the entry points from dirt and moisture without requiring messy sealants or adhesives, making future maintenance or cable replacement just as simple.

In summary, the Trifox RHB600 redefines what an integrated cockpit can be. By prioritizing intelligent features like oversized, smooth channels, large access ports, and tool-friendly design, it removes the traditional pain points of internal routing. It demonstrates that the pinnacle of carbon integrated handlebar design isn't just about achieving a sleek look or low weight—it's about creating a component that is both high-performance and genuinely practical to live with. The RHB600 doesn't just make cable installation possible; it makes it intuitive, transforming a daunting task into a satisfying part of building your dream bike.

TRIFOX X11 Road Bike Frame Launched | full internal. Ultralight · 700 * 35C

The pursuit of the perfect road bike frame is a relentless chase for harmony: featherweight agility paired with unshakable stiffness, aerodynamic efficiency balanced with real-world versatility, and timeless aesthetics integrated with future-proof technology. This pursuit has a new benchmark. Trifox is proud to unveil the X11—a next-generation road cycle frame that doesn't ask you to choose, but masterfully delivers on all fronts. It's engineered not just to be ridden, but to redefine your expectations of speed, comfort, and precision.

At the core of the X11's philosophy is an uncompromising commitment to ultralight performance. Meticulously crafted from our highest-grade T800 and T1000 carbon fiber, the frame achieves a staggering sub-900-gram weight (size dependent) through advanced monocoque molding and strategic material layup. This isn't weight saved for its own sake; it's mass meticulously removed to create a bike that responds to the slightest input, accelerates with explosive urgency, and makes every climb feel like an opportunity. It's a pure, unadulterated connection to the road.

The X11 embraces a fully integrated, clean-sheet design. Every cable and hose is routed internally through the headset and frame, creating a flawlessly sleek silhouette that slices through the air. This isn't just about aesthetics; it's about eliminating drag and presenting a unified front against the wind. The engineering behind this is sophisticated, featuring internal guides and reinforced entry points to ensure smooth installation and long-term reliability, proving that clean looks and robust function are not mutually exclusive.

This frame is built for the modern era of road cycling. It discards outdated standards in favor of reliable, high-performance technology:

* Unified Derailleur Hanger (UDH): Embracing the industry-standard UDH future-proofs your investment. It ensures wide compatibility with current and future drivetrain innovations and simplifies maintenance with an easily replaceable, universal hanger.

* T47 Threaded Bottom Bracket: At its heart lies a T47 threaded shell, offering the creak-free security of threads with the increased stiffness and bearing support of a oversized design. It's the perfect blend of reliability and performance.

* Expanded Tire Clearance: With ample room for 700x35c tires, the X11 shatters the old boundaries of a race bike. It invites you to fit robust rubber for sublime comfort on rough pavement, confident exploration on smooth gravel, or simply to run lower pressures for enhanced grip and ride quality—all without sacrificing its racing pedigree.

The X11's geometry is the final piece of the puzzle. Developed with input from dedicated riders, it strikes an ideal balance between a responsive, agile race feel and stable, confident handling at high speeds. This precise calibration makes it equally at home attacking in a local criterium, carving through mountain descents, or powering through a long solo breakaway. It's a frame that inspires confidence to push limits.

For the racer seeking every competitive edge, the X11's design and geometry are conceived with UCI road compliance in mind, making it a potent weapon for sanctioned competition. But its appeal is far broader. It is the ultimate foundation for the discerning enthusiast who demands a bike that is breathtakingly light, technically sophisticated, and adaptable enough for any road ahead. The Trifox X11 isn't just a new frame; it's a new standard for what a modern, ultralight road cycle frame can be.

Why Our Internally Routed Frame Rides Stiffer and Lighter

It’s a brilliant question: “If you’re drilling holes in the frame for cables, doesn’t that make it weaker?” It’s a completely reasonable assumption. In the world of modern carbon fiber engineering, however, the answer is a definitive "no." The key is that in a high-performance frame like the Trifox SDY21, these internal channels are not an afterthought or a destructive cut into a finished structure. Instead, they are precisely calculated engineering features integrated from the very first stages of Finite Element Analysis (FEA). Our goal is not to choose between beauty and performance, but to engineer a solution that wins on all fronts: superior aesthetics, enhanced rigidity, and reduced weight.

Localized Reinforcement & Structural Design: Think of it like the engineering of a modern building. A window isn't just a hole in a wall; it’s surrounded by a reinforced lintel that redistributes load. Similarly, around every critical entry and exit point in the SDY21 frame—especially the head tube—we apply additional carbon fiber layers and localized reinforcement. We use strategic patches of higher-modulus T800 carbon in these high-stress areas. This targeted reinforcement ensures the structure is actually stronger at its most vulnerable points, turning potential weaknesses into fortified zones. Furthermore, the internal channels themselves are designed with specific, stiffness-enhancing shapes, effectively becoming integrated structural elements rather than simple voids.

Holistic Engineering and Structural Integrity: A high-performance carbon frame is not a collection of tubes; it is a singular, unified monocoque structure. The rigidity comes from the entire shape and the continuous carbon fiber layup. By designing the internal routing paths as an integral part of this holistic structure from the start, we can model and mitigate any localized stress concentration. The frame’s overall stiffness and strength are engineered to meet or exceed rigorous international standards (such as ISO 4210) with the routing channels fully accounted for. This means the SDY21’s structural integrity is validated as a complete system, proving that intelligent design can incorporate functionality without sacrificing robustness.

The proof is in the performance. The Trifox SDY21 isn’t just about a clean look. This rigid frame mtb achieves an exceptional stiffness-to-weight ratio. The compact 19 inch mtb frame size weighs in at just 1075 grams, a benchmark that rivals many premium hardtails. This staggering lightness is achieved without sacrificing the direct, responsive feel that serious XC and trail riders demand. The clean internal routing eliminates external cable drag and snag points, contributing to a more aerodynamic and maintenance-friendly package.

Ultimately, a superior full-internal routing design like that of the SDY21 represents a higher level of engineering sophistication. It moves beyond the old compromise. The result is a frame that is not only sleeker and easier to maintain but also stiffer and lighter—a true triathlon of benefits that elevates your ride. It’s engineering that works smarter, delivering a lightweight hardtail frame where every element, including the cable paths, contributes to the ultimate goal: a faster, more efficient, and more connected ride on the trail.

In the world of mountain biking, performance has traditionally come with a premium price tag—until now. The TRIFOX Pioneer shatters this paradigm by delivering a complete carbon fiber fully suspended mountain bike with a Shimano R6100 groupset for just $1399. This isn't a stripped-down compromise; it's a thoughtfully engineered trail machine designed specifically for mtb cross country xc, daily trail riding, and adventure-seeking cyclists who demand quality without breaking the bank.

At the heart of the Pioneer is its full carbon frame, a feature rarely found at this price point. Carbon fiber construction offers more than just weight savings; it provides the perfect balance of stiffness for efficient pedaling and compliance for trail comfort. The frame's modern trail geometry—with a slack head angle for descending confidence and balanced chainstays for climbing stability—creates a versatile platform that handles everything from flowy singletrack to technical root sections. Available in multiple sizes and colors, the Pioneer ensures both proper fit and personal expression.

The suspension system is precisely calibrated for its intended use. With 140mm of travel front and rear, this fully suspended mountain bike provides enough cushion to smooth out trail chatter and handle moderate obstacles without the weight and inefficiency of longer-travel enduro rigs. The suspension kinematics are optimized for pedaling efficiency, meaning you get traction and comfort when you need it without excessive bob on climbs. For mtb cross country xc enthusiasts and weekend trail riders, this "just right" travel hits the sweet spot between capability and efficiency.

Component selection demonstrates intelligent prioritization. The Shimano R6100 1x12 drivetrain delivers reliable, precise shifting across a wide gear range—essential for varied terrain where maintaining momentum is key. Quality hydraulic disc brakes provide consistent stopping power in all conditions, while tubeless-ready wheels offer the option for lower tire pressures and improved traction. Every component choice reflects an understanding of what matters most for trail performance: reliability, functionality, and real-world durability.

What makes the $1399 price truly remarkable is the holistic integration of these elements. This isn't simply a collection of parts bolted together; it's a cohesive system where the carbon frame, suspension tuning, and component selection work in concert. The result is a bike that feels greater than the sum of its parts—responsive on climbs, composed on descents, and agile through technical sections. For riders moving up from entry-level hardtails or aluminum full-suspension bikes, the difference in ride quality is immediately apparent.

The Pioneer's versatility extends beyond pure trail riding. Its efficient pedaling platform makes it suitable for longer adventures, while its capable handling inspires confidence on more challenging terrain. It's the ideal "one bike" solution for riders who don't specialize in extreme downhill or endurance racing but want a competent, enjoyable companion for their local trails, weekend group rides, and spontaneous adventures.

It's important to note the Pioneer's design boundaries. With 140mm travel and trail-oriented geometry, it's not intended for bike park downhill runs or enduro racing. This clarity of purpose is actually a strength—by focusing specifically on trail and XC riding, TRIFOX has optimized every aspect of the bike for that experience without unnecessary compromises or costs.

In an industry where carbon full-suspension bikes often start at twice this price, the TRIFOX Pioneer represents a fundamental shift. It proves that advanced materials and quality components don't have to be reserved for elite budgets. For $1399, you're not getting a "budget bike"—you're getting a thoughtfully engineered fully suspended mountain bike that delivers genuine carbon performance, capable suspension, and reliable shifting. The Pioneer isn't just affordable; it's a smart investment in trail enjoyment, redefining what's possible at this price point and inviting more riders to experience the benefits of modern carbon mountain bike technology.