The quest for the perfect road bike frame is an endless pursuit of balance—stiffness versus comfort, weight versus durability, and agility versus stability. It often feels like a compromise. What if the next evolution wasn't about choosing one over the other, but about achieving it all in one meticulously engineered package? The wait is almost over. We are thrilled to offer a first glimpse at a project that redefines these boundaries: the upcoming X11. This isn't just another frame; it's a statement of intent, engineered from the ground up to be the lightest, most versatile, and technologically advanced platform in its class.

A New Benchmark in Weight and Performance

At the heart of the X11 lies a stunning achievement in material science and layup engineering. Crafted from advanced framed carbon, the size XS frame tips the scales at a mere 890 grams (with a +/-20g tolerance). This isn't just a lightweight frame; it represents the pinnacle of our manufacturing, where every gram is scrutinized and every layer of carbon is strategically placed to optimize the strength-to-weight ratio. This extreme lightness translates directly to the ride: explosive acceleration, effortless climbing, and a lively, connected feel that makes every watt count. For riders seeking a 54cm frame or other sizes, this philosophy of minimal weight and maximal performance carries through the entire size range.

Engineered for the Modern Road and Beyond

The X11 is built for the way we ride today—fast on the road, confident on rough pavement, and ready for adventure. It discards outdated standards in favor of modern, reliable, and versatile technologies:

* Uncompromising Stopping Power: Full disc brake integration with flat mounts ensures consistent, powerful braking in all conditions, from alpine descents to wet commutes.

* Future-Proof Compatibility: At its core is a T47 threaded bottom bracket. This oversized standard offers the creak-free reliability of threads with the increased stiffness and bearing life of a larger shell, ensuring compatibility with a wide range of cranksets now and in the future.

* The Universal Solution: Embracing the UDH (Universal Derailleur Hanger) is a commitment to simplicity and sustainability. This industry-standard hanger is widely available, making replacements after a crash quick and inexpensive, and future-proofing the frame for upcoming drivetrain innovations.

Versatility as a Core Feature

True performance isn't limited to smooth tarmac. The X11's design acknowledges the growing demand for one-bike versatility. With clearance for tires up to 700x35c, it seamlessly bridges the gap between a razor-sharp road machine and a capable gravel explorer. This allows you to fit robust, high-volume tires for comfort on long rides, traction on light gravel, or confidence in imperfect weather, all without switching bikes.

The Trifox frame engineering philosophy has always been about delivering exceptional value through direct design and manufacturing. The X11 is the culmination of this approach. It takes the lessons learned from countless miles on the road and distills them into a frame that is as intelligent as it is beautiful.

We are on the cusp of revealing the complete picture: the full geometry, the aesthetic details, and the final specifications. The X11 is more than a frame; it's the foundation for your next dream build—a platform that is staggeringly light, technically sophisticated, and ready for any challenge you throw at it.

Stay tuned. The revelation is coming soon.

At first glance, a performance carbon saddle like the Trifox CS100 can seem intimidating. Its sleek, minimalist appearance and rigid full-carbon fiber construction stand in stark contrast to the plush, padded saddles many are used to. It's perfectly reasonable to wonder: "Will this be comfortable?" The answer lies in a fundamental shift in thinking. A performance cycling saddle is not designed to provide comfort through cushioning that you sink into. Instead, its core philosophy is support over softness. It aims to provide a stable, precise platform for your sit bones, freeing your legs to focus purely on pedaling power and efficiency. This isn't about passive comfort; it's about active, empowering performance.

Let's demystify what it really means to "require" a good position to use such a saddle effectively.

* It's About Stability, Not Core Strength: The requirement for good form isn't about needing pro-level fitness. It's about the ability to maintain a stable pelvis and avoid rocking side-to-side on the saddle. A firm, supportive platform like the CS100 actually aids this by giving your sit bones a clear, unwavering point of contact, helping you find and hold an efficient position more naturally.

* Precision Setup is a Feature, Not a Bug: Yes, achieving optimal comfort requires more precise saddle angle and fore/aft positioning. However, view this as the saddle's greatest tuning advantage. Because it provides immediate, unambiguous feedback, it acts as a precise micro-adjustment tool. Small changes yield noticeable differences, allowing you (or a bike fitter) to dial in your perfect position faster and more accurately than with a vague, forgiving saddle.

So, who is this type of bicycle saddle truly for? It’s an excellent match for the serious enthusiast whose rides regularly exceed 1.5 to 2 hours, who is chasing speed or efficiency gains, and who understands that long-distance comfort is achieved through proper support and fit—not by simply adding more padding. It’s for the rider willing to invest time in optimizing their bike setup. Conversely, it may not be the ideal choice for purely casual, upright riders or those who prefer a more relaxed, static seating position on the bike.

If the potential for a lighter, more efficient, and precisely supportive ride appeals to you, your logical next step is clear: prioritize a professional bike fit. A proper fit ensures your overall bike geometry and riding posture are correct. With that solid foundation established, you can then explore whether a performance carbon saddle is the right final piece of your setup puzzle. The Trifox CS100, with its sub-106g weight, ergonomic nose design to prevent numbness, and central vent for airflow, exemplifies this performance-oriented approach, offering a clear upgrade path for riders ready to make the leap.

We've all been there: a handlebar cluttered with multiple mounts, zip ties, and dangling accessories. The traditional "stack-and-clamp" approach creates a messy cockpit, adds unnecessary weight and drag, and compromises security. This tangle of brackets not only looks unprofessional but can also lead to vibrations that damage your expensive electronics. The solution? A unified mounting system designed from the ground up to organize, secure, and streamline—introducing the Trifox SBH100 carbon mount.

The Core Structure: A Secure Foundation

At the heart of the system is a precision-engineered carbon fiber base that serves as your primary mounting platform. It features a standard Garmin/Bryton-style quarter-turn mount as its centerpiece, providing rock-solid attachment for your cycling computer mount. No more wobbly brackets or alignment issues. The carbon construction offers exceptional stiffness-to-weight ratio, ensuring your valuable computer stays precisely where you need it, with minimal vibration transmission even on rough trails.

Modular Expansion: Build Your Perfect Setup

The true innovation lies in the SBH100's modular design. The mount isn't just for your computer—it's a platform for your entire cockpit ecosystem. Through strategically placed accessory ports and compatible adapters, you can seamlessly integrate:

* Action Camera: Dedicated GoPro-compatible mounts position your camera perfectly for capturing trail action or road rides

* Bike Lights: Integrated light mounts keep your illumination centered and secure without bulky separate brackets

* Additional Accessories: Space for small tools, emergency whistles, or even secondary navigation devices

This modular approach means you're not buying multiple separate mounts; you're investing in a system that grows with your needs.

The Clean Integration Secret

What separates the SBH100 from makeshift solutions is its integrated design philosophy. All components share a unified aesthetic with clean lines and minimal hardware. The system includes clever cable management features like internal routing channels for light cables, keeping everything tidy and protected. The result isn't a collection of parts—it's a cohesive, factory-installed appearance that looks professional and performs reliably.

Scenario-Based Configuration Recommendations

Your ideal setup depends on your riding style. Here are our recommendations:

Road Racing & Fast Group Rides:

Computer + Aerodynamic Tail Light

Keep your cockpit clean and aerodynamic while maintaining essential visibility. The low-profile design minimizes drag while keeping your computer in optimal viewing position.

Mountain & Trail Adventure:

Computer + Powerful Headlight + Action Camera

Handle technical terrain with confidence. The secure mounting ensures your light illuminates the trail ahead while your camera captures every moment—no more worrying about accessories shaking loose on rough descents.

Gravel & Long-Distance Touring:

Computer + Navigation Phone Mount + Dual Lights

For epic adventures where reliability is paramount. Keep navigation accessible, maintain visibility in changing conditions, and have backup lighting—all organized in one robust system.

Commuting & Urban Riding:

Computer + Bright Commuter Light + Secondary Device Mount

Navigate city streets safely with optimal device positioning and maximum visibility to other road users. The secure mounting prevents theft of accessories during quick stops.

The Ultimate Value: Space Management Mastery

The Trifox SBH100 isn't just another bicycle garmin mount—it's a complete cockpit management solution. Its value extends beyond the physical product to the time, frustration, and worry it saves. No more pre-ride adjustments of multiple loose brackets. No more anxiety about whether your camera will survive the next descent. No more tangled cables distracting from your ride.

By consolidating your essential accessories into one secure, aerodynamic platform, the SBH100 transforms your handlebar from a cluttered workspace into a clean, functional command center. It represents the evolution of bike mounting from afterthought to integrated system—where every component has its place, every connection is secure, and every ride begins with confidence rather than compromise.

Whether you're chasing personal bests on the road, exploring new trails, or simply enjoying your daily commute, the right mounting system enhances your experience by removing distractions and keeping your focus where it belongs: on the ride itself. The SBH100 proves that sometimes the most significant upgrades aren't the components themselves, but how elegantly they work together.

Let's be honest: the sight of a modern internal cable handlebar can be intimidating. The sleek, unbroken lines promise aerodynamic gains and a clean look, but they also whisper of complicated installations and future maintenance headaches. These concerns are valid, but they're also largely based on outdated experiences. Today's integrated cockpits, like the Trifox RHB600, are designed with the user in mind, transforming installation from a daunting task into a straightforward, confidence-building process.

The key to success lies in understanding the systematic approach to installation. First and foremost: Torque and Tools Matter. This cannot be overstated. Carbon components require precise installation. For the RHB600 carbon mtb bar, we specify exact torque values for the stem faceplate bolts (typically 4-6 Nm) and the top cap pre-load bolt (typically 2-4 Nm). Using a quality torque wrench is not optional; it's essential to prevent slipping, overtightening, and potential damage. Always apply a thin layer of carbon assembly paste to the handlebar clamp area and the steerer tube to ensure a secure, non-slip interface. This simple step ensures your position stays put without damaging the carbon fibers.

The Bolt Layout Design of the stem section is engineered for ease and security. The RHB600 features a 4-bolt front-loading faceplate. This design allows you to easily place the handlebar, set your desired angle, and then evenly tighten the bolts in a cross pattern. This method ensures uniform pressure distribution, eliminating gaps or uneven clamping force that could lead to stress points or slippage. The included top cap and spacers provide the necessary flexibility to fine-tune your stack height before finalizing the headset preload, making initial setup intuitive.

Now, let's tackle the elephant in the room: Integrated Routing Simplified. The RHB600 is designed to make cable and hose installation as painless as possible. Key features facilitate this:

* Large, Accessible Ports: The entry and exit ports are generously sized, making initial threading much easier.

* Smooth Internal Channels: The interior of the carbon bar is molded with smooth guides to prevent hoses from snagging.

* Removable Port Covers: The sleek rubber grommets or port covers can be easily removed for routing and just as easily popped back in for a clean finish.

Think of it this way: We've done the hard part. The complex internal channels are precision-molded into the carbon structure during manufacturing. Your task is simply to guide the cables and hoses through a pre-designed, optimized path. Start by feeding a mechanic's cable or a dedicated guide wire through from the stem end, attach your housing, and pull it through. A little patience and the right technique make the process manageable for any home mechanic.

This focus on user-friendly design extends from installation to long-term Serviceability. The fully integrated design isn't a maintenance trap. Once set up, the system is incredibly reliable. Should you ever need to replace a cable or hose, the process is simply the initial installation in reverse. The design ensures that routine maintenance remains accessible.

Ultimately, the RHB600's installation process is a direct reflection of a user-centric design philosophy. By providing clear guidelines, thoughtful engineering in the bolt layout, and simplifying the internal routing path, we've turned a potential barrier into an opportunity. Following these steps doesn't just secure your components; it builds your confidence in the product. A proper installation is the first step in building trust with your new carbon mtb bar, transforming initial apprehension into the satisfying certainty of a secure, professional-grade setup that's ready for the trail.

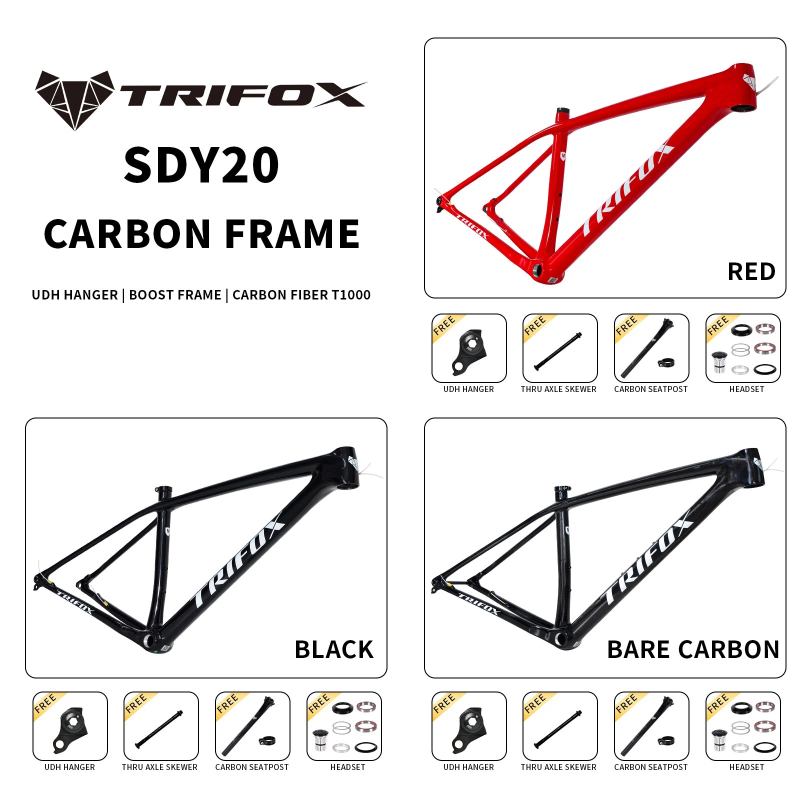

The perception that carbon fiber mountain bikes are delicate relics of road cycling has been thoroughly dismantled by modern engineering. Today's carbon hardtail frames are purpose-built to endure the punishing realities of trail riding while delivering the weight savings and performance benefits that make carbon so desirable. Understanding how frames like the Trifox SDY20 withstand trail hazards reveals the sophisticated engineering behind what appears to be a simple frame.

Modern carbon engineering begins with material science advancements. Unlike early carbon designs that used single-direction layups, current frames employ multi-directional carbon fiber weaves with varying modulus fibers. High-modulus fibers provide stiffness in critical areas like the bottom bracket and head tube, while more flexible fibers in seatstays and chainstays absorb impacts. This strategic fiber placement creates frames that are simultaneously stiff where you need power transfer and compliant where you need shock absorption.

Impact resistance represents one of carbon's most misunderstood qualities. When properly engineered, carbon frames demonstrate remarkable resilience to trail impacts. The SDY20 light hardtail frame utilizes reinforced zones at common impact points: thicker carbon layups around the downtube where rocks might strike, reinforced chainstay protectors, and impact-resistant finishes. Unlike aluminum that dents permanently or cracks catastrophically, quality carbon construction often shows visible damage before catastrophic failure, giving riders warning signs.

Fatigue resistance is another critical factor. Trail riding subjects frames to thousands of vibration cycles and stress fluctuations. Carbon's natural vibration-damping properties reduce rider fatigue, but more importantly, modern resin systems and curing processes create bonds that resist micro-cracking under repetitive stress. The 19 inch bike frame and other sizes in the SDY20 lineup undergo rigorous fatigue testing that simulates years of aggressive trail use, ensuring long-term durability.

Connection points receive special attention in trail-oriented carbon frames. The SDY20 features reinforced interfaces where components attach: extra carbon layers around the 148mm Boost axle dropouts, strengthened bottle cage mounts, and oversized bearing seats for headset durability. These reinforcements prevent the common failure points that plagued early carbon mountain bikes, ensuring the frame maintains integrity through years of component swaps and maintenance.

Frame geometry itself contributes to durability. Modern trail geometry with slack head angles and longer top tubes distributes impact forces more evenly throughout the frame structure. Rather than concentrating stress at specific points, the frame works as a complete system to absorb and dissipate trail energy. This holistic approach to stress management means frames can be lighter while actually being more durable than their predecessors.

Quality control and testing protocols separate modern carbon frames from earlier generations. Each SDY20 frame undergoes multiple inspection stages including ultrasound scanning to detect voids or inconsistencies in the carbon layup. Impact testing simulates rock strikes, fatigue testing replicates years of trail abuse, and static load testing ensures the frame can withstand forces far beyond normal riding conditions. This comprehensive testing provides the confidence needed for aggressive trail use.

To back this engineering confidence with customer assurance, Trifox provides a 2-year warranty on the SDY20 frame against defects in materials and workmanship under normal use. This warranty commitment underscores the brand's confidence in their carbon engineering and manufacturing processes. It means riders can invest in this lightweight carbon technology with peace of mind, knowing their frame is protected against unexpected manufacturing issues during years of trail enjoyment.

The result is a light hardtail frame that defies outdated perceptions. At approximately 930 grams for the frame(size S), the SDY20 offers significant weight savings over comparable aluminum frames while providing equal or better impact resistance. The weight savings translate directly to trail performance—easier climbing, quicker acceleration, and more playful handling—without sacrificing durability.

Ultimately, modern carbon engineering has evolved to meet the specific demands of trail and XC riding. Through advanced material science, strategic reinforcement, intelligent geometry, rigorous testing, and warranty support, frames like the Trifox SDY20 demonstrate that carbon can be both exceptionally lightweight and remarkably tough. For riders who want the performance benefits of carbon without compromising trail readiness, today's engineered carbon hardtails represent the perfect synthesis of technology and durability.

In mountain biking, individual component quality matters—but true performance emerges from how these parts work together. When you pair a premium carbon frame with a purpose-matched carbon fork, you unlock a level of synergy that transforms your entire ride. The combination of Trifox's SDY21 carbon hardtail frame and TMK200 rigid mtb fork 29 creates a unified system where stiffness, weight savings, and responsiveness multiply rather than simply add.

The foundation of this partnership is material harmony. Both the SDY21 frame and TMK200 fork are constructed from high-modulus unidirectional carbon fiber, using compatible resin systems and layup techniques. This shared material DNA ensures consistent flex characteristics and vibration damping throughout the front triangle. When frame and fork speak the same structural language, energy transfer becomes incredibly efficient. Every pedal stroke propels you forward with minimal loss, while trail vibrations are absorbed uniformly, reducing fatigue.

Geometry alignment is equally critical. The SDY21 frame is designed around modern trail metrics—a slack head angle, short chainstays, and optimized front-center measurement. The TMK200 fork complements this with precisely calculated offset and axle-to-crown length. Together, they create handling that's both stable at speed and nimble in corners. This isn't a generic fork bolted to any frame; it's a calibrated pairing where steering precision feels intuitive and predictable.

Weight optimization reaches its peak in this combo. The SDY21 frame utilizes strategic carbon layering to reinforce high-stress zones while trimming material elsewhere. Similarly, the TMK200 is engineered as one of the lightest mountain bike fork options in its category. When combined, the total weight savings at the front end significantly improves maneuverability. The bike feels more willing to change direction, easier to loft over obstacles, and generally more lively on the trail. This synergy makes the whole bike feel lighter than the sum of its parts.

Stiffness synchronization creates another performance multiplier. A stiff frame paired with a flexible fork (or vice versa) creates handling inconsistencies. With the SDY21 and TMK200, both components share similar torsional and lateral rigidity. This means when you lean into a corner or power through a rock garden, the front and rear of the bike respond as one cohesive unit. There's no lag or disconnection—just immediate, faithful tracking that builds rider confidence.

The practical benefits extend to assembly and maintenance. Designed as a matched system, the fork's tapered steerer integrates seamlessly with the frame's head tube. The Boost spacing aligns perfectly, and brake routing follows complementary paths. This compatibility eliminates installation headaches and ensures optimal performance from day one. Additionally, the shared aesthetic—clean carbon textures and minimalist branding—creates a visually unified machine that looks as fast as it rides.

Choosing a frame and fork as an integrated system, like the Trifox SDY21 and TMK200 bundle, represents a smarter approach than mixing and matching components. You're not just buying two separate parts; you're investing in a harmonious relationship engineered from the ground up. The result is a mountain bike that handles with a rare balance of efficiency, control, and pure fun. In the equation of performance, synergy is the ultimate multiplier, transforming capable components into an extraordinary complete bike.

In the world of mountain bike upgrades, few components transform a ride like a high-quality carbon fork. The TRIFOX TMK200 represents a breakthrough in self-developed carbon technology, offering riders a premium rigid mtb fork that balances performance, weight, and value in ways that challenge established brands.

At the heart of the TMK200 is its full-carbon construction. Unlike composite designs that blend materials, this carbon fork is engineered from premium unidirectional carbon fiber throughout. The result is a remarkably lightweight structure—typically weighing around 500 grams—that doesn't compromise on durability or stiffness. For riders seeking to reduce front-end weight without sacrificing control, this represents a significant upgrade over traditional aluminum or steel rigid forks.

The TMK200 is specifically designed as a rigid 29er fork, optimized for modern trail geometry. With a tapered steerer tube (1.5" to 1.125") and Boost 110mm axle spacing, it provides exceptional steering precision and wheel stiffness. This design minimizes flex during aggressive cornering and technical descents, giving riders more confidence through challenging terrain. The fork's offset has been carefully calculated to maintain balanced handling characteristics, preserving the bike's intended geometry while improving responsiveness.

Disc brake compatibility is another standout feature. The TMK200 includes post-mount disc brake fittings that accommodate both flat-mount and post-mount calipers, offering versatility for different brake systems. This ensures powerful, consistent braking performance in all conditions—a critical consideration for mountain biking where control is paramount. The fork legs are shaped to provide ample tire clearance for up to 29x3.0" tires, accommodating the trend toward wider rubber for improved traction.

What truly sets this bicycle carbon fork apart is TRIFOX's complete control over the manufacturing process. From material selection to layup patterns and curing, every aspect is managed in-house. This vertical integration allows for stringent quality control and cost efficiency, resulting in a product that delivers premium performance at a remarkably accessible price point. The finish quality reflects this attention to detail, with smooth carbon surfaces and clean machining on all interfaces.

Installation and compatibility are straightforward. The TMK200 works with most modern mountain bike frames designed for rigid forks, and the included compression plug ensures secure steering assembly. Riders will appreciate the immediate difference in trail feedback—carbon's natural vibration damping reduces hand fatigue without isolating the rider from essential terrain information. This creates a more connected, controlled riding experience that enhances both technical trail riding and long-distance endurance.

In terms of value proposition, the TRIFOX TMK200 challenges the notion that high-performance carbon components must carry premium price tags. By eliminating brand markup and middleman costs, TRIFOX delivers a rigid mtb fork that competes with options costing significantly more. Whether you're building up a new trail bike, upgrading an existing hardtail, or seeking the reliability of a rigid fork for bikepacking adventures, the TMK200 represents intelligent engineering focused on real-world riding benefits.

The TRIFOX TMK200 carbon mountain bike fork demonstrates how thoughtful design and direct manufacturing can redefine performance benchmarks. It's not merely a lighter alternative to metal forks; it's a precision tool that enhances control, efficiency, and riding pleasure. For riders who value both performance and practical value, this fork offers a compelling upgrade path that elevates the entire mountain biking experience.

Every cyclist knows the frustration: hitting a rough patch of trail or a pothole on the road, only to hear the dreaded *clatter* of a water bottle bouncing onto the asphalt. A lost bottle means lost hydration and a frustrating stop. This common failure point is why designing a carbon fiber bottle cage is a precise exercise in balancing two opposing forces: maximum grip and minimum weight.

The quest for the lightest bottle cage often leads to minimalist designs that sacrifice security. Conversely, an overly tight, heavy cage can make retrieving and replacing a bottle a wrestling match mid-ride. The engineering challenge is to create a structure that uses material intelligently to lock a bottle in place without excess bulk.

At Trifox, we approach this through advanced carbon fiber layup and strategic geometry. Our bike bottle holder designs, like the CBC200, start with high-modulus carbon fiber. This material offers an exceptional strength-to-weight ratio, allowing us to create a cage that is incredibly light yet structurally rigid. The rigidity is crucial—it prevents the cage from flexing and loosening its hold over time or on rough terrain.

The true magic, however, lies in the shape. Grip isn't achieved by simply squeezing the bottle tighter. It's about intelligent contact points. We mold the cage arms with a specific concave curvature and textured inner surface. This shape cradles standard-sized bottles securely, creating even pressure distribution. The result is a firm hold that resists vertical bounce and lateral ejection, even when the bottle is half-full and at its most unstable.

Furthermore, the entrance and exit of the cage are carefully flared. This design consideration is critical for usability. A smooth, wide mouth allows for easy, one-handed bottle insertion and removal—a must during a hard effort—while the narrower mid-section provides the actual retention grip. This ergonomic detail ensures the cage is not just a static holder but a functional component of your ride.

The Trifox CBC200 exemplifies this philosophy. By optimizing the carbon weave and employing a unidirectional layup in high-stress areas, we shave every unnecessary gram without compromising the cage's integrity. It’s a testament to the fact that the lightest bottle cage doesn’t have to be the most fragile. Every contour, every fiber orientation, is calculated to contribute to both retention and overall bike weight savings.

Ultimately, a great carbon fiber bottle cage is an exercise in harmony. It must be light enough to be worth the upgrade, grippy enough to be utterly reliable, and smartly shaped for seamless use. It's not just about holding a bottle; it's about ensuring your hydration is always there when you need it, without a second thought. In the balance between Grip and weight, the winning formula is precision engineering, not compromise.

For many riders, the quest for comfort leads to a simple conclusion: a softer saddle must be better. This instinct often backfires. A saddle that feels like a plush couch in the showroom can transform into an instrument of discomfort on a long ride. Why? Because true comfort isn't about maximum softness; it's about intelligent pressure distribution. The materials inside your saddle—foam, gel, and advanced composites—are engineered not just to cushion, but to create a stable, supportive platform that places pressure precisely where your body is designed to handle it.

The Problem with "Soft": The Hammock Effect

Imagine sinking into a soft sofa or a loose hammock. Initially, it feels great. But soon, your body sinks until it meets resistance, often concentrating force on your soft tissue and pelvic bones. A saddle with overly soft, uniform padding does the same. Your sit bones (ischial tuberosities) push through the soft material, bottoming out and creating intense pressure points. This lack of support can also lead to instability, chafing, and numbness. A comfortable bicycle seat doesn't invite you to sink in; it provides a firm, supportive platform to sit on.

Material Science: The Tools for Intelligent Support

Modern saddles use advanced materials to solve this problem, moving beyond a one-thickness-fits-all approach.

High-Density & Multi-Density Foam: The Precision Tool

This is the cornerstone of performance saddle design. Instead of a single soft layer, engineers use varying densities:

Firm, High-Density Zones: Located directly under your sit bones. This dense foam resists compression, providing a stable platform that prevents sinking and effectively supports your skeletal structure.

Softer, Lower-Density Zones: Placed in the surrounding areas and along the center channel. This foam absorbs vibrations and provides gentle cushioning without compromising the critical structural support of the firmer zones.

This "multi-density" approach is like having a custom-molded base layer: firm where you need support, forgiving where you need relief.

Gel Inserts: Targeted Damping

Gel is excellent at dissipating sharp impacts and high-pressure points in a static setting. However, its drawbacks are weight, poor breathability, and a tendency to create a "quicksand" feel if overused, absorbing energy and causing slight instability during pedaling. Therefore, in well-designed saddles like the Trifox Comfortable Saddle, gel is used strategically as an insert, often in the nose or specific high-pressure areas, to add a layer of dampening on top of a supportive foam base. It's a supplement, not the main structure.

Shaped & Variable-Thickness Padding: The Holistic Approach

The most advanced designs combine material density with physical shape. Through pressure mapping and biomechanical research, saddle padding is carved to be thicker in supportive areas and thinner or absent in zones that require relief (like the critical perineal area). This 3D shaping ensures the right amount of material is in the right place, working in concert with the saddle's shell to create a unified support system.

The Trifox Design Philosophy: Engineered Comfort

The Trifox PU Leather Comfortable Saddle exemplifies this intelligent approach to pressure management. It moves beyond the old "soft vs. hard" debate by focusing on structured support.

PU Leather & Resilient Padding: The high-quality PU leather cover provides durability and a slight give, while the underlying cushioning system is designed for resilience and support over many miles.

Ergonomic Shape is Key: The saddle's shape features a central relief channel, a fundamental design element that alleviates soft-tissue pressure by ensuring no contact or minimal pressure in the midline. This works in tandem with the padding to direct support to the sit bones.

Focused on Lasting Support: The goal isn't initial plushness that fades, but consistent, dependable support that reduces fatigue and hotspots, allowing you to focus on your ride, not your discomfort.

Support Over Softness

Choosing a bicycle saddle based on padding thickness alone is a common mistake. The science of comfort is about differential support—using materials like multi-density foam and strategic shaping to create a stable platform that distributes your weight efficiently. It’s the difference between sinking into a problem and sitting on a solution. When your sit bones are properly supported, pressure is healthily distributed, and soft tissues are relieved, you unlock the true potential for a comfortable bicycle seat that enhances, rather than hinders, every ride. Look for design intelligence, not just squishiness.